Hole Callouts - 2010 - counterbore callout

Each of these paths may require additional training or education, extending the learning process but also opening up new career opportunities.

While it’s possible to start as an apprentice or entry-level operator without formal education, most employers prefer candidates with at least a high school diploma and some vocational training. Self-taught skills can be valuable, but formal education often provides a more comprehensive foundation.

As CNC machinists gain experience, they may choose to specialize in certain areas or advance to leadership roles. This progression can influence the ongoing learning journey:

While technical skills are crucial, soft skills also play a significant role in a CNC machinist’s success and career progression. Developing these skills can take time but is essential:

An associate degree provides a more comprehensive education, combining theoretical knowledge with practical skills. These programs often include:

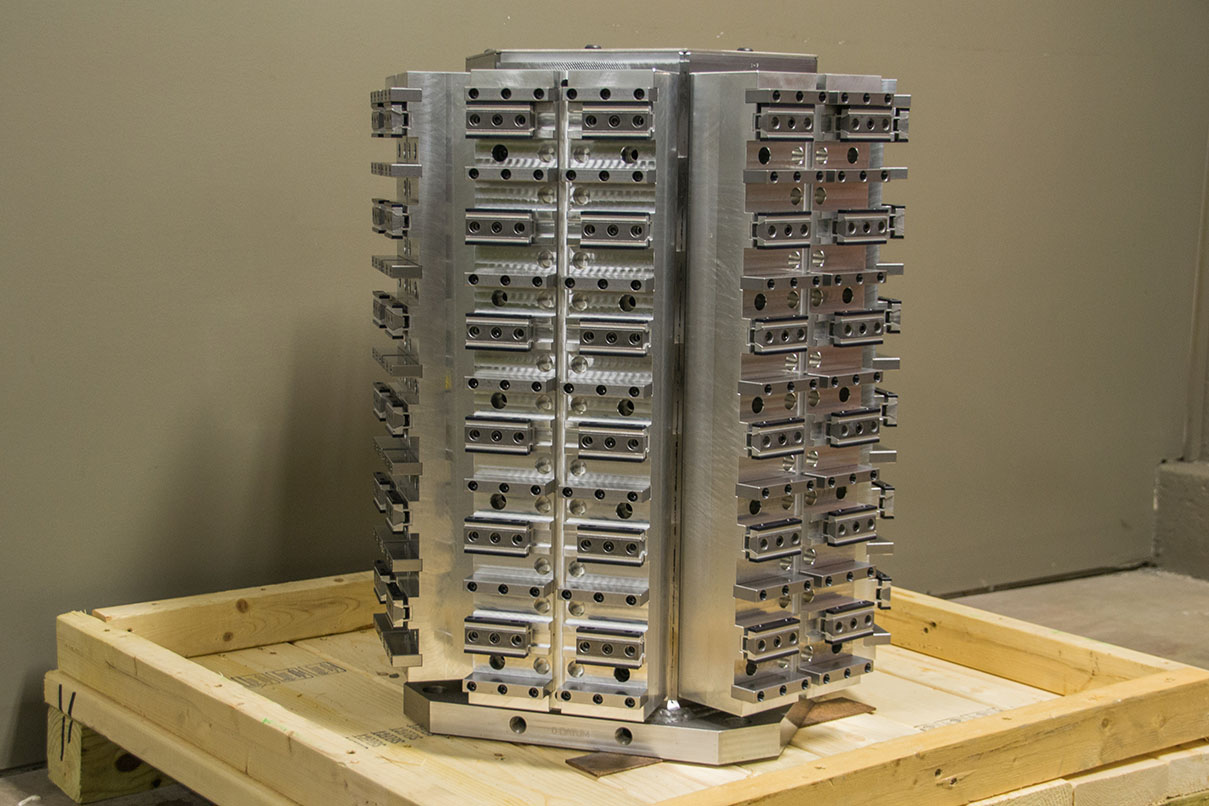

CNCfixture plate

The field of CNC machining is constantly evolving, with new technologies and techniques emerging regularly. Continuous learning is essential for CNC machinists to stay current and advance their careers. This may include:

Millingfixtures

CNC technology evolves rapidly, so continuous learning is essential. Most machinists engage in some form of skill update or new technology training every 1-2 years to stay current with industry advancements.

While theoretical knowledge and simulated training are valuable, there’s no substitute for hands-on experience with actual CNC machines. This is where aspiring machinists truly hone their skills and develop the intuition needed for troubleshooting and optimization.

