How Does a Lathe Work? Everything You Need To Know - lathe machining

High Temp. Fiberglass Composite Layup Molds: Designed with shrink factor and overbend to customer specificied cure cycle. EOP and excess scribes incorporated per customer needs/requirements.

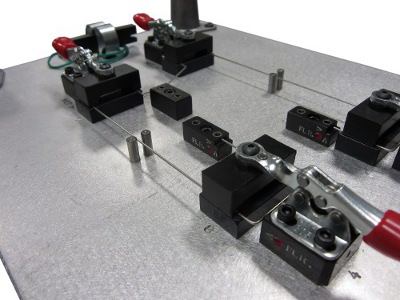

Full attribute fixtures for stamped and molded parts. Tooling Experience : • Checking Fixtures • Assembly Fixtures (Manual or Automatic) • NC Blocks and Tooling Components • Dimensional Verification of Parts • Low cost wood and synthetic fixtures for prototype parts

Assembled, color coded and inspected tooling for drilling operations: Turnkey products, exceeding your needs and expectations.

We can build both large and small:In our 30,000 square foot facility with 17 foot ceilings and full climate control, we can build all sizes of assembly tooling per customer supplied requests or designed in-house.

We are pleased to introduce our company, Liberty Tool, Inc. We design and build checking and assembly fixtures. We have been in business since 1995 with all principles having 20+ years experience in aerospace and automotive tooling. We presently have 15 toolmakers and continuously encouraging education to develop a well-rounded long-term partnership with our employees.

Prototype Bulkhead - 7050 Aluminum in Alodine and Prime 100" x 30" Footprint 5-axis CNC Machined. Simple to Complex: We can build but R&D and/or Production parts to the most stringent specification.

Top quality and beautifully finished tooling at competative pricing with short lead times: We can build to your design or utilize our in-house design services. Designs available in native Catia format. Wing Box transfer carts, trunion tools, AJ, FAJ, TOAC, HOFX tools are all manufactured in-house by our experienced personnel.

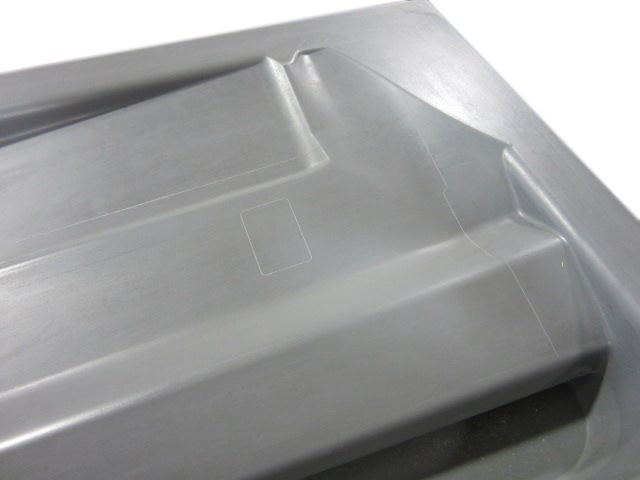

Kirksite Stretch Form Block W/Transfer Pinups Designed / Machined per the most stringent aerospace standards: Brilliant surface finishes performed in-house with multiple coating available.

Located in Sterling Heights, MI. our manufacturing area consists of 30,000 square feet. Our services include, design, build, and certification of aerospace tooling, checking fixtures, special machines, automate tooling and CNC machinging of parts and detail work.

High Temp. Fiberglass Composite Eggcrate Layup Mold: Dual Cavity tooling for high temperature laminations saving customer cycle times while lowering tooling cost.

OHME - Overhead moving equipment manufacture and proofloading: Assemblies manufactured to the most stringent specifications in the business. Class I welds proofloaded and inspected to meet or exceed customer requirements.

Specialty fixtures for all application for switch spring wires to airbag simulation. Let our design team create an inspection solution direct from GD&T to concept to final design. Catia, Unigraphics, 3D PDF and many other formats available.

Quality Policy: Liberty Tool, Inc. strives to establish long term business partnerships with our customers through a commitment to deliver quality products on-time while promoting customer satisfaction, compliance to all industry requirements and continual improvement in the effectiveness of our overall business processes. We are committed to continually improving our operations through investment in our employees, customers, suppliers and the overall quality management system.

Both Large and Small VACF: Machined per customer designs or designed internally. We can provide multiple vacuum chambers with base pin-ups for easy set-up and run.

Equipment Capabilities : • 1 Contract Faro Laser Tracker • 1 Portable Arm CMM: Master3D Gage 1.2 m (4 ft) Volume • 1 CMM: Wenzel LH87 32" x 27" x 39" Envelope • 1 CMM: POLI-GLOBO 1500 Horizontal - 120" x 60" x 60" Envelope • Various hand-held measureing devices Software Capabilities : • Verisurf X9 with Native Catia Import • MasterCam X9 • PC-Dmis • Capps6 • Rhino5 Our facilites include ... • All laboratory measuring equipment traceable National/International Standards(NIST/NPL) • 24 Hour Temperature-Controlled and Monitored Inspection Facility.

Fill out the supplier quality survey downloadable in the link below and return as instructed on the survey: Supplier Quality Survey

5 Axis Machining Centers : • 1 CNC Machine: HAAS VR-11 - 120 x 40 x 30 • 2 CNC Machine: HAAS UMC 750 - 30 x 20 x 20 3 Axis Machining Centers : • 2 CNC Machine: HAAS VF9 - 84 x 40 x 30 • 1 CNC Machine: HAAS VF6 - 64 x 32 x 30 • 1 CNC Machine: HAAS VF3 - 40 x 20 x 25 • 2 CNC Machine: HAAS VF2 - 30 x 20 x 20 CNC Lathe : • 1 CNC Lathe: HAAS ST10Y - Full Turning with 3 Axis Milling 3 Axis Fabrication Centers : • 1 CNC Plasma Cutter: Torch-Mate - 48 x 72 Manual Machinery: • 12 Vertical Mills with readouts • 2 Manual Lathe Machines • 3 Surface Grinders: Boyer Schultz • 1 Wet Grinder: Brown and Sharpe • 2 Welders: MIG & TIG • 4 Vertical cut off saws • 1 Horizontal cut off saw Our facilites include ... • 24 Hour Temperature-Controlled Manufacturing Facility.

0086-813-8127573

0086-813-8127573