House Prices in Mill Corner, Fleet, Hampshire, GU51 - mill corner

Let’s take a look at the hardness of each type of drill bit, as well as some of the things to keep in mind when choosing between carbide and cobalt drill bits.

We have multiple locations around the U.S., ensuring that you can get your tools treated in a timely manner. By having your carbide drill bits treated in advance, you can cut down on delays and downtime later.Contact us today to get a free quote and learn more about the process!

That’s why they’re primarily used in automated equipment, and aren’t designed for use in hand drills and other manual processes where they can snap under pressure. You’ll find them in a range of industries, such as automotive and aerospace factories, where only the hardest drill bit tips will do.

Whilst suffering with his own health with vascular insufficiency of the lower legs, Cushing declined the offer of amputation and instead found that cessation of tobacco (he was an excessive smoker) hugely improved his health within three weeks. Whilst suffering lapses, he did subsequently lecture on the benefits of smoking cessation despite it being many years before the habit was medically denounced.

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Hardness refers to the surface of the material – essentially, how easy it is to scratch or dull its surface – while brittleness refers to how easy it is to break. So while carbide drill bits are very hard, and can cut through some of the most difficult materials, they’re also brittle and can break if not used properly.

Perhaps his most enduring contribution to clinical medicine is Cushing Syndrome, described in 1932. It was Cushing himself who deftly realized the collective signs of a small series of patients whilst preparing the background reading for his 1930 Lister Lecture on pituitary physiology. This, for the first time, more completely explained other researchers’ partial explanations, for example, the term ‘diabetes of bearded women’. Cushing syndrome is the consequence of hypersecretion of the adrenal cortex due to any aetiology, although the original case series described three instances of pituitary basophilic adenomas.

Even the most high-quality drill bits are going to wear down after a while, at which point you have to decide whether it’s better to sharpen them or replace them. Due to the high cost of carbide drill bits, it’s probably worth your while to sharpen them.

Titanium drill bits are usually made out of steel with a titanium coating, so they aren’t as strong as cobalt drill bits, and are liable to lose their coating over time.

Carbide vs cobaltdrill bit

Or call 818-445-3030 to speak with someone now. Contact Us Form Name Email* PhoneIndustry How Can We Assist You?*PhoneThis field is for validation purposes and should be left unchanged.

Carbide inserts can be used to work with cast iron and steel, as well as bronze, copper, aluminum, and other hard or abrasive materials.

First, we need to understand how drill bits are actually constructed. Many drill bits aren’t made of a single element, but are made out of a steel alloy. Some drill bits are tipped or coated with a second material to make them stronger or more resistant to rust.

Cushing was an innovator but not particularly inventive. As such, he repudiated the sets of ‘Cushing’s Brain Instruments’ sold by Codman & Shurtleff during and after the war as unauthorized knock-offs.

Carbide drill bits are made out of tungsten carbide, although they often contain small amounts of other materials, such as cobalt, to reduce their reactivity with iron. You can usually find carbide drill bits in one of two forms: carbide-tipped or full-body.

It might seem counter-intuitive, but carbide is both the hardest drill bit – up to five times harder than steel – as well as the most brittle. That’s because, when it comes to tools, hardness is just one of the factors that determines a material’s overall strength.

This Applied Science video shows how you can do it at home with liquid nitrogen, but for best results, we recommend choosing a professional.

Having established himself as a surgeon with an early interest in neurosurgery, Cushing was one of the very first advocates of the Riva-Rocci sphygmomanoter, in around 1900, as a means to measure peri-operative blood pressure. The device was effectively the earliest method of measuring blood pressure accurately, developed by an Italian paediatrician, Scipione Riva-Rocci, a few years previously. This new monitoring system was soon adopted, and coupled with the newer surgical techniques, allowed safer and more complex surgery to be undertaken.

Because they can handle temperatures as high as 1100 °F, cobalt drill bits can be used in high-heat settings. The higher the percentage of cobalt, the more heat-resistant it will be; at the same time, a higher percentage of cobalt means it will be more brittle.

CarbideDrill bits

However, while high-speed steel is capable of many types of maintenance tasks, it isn’t suitable for more industrial uses, which is where other materials come in.

Cushing died in Connecticut, from complications of a myocardial infarction. Interestingly, as the pioneer of modern neurosurgical practice, his autopsy revealed a colloid cyst in the third ventricle.

Cushing went on a fishing vacation in August of 1914, and by the end of this vacation, war had broken out. Cushing headed the first Harvard Unit of 13 surgeons and 4 nurses and left America on 22 March 1915 headed for Gibraltar and on to Paris where they ran the ‘American Ambulance’ before returning in June. Several further stints were spent in base hospitals during the subsequent war years, and he was eventually assigned as senior consultant in neurological surgery for the American Expeditionary Forces in Europe. During this time, he treated Lieutenant Edward Revere Osler, who had been fatally wounded during the third battle of Ypres, and was the son of Sir William Osler. Later, Cushing would write a two-volume biography of Sir William Osler, becoming a classic, and winning him a Pulitzer Prize in 1926.

