How Do You Use an Angle Tool When Woodworking? - cutting angle tool

Saw bladesharpening tool

Circular saws are a popular tool in woodworking and construction industries. However, over time, the blades of these saws tend to lose their sharpness, impacting their cutting efficiency. This leads to an important question: Is it worth sharpening circular saw blades or is it more cost-effective to replace them altogether? In this blog post, we will delve into the pros and cons of sharpening circular saw blades to help you make an informed decision.

Cutting Performance - The primary purpose of a circular saw blade is to deliver precise and efficient cuts. A sharp blade ensures smoother cuts, reduces material wastage, and enhances overall productivity. When blades become dull, they can produce rough or uneven cuts, leading to lower-quality work. Sharpening circular saw blades restores their cutting performance, allowing for cleaner and more accurate cuts. Therefore, if achieving optimal cutting performance is crucial for your projects, sharpening the blades is a must.

Sharpen circular saw bladewith dremel

Circular saw bladesharpening near me

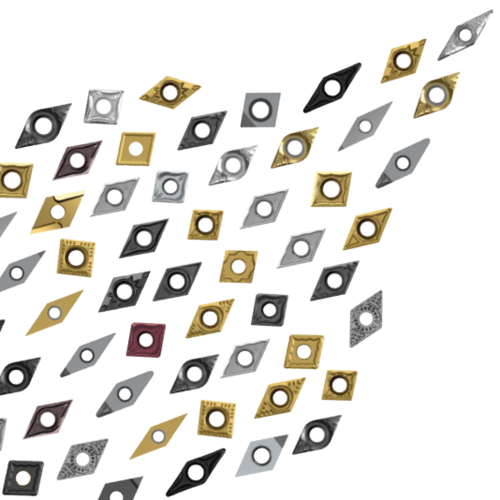

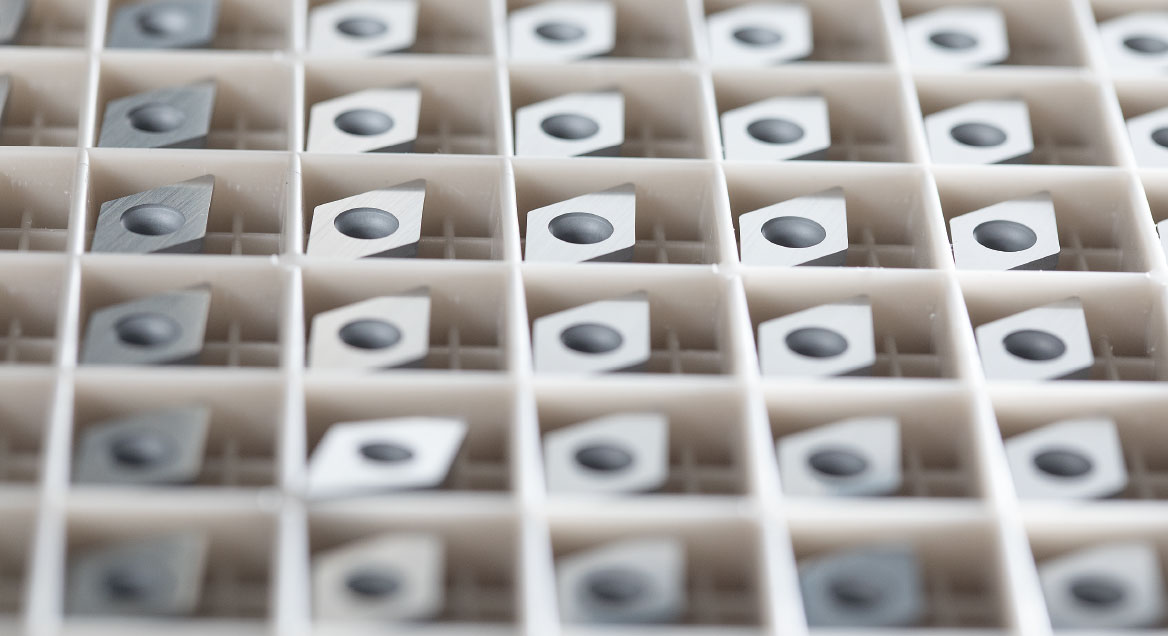

Ideal for long-chipping materials, thin-walled components and optimal surface qualities – high-positive indexable inserts with sharp edge executions from ARNO.

Blade Longevity - Replacing circular saw blades too frequently can be expensive in the long run. By sharpening blades, you can extend their lifespan and maximize their value. Regular maintenance and sharpening can help prevent premature wear and tear, increasing the longevity of the blade. However, it is essential to remember that blades have a limited lifespan, and excessive sharpening may compromise their structural integrity. Balancing the frequency of sharpening with the overall condition and wear of the blade is crucial to ensure safety and effectiveness.

From precision machining of thin-walled workpieces to roughing of large components, ARNO has the optimum indexable insert for every application.

Howtosharpen circular sawblades by hand

Ideal for fine machining of high-temperature materials and stainless steels: high-positive indexable inserts with edge-honed executions from ARNO.

For perfect surface finishes on steels up to 52 HRC, we also offer a combination of the NFS chip-breaker and AH4205 type.

Sharpen circular saw bladewith grinder

Time Efficiency - Time is a valuable resource, especially for professional woodworkers or construction workers with tight project deadlines. Sharpening circular saw blades can be time-consuming, especially if done manually. On the other hand, purchasing a new high quality Circular Saw Blade can cost 2-5 times the cost of sharpening a saw blade.

Deciding whether to sharpen or replace circular saw blades ultimately depends on several factors, including cost, time efficiency, cutting performance, and blade longevity. While sharpening can be a cost-effective and environmentally friendly option, it requires time and effort. Evaluating these factors based on your specific needs and circumstances will help you make an informed decision that aligns with your budget and project requirements.

If you are looking for a cost-effective alternative for hard turning, look no further – the type AH4205 is ideal for steels up to 52 HRC. Especially when combined with the NFS geometry, this type achieves the highest surface qualities down to RA 0.2 μm with excellent tool life. This is due to the very hard base substrate, a PVD multilayer coating, excellent wear and temperature resistance as well as optimum chip breakage and evacuation.

Howtosharpen a circular saw bladewithafile

Cost Considerations - One of the primary factors to consider when deciding whether to sharpen circular saw blades is the cost. Sharpening blades can be significantly cheaper than buying new ones. Professional sharpening services, like Pro Sharpening Supply located in Bastrop Texas, offer cost-effective alternatives to blade replacement. However, the frequency of sharpening required depends on the quality of the blade and the intensity of usage. If a blade has incurred extensive damage or has worn down significantly, the cost of sharpening might approach or even exceed the cost of purchasing a new blade.

Why hard turning? Because it is very efficient, guarantees extreme tool life and excellent surface qualities, and protects the environment. Why ARNO? Firstly, because our coated CBN inserts stand out due to their incredible hardness (up to 65 HRC) and heat resistance, which is achieved via an even distribution of CBN grain and binder as well as a high degree of purity. And secondly, because ARNO offers the optimum solution for every application via seven insert types and two chamfer designs – even for extremely hard materials and the highest cutting speeds.

0086-813-8127573

0086-813-8127573