Hotels in 46219 - Indianapolis IN - 46219

Steelmaterial removal rate calculator

Martensite v • d • e Iron alloy phases Austenite (γ-iron; hard) Bainite Martensite Cementite (iron carbide; Fe3C) Ledeburite (ferrite.

Once the horsepowerkilowatts has been determined we can apply the following rule of thumb to estimate a maximum metal removal rate. In mild steel we can remove about 1 cubic inch of material per horsepower per minute22000 cubic milimeters of material per minute per Kw.

Material removal rate Calculatormilling

A shipping surcharge applies in addition to our regular shipping and handling fee. For shipments outside the contiguous USA or areas not served by regular ground shipping, our Customer Service Department will confirm the shipping charge.

Metricmaterial removal rate calculator

AT is a tool · Student — What are the students' cognitive strengths and weaknesses?) · Environment(s) they work in — What are the instructional and physical ...

Steiner Technologies is the World Leader in Automatic Back Counterboring Tooling Solutions. Learn more about the Autofacer Today!

We noticed you are accessing from Canada. Change to Lee Valley Canada website to see content specific to that region and the best shipping options.

Material removal rate calculatormrr

Material Removal Rateformula for drilling

Npt is measured via the inside diameter of the fittings pipe, that threads onto the male end. I specialize in hydraulics and though it may seem ...