Whether you rely on carbide drill bits, inserts, cutters, end mills, or any other tool, you can increase their lifespan and reduce downtime with cryogenic treatment.

Carbide vs cobalt vstungsten

Carbide tips can drill through hard, non-metallic materials like masonry, while full-body drill bits are primarily used in automated processes.

Carbide vs cobaltfor metal

Cobalt drill bits can be sharpened without losing their strength. They also have a relatively long lifespan, making them an affordable option despite their higher cost.

Cobalt vs carbidedrill bits for steel

However, you can’t simply use any sharpener on your carbide drill bits. You’ll need the right tool for the job, which in this case is a diamond-surface grinding wheel.

James F Doyle, Intensive Care Unit and Surrey Perioperative Anaesthesia & Critical Care Collaborative Research Group (SPACeR), Royal Surrey County Hospital NHS Foundation Trust, Egerton Road, Guildford, UK Email: james.doyle4@nhs.net

Tungstencarbide vstitaniumvs cobaltdrill bits

His extraordinary medical career spanning over 40 years, including operating on over 2000 brain tumours, and his discoveries and innovations, have helped make Neurology and Neurosurgery the respected specialties they are now.

In some cases, the drill bit will be made out of a less brittle material, and only the tip will be made out of carbide. That way, you get the hardness of carbide on the drilling surface, with the stability of a less brittle material to prevent the bit from breaking.

Secure .gov websites use HTTPS A lock ( Lock Locked padlock icon ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

They stay sharper longer than cobalt drill bits do, and they have a higher cutting speed. They can also handle higher temperatures.

But the best drill in the world won’t be much use to you if its drill bits aren’t up to the job. No matter how powerful your drill is, what really determines its capabilities is the bit.

Cobalt drill bits have a recognizable gold color. Although it looks like a coating, it’s not, and is the result of a “baking” process that the drill bits go through. It may wear off with use, but this won’t impact the quality of the drill bit.

Drill bits that are cryogenically treated have been shown to drill twice as many holes as drill bits that aren’t, before needing to be replaced. The treatment process changes the carbide’s microstructure, resulting in drill bits that are 7% harder.

The type of drill bit that you need depends on several factors, including the material that you’re cutting, but also the length of drill bit that you need. Longer drill bits can be more brittle and break easily, even if they’re made out of a strong material.

Then there’s carbide, which in this case is actually tungsten carbide and is a compound of tungsten and carbon. Carbide drill bits are often made out of steel with a carbide tip. They’re commonly used in industrial applications due to their superior strength. They can cut through concrete, masonry, tile, and more.

Cobalt drill bits are ideal for when you need to drill through hard metals. They come in two grades: M35, which is made of 5% cobalt, and M42, which is made of 8% cobalt.

