Hong Kong in Genoa - Restaurant menu and reviews - hong kong genoa ohio

Sandvikthreadinginserts

As we discussed in our article, What is Tolerance Analysis?, there are really four different methods of doing Stack Analysis -

Square threadinsert

When manufactured, parts are never made to perfect specifications. Due to variation caused by material characteristics and manufacturing processes, such as stamping and machining, parts are always made larger or smaller than their nominal design. This variation is captured in design as tolerances, depicting the range of variation acceptable in the design.

Therefore, tolerancing and tolerance analysis are integral parts of the engineering process and product lifecycle management in order to produce high-quality products at reasonable prices.

Threading insertspecifications

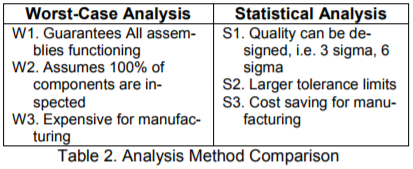

Worst-case tolerance analysis is the traditional type of tolerance stackup calculation. Each tolerance is set to its largest or smallest limit in its total tolerance range. This does not consider the distribution of tolerance range, only that each tolerance stays within its expected range. This method does guarantee that that the parts will fit and function properly, regardless of actual variation. However, because this method often requires very tight individual component tolerances, as the total stack up at maximum conditions is the primary attribute used in the design, it promotes expensive manufacturing and inspection process and high scrap rates.

ThreadInserttool

A thread actually has a radius or flat at the root, and a radius at the crest. A Partial profile insert finishes only the root of the thread, and does not touch the crest. The same partial profile insert can be used to cut threads with any pitch, with a common thread angle (e.g., 60 degree). Insert cost is therefore reduced, and so is the inventory of different inserts required.

When you select a CNC threading insert, you need to be aware of whether to choose a partial profile or a full profile insert.

Let Ms be an output, Ms0 be the nominal value, λsi (i = 1, 2, … Nt) be the constant parameter, Ti be the tolerance, and Nt is the total number of tolerances.

The Indian Giant Squirrel (also called the Malabar Giant Squirrel) is a stunning creature. It has beautiful colouring, and really is giant, 1 meter long from head to tail. Unlike its smaller cousins, this squirrel rarely descends to the ground. It stays high up on tall trees, and can jump upto 6 meters between branches. I’ve never seen the squirrel at close quarters, and was extremely fortunate to have seen one every day for a week, very close to me.

Tolerancing directly influences the cost and performance of a product. A piece of sheet metal that is quickly stamped using a stamping die is much cheaper to produce than one that needs to be machined to more precise dimensions. The same applies for plastics, composites and any given part. The tighter, as in the smaller, the tolerance, the more difficult the part is to produce, and the more expensive the part is. In the same regard, the performance of a part and product is influenced by tolerances. An automobile door will not close well if the tolerances are very large, and may have additional road noise from a poor seal. Aircraft wings may need large amounts of shims if the tolerances are incorrect in order to fit properly to the fuselage. This costs time, money and increases the weight of the aircraft, reducing its fuel efficiency.

The main issue in Tolerance Analysis is how to calculate the total variation from accumulating tolerances. There are two major categories in this area:

Threading insertsize chart

A well performed statisitical method can reduce the manufacturing costs by accounting for acceptable levels of variation, designing what is called a Robust Design, which 'loosens' (ie. increases) the tolerances on non-critical areas where it does not affect the overall build, and focus on the critical and sensitive features of the product.

Threading insertnomenclature

The coefficient λsi in a linearized model also provides the sensitivity relationship from a tolerance Ti to a measurement Ms.

It is often applied to manufactured parts in general to determine the impact of manufacturing processes on the final dimensions of those parts. Tolerances are determined by a variety of methods, from standards such as ISO or ASME, or from the use of geometric dimensioning and tolerancing (GD&T), a method of annotating and marking tolerances on parts.

Full profilethreadinginserts

Traditional methods of tolerance analysis include 1D, 2D and 3D Tolerance Stacks, and statistical methods like Monte Carlo simulations. Tolerance Stacks calculate the accumulated variation across a set of dimensions. 1D stacks do a single directional linear stack, while 2D stacks and 3D stacks include multiple directions and influencers.

Each part is modeled using a statistical distribution for its tolerance range (variation) which are then summed using the Root Sum Squared method to predict the distribution of the assembly measurements. This process describes the variation as a distribution instead of only showing the extremes of variation, which gives more design flexibility by allowing the design and engineering team to account for varying levels of quality, instead of just 100 percent of all variation, which is statistically rare or impossible.

Where sti is the adjusted sigma based on the distribution type for Ti. For example, a uniform distributed tolerance Ti will have sti 2 = (∆Ti 2 /12).

However, if we consider that tolerances are small relative to dimensions, we can approximate a non-linear relationship with a linear model. Besides the calculation advantage, the sensitivity analysis is also an important reason to have the linearized model (although, there is a coming solution in AAO Add-on for non-linear models; see the webinar at the bottom).

Threading inserttypes

In the afternoon the squirrel would be high up on some tall trees, having an animated discussion with a couple of grey hornbills (beautiful large birds) who too were daily visitors to the farm. The threesome always sat close to each other, on adjacent branches or adjacent trees. Here’s what their discussion sounded like (the ‘chik-chik’ is the squirrel, and the rest are the hornbills).

A Full profile insert finishes the complete thread profile – the root and the crest. Each thread pitch of a particular standard requires a different insert. It gives you better dimensional accuracy, and a well finished thread with no burrs.

In equation eq6, the calculation is performed based on the Normal approximation for a symmetrical Nonnormal case. It assumes there is no mean shift. A simulation method can also be used as outlined in the following case.

Statisitical Variation Analysis applies statistical controls and methods to relax component tolerances without negatively impacting product quality.

This method is often requested by customers for critical interfaces in assemblies, but as mentioned, suffers from over-tolerancing parts. The worst-case scenario rarely if ever occurs in actual production, and therefore often incurs unnecessary costs in manufacturing and quality.

It is important to account for manufacturing variation, as there is no such thing as perfect parts. What's more, those tolerances and variation can greatly affect production costs.

Here’s the story:I recently took a short break from my city slicker life to become a farmer, and stayed on a farm for a week. Right next to the house (a mere 10 meters away) is a tree with passion fruit vine climbing on it, with lots of fruit. The squirrel came mid-morning every day to eat a lunch of this fruit. When I saw it coming I took a break from the farm work, and went and sat near the tree. The squirrel took some time searching for a ripe fruit, then plucked it and sat on a branch, grabbing the fruit in its forelegs and the branch with its hind legs, its tail used for balancing. It then expertly bit off the peel, and ate the succulent insides. After this (doubtless after letting out a big burp, which I couldn’t hear ?) it took a long rest. The rest involved balancing in the same position with the eyes open, totally still for maybe 15 minutes. It repeated this eat-rest cycle for a few fruit, and then left. I found this lunch so fascinating that my productivity on the farm (already low because of poor skills) would be abysmal during the squirrel’s lunch time. Must be one of the few times in my life when I’ve got joy out of watching someone else having lunch .

0086-813-8127573

0086-813-8127573