how do I calculate lathe rpm using surface speed/part ... - lathe sfm calculator

Full profilethreadinginserts

STRAIGHT REAMER, 8 FLUTE, 1-1/16" , 11" OAL ,STRAIGHT SHANK , FLAT BOTTOM · STRAIGHT REAMER, 8 FLUTE, 1-1/16" , 11" OAL ,STRAIGHT SHANK , FLAT BOTTOM.

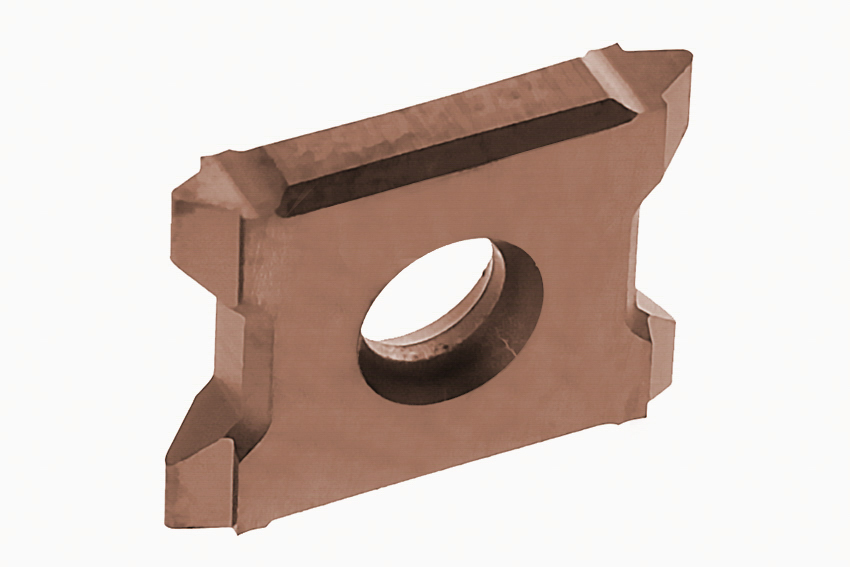

45 DegreeThreading Insert

Learn the latest on Cornerstone Building Brands' acquisition of Harvey Building Products, enhancing exposure to repair-and-remodel channels.

All milling machines are dangerous, increasing the horsepower increases this danger. It is your responsibility to insure fit and proper application. We make no guarantee of safety, application or that this product is suitable for your intended use.Our 750W motor exceeds the capabilitys and stability found in most mini milling machines.Use at your own risk. Our liability is limited to the purchase price of this item.

Nov 28, 2013 — What are square inserts used for, what are the advantages of the square shape. ... The disadvantages as a turning insert is that it's not ...

Nov 24, 2005 — 1,000 rpm in stainless 2-3k in aluminum, finnish passes is the mills redline at rapid traverse. we paid about $300 for the face mill about 10 ...

Threading inserttypes

How to increase tool life by improving wear resistance through edge honing, radiusing and rounding.

2022420 — Carbide Drill Bits vs. Cobalt Drill Bits Cons ; More costly than cobalt. Do not last as long as carbide drill bits hardened steel requiring ...

Threading InsertSize chart pdf

Shop Drill Predrill and Countersink Bits online at TradeTools. We pride ourselves on being Australia's number one tool shop. Buy our Drill Predrill and ...

16 ERThreading Insert

Shop Grainger Canada for quality Routers, Bits & Wood Shapers products. Grainger Canada has been Canada's premiere industrial supplier for over ...

From opening bottles to adjusting screws, the PocketMonkey multi-tool helps you conquer everyday tasks easily. Made in the USA from heat-treated stainless steel ...

See the Videos in the photos of this listing:Video 1 is the 2024 control unit operation.Video 2 is the instal instructions and test results of the base unit.Note base controler produces the same torque and speed but does not have e Stop or reverse on the fly.See the original build and test results on YouTube here:Note this system is no longer offered.https://www.youtube.com/watch?v=vnDJnGCIG-sThe new machined motor face plate and the new anodized pulley is included.See video. The additional bolt pattern was not designed for the milling machine kit. It is for lathes. However it is within 2 mm. Several builders have chosen to simply slot them with a round file.This allows instaltion of the new motor in the original motor holes.Results of adapting Our 1 hp servo motor to the Little Machine Shop Belt Drive:

Threading insertspecifications

Limited 180 day parts warranty. Labor is buyers responsibility: See details, what's covered and for how long etc below. Shipping both ways for all parts returned for warranty is the buyers responsibility. Parts returned will be inspected for unique identification mark and or abuse. If found to be abuse or missing the identity mark, no warranty exchange part will be provided and buyer will be required to pay shipping to get their parts back. Warranty exchange parts may or may not be new but instead refurbished or demos that I have from previous builds. Warranty starts on the day our records show the system as paid and not the date the item is actually received.

Sandvikthreadinginserts

1/16" Down Cut End Mill x .300" Depth Two Flute Down Cut Carbide End Mill M192 Regular price $10.95 USD Regular price Sale price $10.95 USD

Threading insertsize chart

This kit is for those who already instaled The Little Machine Shop belt drive conversion on their Mini Milling Machine and want all the features seen in our 2024 systemWe recomend you purchase our complete kit with toothed belt as the performance is superior. however if you already purchased the LMS belt drive and want to use it, this kit will get you there.

Servo Motor. - I will exchange a defective servo motor for up to 180 days. Buyer must return the motor + the control unit + the speed control switch for inspection and testing. Additionally original packaging such as Styrofoam package inserts must be used to return these parts.

Buyer to provide tracking # and shipping company name to be e mailed to servomotorkit@gmail.com within 36 hours of when issued.

Swapping out parts will result in no refunds, all warranty's voided and no new orders accepted. Try honesty instead, we will be happy to assist and find a solution that keeps both of us happy.

Buyer provides tracking number that shows the item is in possession of the return shipping company before the 30 day time period runs out.

0086-813-8127573

0086-813-8127573