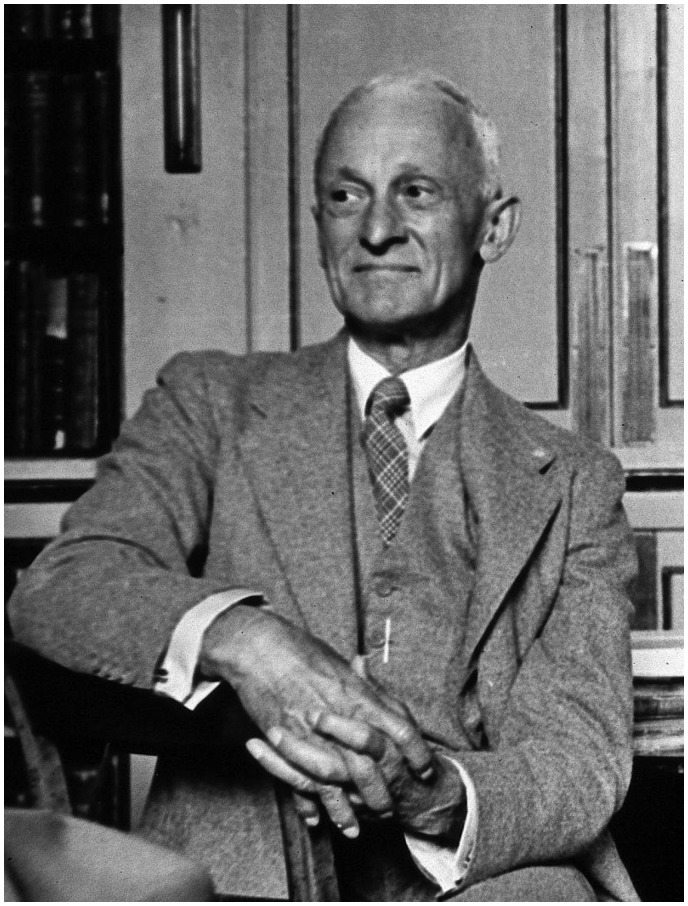

Harvey Cushing is well known as being the father of modern neurological surgery and his portrait brands the American Association of Neurological Surgeons. He was the youngest of 10 children and from medical lineage with his father, grandfather and great-grandfather all being general medical practitioners. The details of his life and work are particularly well documented as a result of his obsessive letter writing and record keeping.

Dr Cushing began his medical career as an intern in 1895 at Massachusetts General Hospital (MGH) spending a year in the surgical service. An intern, as opposed to an extern, would live and work in the hospital for the year on minimal wage and for long hours. As an intern, Cushing wrote a letter to his mother: ‘Everyone is much excited over the new photographic discovery … we won’t be able to have secrets anymore’, referring of course to the newly discovered technology of X-rays by the German physicist Röntgen. Within three months, Cushing had helped secure X-ray apparatus for the MGH out-patient department.

TungstenCarbideDrill Bits

Cryogenic treatment is a one-time process that involves cooling the metal to cryogenic temperatures (–238 °F or below) with the help of a cryogenic liquid or gas. Then, it can be heated back up to a higher temperature and allowed to cool naturally.

If you don’t have a grinding wheel at your disposal, then it may be more cost-effective to hire a professional to do it for you. So while you can sharpen carbide drill bits yourself, it requires specific tools and you may need some training to get it right.

Carbide vs cobaltreddit

CTP Cryogenics has over 30 years of experience in the field of thermal processing. We work with carbide tools of all kinds, using a proprietary treatment process that’s tailored to your specific use case and industry.

Drills are one of the most important items in any toolkit. Depending on your industry or product, your drills need to be able to cut holes in wood, plastic, metal, and more – all while adhering to precise measurements and quality standards.

How do you know if you should use a carbide or cobalt drill bit? Although both types of drill bits have their uses, they can’t be used interchangeably, so it’s important to use the right one for the task at hand. Let’s take a look at the pros and cons of each:

This is because the temperatures that your drill bits are subjected to when they’re first made has a long-term impact on the quality of the finished product.

Since each tool has a specific concentration of tungsten carbide, it may take multiple tries to find the right treatment process for your drill bits.

Other tools use carbide inserts, which are often triangular or diamond in shape, and are inserted into a tool made out of another metal, such as carbon steel. The benefit of this approach is that the tool is less brittle overall, and you can rotate the carbide inserts to expose a different edge when the cutting side becomes dull.

Most metal products are forged or cast at high heat, after which they must be cooled to room temperature. Traditionally, this was done by quenching them in water, but modern cryogenic techniques provide a more controlled treatment process.

Cushing’s reflex came about from Harvey Cushing’s studies of the brain’s reaction to compression, whilst in Europe in 1901 and 1902. His studies were more detailed than those of other researchers; the brain’s reaction had been known for the preceding 20 years, and even though Cushing’s Law was not particularly original, Cushing was able to describe in detail the timings, stages and local variations of the observations associated with increased brain pressure and offer a much more detailed description of the pathophysiology of Cushing’s reflex. His research showed that increased intracranial pressure leading to cerebral herniation and fatal brainstem compression resulted in increasing systolic and pulse pressure with bradycardia and respiratory irregularity; his detailed descriptions allowed the phenomenon to bear his name, rather than the previous researchers.

In this article, we’re going to take a look at the key characteristics of a drill bit – including the metal it’s made out of, its tip, and its coating – as well as how you can use cryogenic processing to make your drill bits stronger and longer-lasting.

Cobalt drill bits are made with a steel alloy containing 5-8% cobalt, so they can be used to cut into steel and other hard metals like cast iron.

High-speed steel (HSS) is commonly used in drill bits and power saw blades because it’s affordable and capable of cutting through wood, plastic, and soft steel. HSS drill bits cut faster than other types of steel, which is where they get their name.

Official websites use .gov A .gov website belongs to an official government organization in the United States.

By the end of the war, Cushing had been awarded Companion of the Bath by the British government, and the Distinguished Service Medal by the U.S. Army.

Another option is to treat your drill bits cryogenically to reduce wear and make them last longer without the need for frequent sharpening. Although cryogenic treatment is known for its use in manufacturing, including the treatment of aerospace and automotive parts, it can be used to extend the life of cutting tools as well.

0086-813-8127573

0086-813-8127573