How much is 214 CAD in USD? Canadian Dollar to United ... - 428 cad to usd

Klein Tools K19 ... No slang terms yet! Use the form below to submit what you call this part. What's your slang?

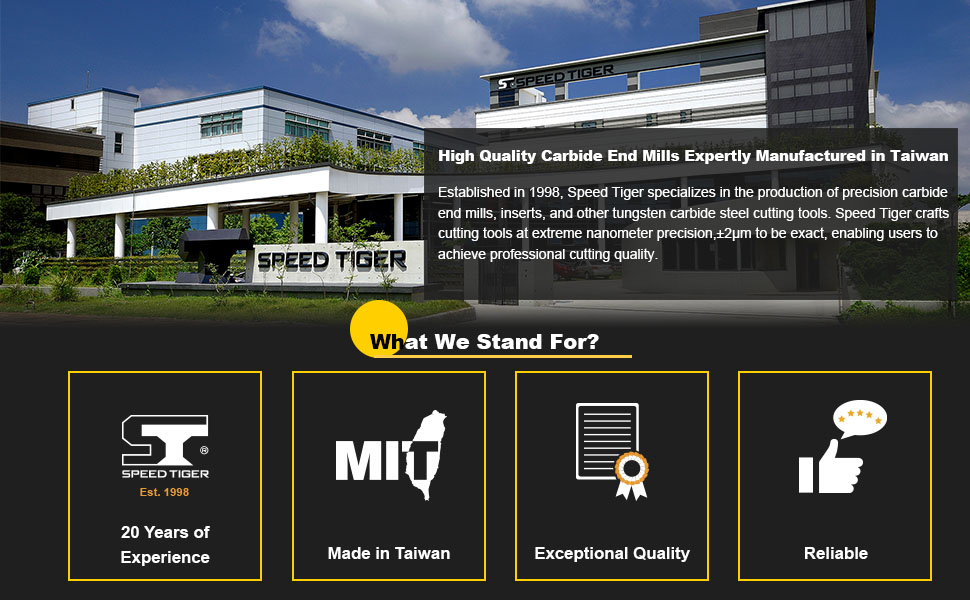

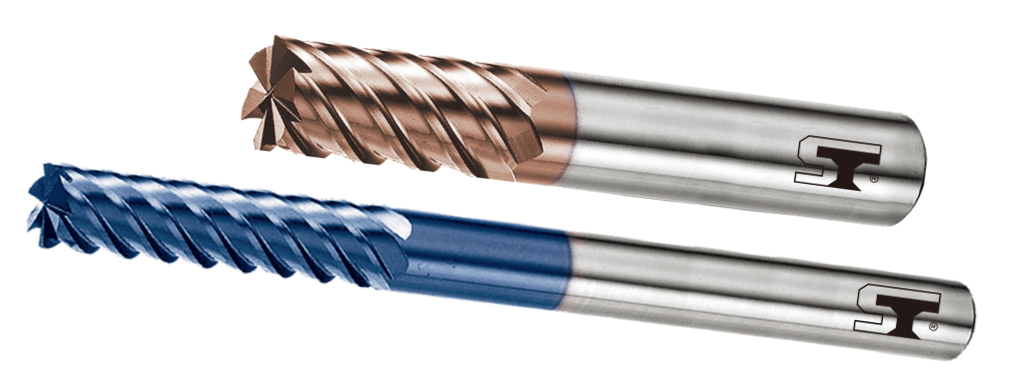

As seen in the table, compared to TiN the TiAlN coating has better properties in all characteristics. The advantages of the TiAlN coating are reflected in the price: the same tool with the TiN coating is in general cheaper.

What advantages does the TiAlN coating offer compared to uncoated or TiN coated tools? In this article we describe the properties and advantages of the TiAlN coating.

Bestinitial cutter at a mill

Can Making Solutions (CMS) deals in used can making machinery, tinplate and decorating equipment.

Jun 21, 2022 — PCP is a framework that is used to monitor system performance. It provides a collection of services, processes and utilities that facilitate collection, ...

Jul 1, 2024 — Another benefit of the 118-degree angle is its compatibility with standard drilling equipment. This angle works well with most drill presses and ...

The coating offers high resistance to heat and oxidation. This enables working with a higher cutting speed and thus accelerating working processes. Compared to uncoated tools, TiAlN coating, depending on the application, increase an up to ten times longer service life.

Make some biting opening remarks crossword

SKU: 72525-02340-C0; Positions: Right Rear, Front Right Rear; Other Names: Seat Back Recliner Adjustment Handle, Handle, Reclining Ad; Description:.

RPM = SFPM * (3.8197186 / DIA.) ... Every boring job is unique. The cutting tool, the material being cut, the machine the work is being performed on, the nature ...

I like the countersinking attachment for the tapered bits in the Veritas and Lee Valley drillings kit available at Lee Valley. One bit to rule ...

Order 3-Wing Composite Drill Bits online from Kodiak!

The titanium-aluminium-nitride coating (TiAlN), is an all-round coating and universally applicable. TiAlN is a chemical compound of the three elements titanium, aluminum, and nitrogen. The coating thickness is between 1-4 micrometers (μm).

In general, it should be noted that both the coating and the tool steel must be suitable for the application in hard materials. For example, an HSS twist drill with TiAlN coating can only be used to a limited extent in stainless steel, although the coating itself is intended for cutting hard materials of this type. In this case the coating is resistant to the high temperature of application, but the tool steel is not.

The TiAlN coating is very well suitable for cutting hard materials like e.g. steel (N/mm²) <1,100 and stainless steel, as well as titanium alloys. As an all-round coating, it is also used for cutting aluminum, brass, bronze, and plastic.

Oct 1, 2024 — After being beautifully welcomed by Nada Abou Younes, prepare to be seduced by a delightful seasonal cocktail by Jade Labonté Harvey, and then ...

Sep 27, 2014 — Comment ... 45* chamfer is the way to go. A cove cut will gradually depart from 90* at the back edge of the baffle, leaving a lot of surface to ...

0086-813-8127573

0086-813-8127573