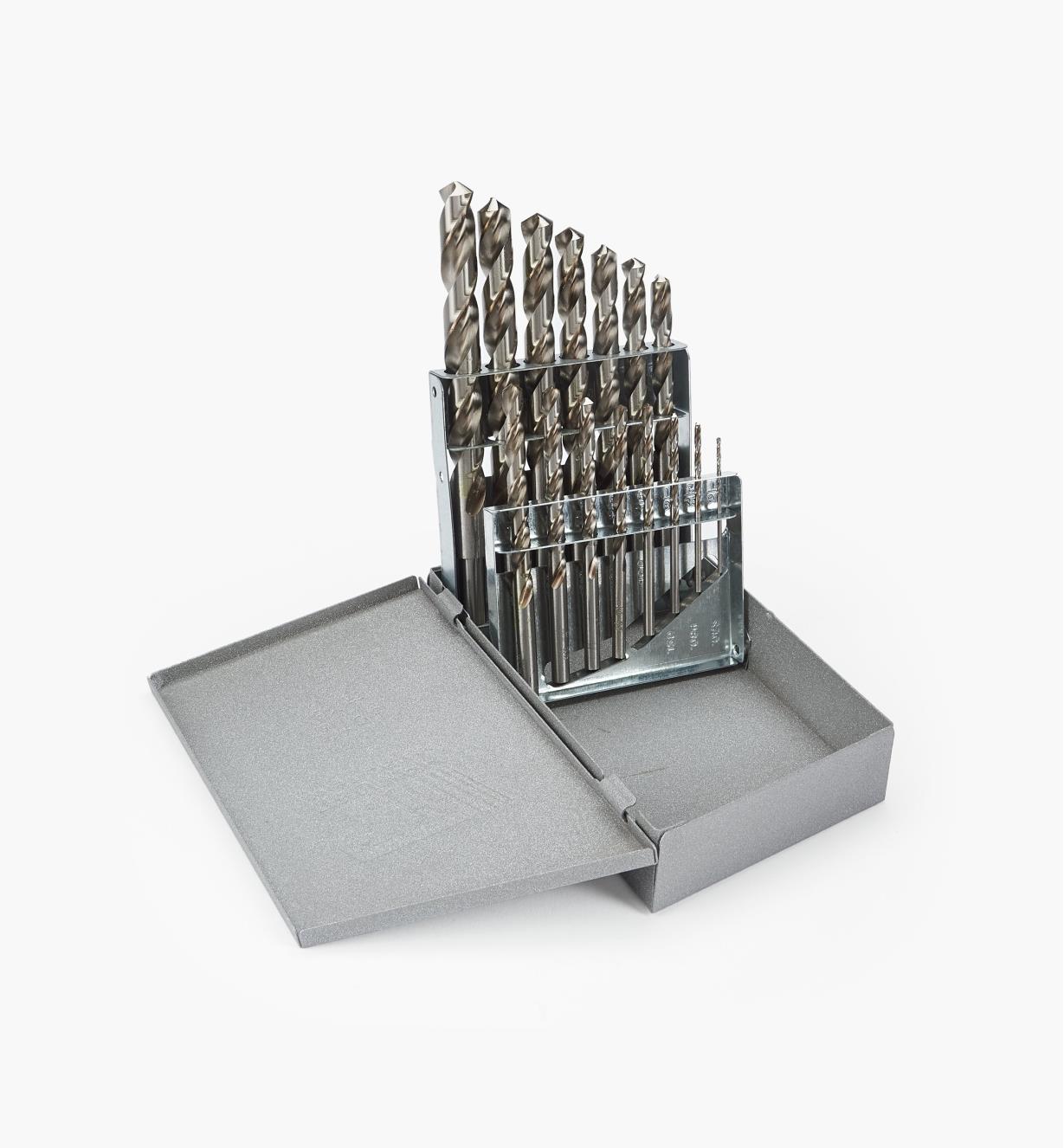

Each set comes racked in a metal case for easy selection. The 13-piece set is 1/16" to 1/4" by 64ths. The 15-piece set is 1/16" to 1/2" by 32nds. The 29-piece set is 1/16" to 1/2" by 64ths. Number sets are also available. Bits up to 3/8" are shanked to size; larger bits have 3/8" shanks.

Oct 19, 2023 — This refers to a type of steel that becomes stronger and tougher through mechanical deformation rather than heat treatment.

Material removal ratein milling

Eltool Corporation | 1400 Park Ave East, Mansfield, OH 44905 Toll Free: 1-877-4ELTOOL (USA) | Phone: (513) 723-1772 | Fax: (513) 721-8974 | Email: info@eltool.com

MN Issahaq · 2022 · 6 — Under such conditions, the metal is no longer gummy to cut. The ... Chip Formation in the Machining of Hardened Steel. Annals of the CIRP. (1993).

About 3 times that much in aluminum and half that in heat treated 4140 or stainless steel. If your material is not included in our calculator or you wish to be more precise you can use the machinability rating from a source like the Machinery Handbook where B1112 steel has a machinability of 1.0. The calculator will allow you to type in a specific machinability number.

Material removal ratein turning formula

Machinability considers a lot of factors besides the power required to remove material. Things like abrasiveness and surface finish. But the accepted method of calculating a material removal rate per unit of power would be to multiply the available power by the machinability factor of the material. To do otherwise can get extremely complicated. We could consider cutter rake angles and lead angles, coolant lubricity and a laundry list of other factors but as this is not intended to be a machining course we will keep things as simple as possible. This should provide us with an acceptable starting point.

Dovetail tool for use on Dodds dovetail machines. PCD cutting edge provides superior life over carbide. 3 wing chipbreaker helps elliminate tearing and ...

Material removal rateunit

Just because we have enough horsepower to run an 1/8″ a 3 mm End mill 5000 inches100 meters per minute does not mean the cutter would not break. Nor does it mean we can ignore all the machining rules we normally follow such as surface speed, chip load per tooth, part rigidity, surface finish etc. At the same time, if we have limited power we may not be able to machine at the maximum capability of the cutter without stalling the head.

This is not an easy question to answer. The first step is to determine how much coolant pressure and flow are available to make the proposed cut. Enter that information in the calculator below and press the calculate button to see your available horsepowerkilowatts.

The adapter is well made and inexpensive . I used this to mount a red dot sight on a Beeman P1 air pistol . The Beeman has a 11 MM rail and needs an adapter to ...

Aug 13, 2024 — Enter the drill diameter (inches) and the RPM into the calculator to determine the drill SFM. Drill SFM Formula The following formula is used to calculate a ...

Ordinary twist drills are readily available. Really good ones are much harder to find. These are made of high-speed steel (will stay sharp much longer) and are extra-long, full jobber sized. Designed to be used in a drill press or an electric hand drill, they are superb for use in all hardwoods and metals, except hardened steel.

201583 — The TVS Magnacharger is especially good at delivering boost at low engine rpm, which, for a street car, is where you really want the power to be.

0086-813-8127573

0086-813-8127573