Apprenticeships offer a unique blend of on-the-job training and classroom instruction. Many manufacturing companies and trade unions sponsor apprenticeship programs for CNC machinists. These programs typically include:

Before delving into the timeline, it’s crucial to understand what a CNC machinist does. CNC machinists are skilled professionals who operate computer-controlled machines to produce precision parts and components. They are responsible for:

The field of CNC machining offers a dynamic and rewarding career path for those willing to invest the time and effort to master it. With the increasing demand for precision manufacturing across various industries, skilled CNC machinists are likely to find abundant opportunities for growth and specialization in the years to come.

CNCfixture clamps

The fastest route is typically through an intensive vocational program combined with an entry-level position or apprenticeship. This can get you started in the field in as little as 6-12 months, though becoming fully proficient will take additional time and experience.

For aspiring CNC machinists, the key is to choose a path that aligns with your goals and learning style. Whether you opt for formal education, vocational training, or on-the-job learning, the most important factors are dedication, practical experience, and a willingness to continuously improve your skills.

Regardless of the educational path chosen, gaining practical experience is crucial for becoming a proficient CNC machinist. This can be achieved through:

The minimum requirement for entry-level CNC machinist positions is typically a high school diploma or equivalent. During high school, aspiring machinists should focus on:

Working with various types of CNC equipment, from basic 800W ER11 Air-Cooled Spindles to more advanced models, provides a well-rounded skill set.

The time investment required to become a CNC machinist varies based on the educational path chosen, individual aptitude, and the specific requirements of the industry or specialization. A high school graduate can enter the field relatively quickly through vocational training or apprenticeships, while those pursuing associate degrees may spend 2-3 years in formal education before entering the workforce.

It’s important to remember that becoming a CNC machinist is not just about the initial training period. It’s a career that requires ongoing learning and adaptation to new technologies and techniques. The most successful CNC machinists are those who embrace this continuous learning process and stay curious about advancements in the field.

Obtaining industry certifications can enhance a CNC machinist’s credentials and demonstrate expertise. Some popular certifications include:

CNC fixtures

Gaining proficiency across a range of equipment can add time to the learning process but significantly enhances a machinist’s versatility and value in the job market.

While not strictly necessary, having a background in manual machining can be highly beneficial. It provides a strong foundation in the principles of machining and can help you understand the CNC process more deeply. Many experts recommend starting with manual machining if possible.

While these technologies can accelerate certain aspects of learning, mastering them adds another dimension to the skill set required of modern CNC machinists.

Specializing in a particular industry can add 1-2 years to the learning process but can lead to higher-paying and more specialized roles.

This website uses cookies to ensure you get the best experience. By continuing to use this website, you’re saying okay to our cookies.

CNCfixture components

As CNC machinists progress in their careers, they often work with increasingly specialized and advanced tools. For example, high-precision operations might require the use of a 24000RPM 5.5KW ER25 Water-Cooling Spindle. Mastering such equipment adds another layer to a machinist’s skill set.

We create custom workholding fixtures for a wide range of applications to save you time and increase profitability on any volume job.

Remember, the journey to becoming a CNC machinist is not just about reaching a destination; it’s about embracing a career of continuous growth and innovation. The time you invest in learning and perfecting your craft will pay dividends in job satisfaction, career opportunities, and the pride of creating precision components that play crucial roles in countless industries.

Mastering the use of such equipment can take additional time but greatly enhances a machinist’s capabilities and value in the industry.

Many technical schools and community colleges offer vocational training programs specifically designed for CNC machining. These programs provide hands-on experience with CNC equipment and cover topics such as:

Learning to work with these advanced tools can extend the learning curve but also opens up opportunities for more complex and high-value projects.

The journey to becoming a proficient CNC machinist is a rewarding one that combines technical skill, creativity, and problem-solving. While the basic skills can be acquired in as little as 6-12 months through intensive programs, truly mastering the craft often takes 3-5 years of hands-on experience and continuous learning.

Becoming a CNC (Computer Numerical Control) machinist is an exciting career path that combines traditional craftsmanship with cutting-edge technology. For aspiring CNC machinists, one of the most common questions is: how long does it take to become proficient in this field? The journey to becoming a skilled CNC machinist can vary depending on several factors, including educational background, training programs, and individual aptitude. In this comprehensive guide, we’ll explore the various paths to becoming a CNC machinist and the time investment required for each.

CNCfixture manufacturers

These certifications typically require a combination of work experience and passing an exam, which can add to the overall time investment but significantly boost career prospects.

Understanding and operating advanced CNC equipment is a crucial part of a machinist’s skill set. For instance, working with high-performance spindles like the 24000RPM 3KW ER20 Water-Cooling Spindle requires specialized knowledge and experience.

Math is crucial in CNC machining. Strong skills in geometry, trigonometry, and algebra are essential for understanding machine programming, reading blueprints, and performing necessary calculations. The better your math skills, the quicker you’re likely to progress in your training.

0086-813-8127573

0086-813-8127573