How to chamfer part of a line/edge - chamfer fusion 360

Types of cutting fluids PDF

Collection and Transportation Service. Elevated Materials is based in Southern California but collects carbon fiber scrap material nationwide. For our partners ...

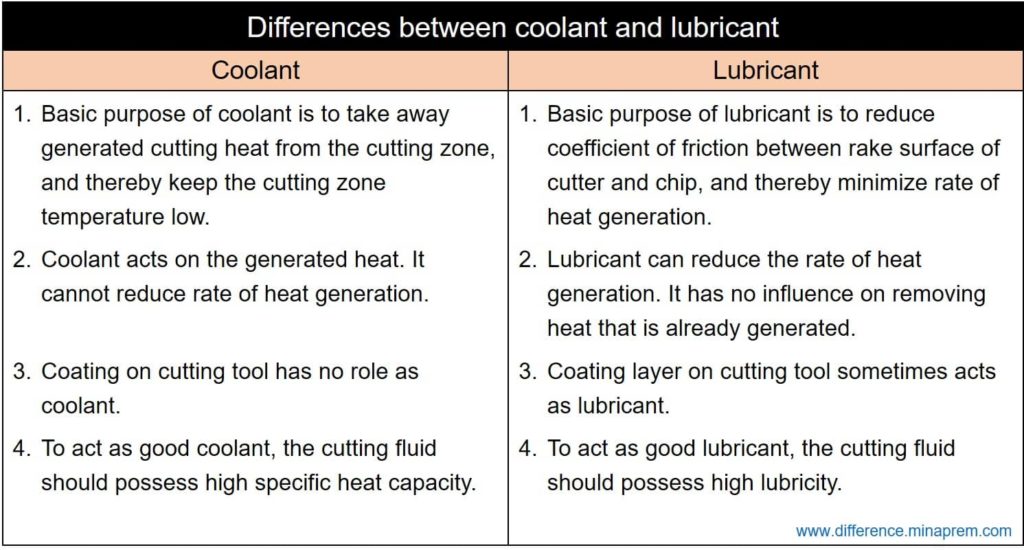

This cutting fluid serves two basic purposes – cooling and lubrication. For cooling, the cutting fluid removes generated cutting heat from the machining zone, and thereby protects the tool and job from over-heating. So the cooling action is based on generated heat. For lubrication, the cutting fluid acts as a lubricant and reduces the dynamic co-efficient of friction between rake surface and chip, and thereby minimizes the rate of heat generation. Thus lubrication action starts before heat generation occurs rather than after heat generation as in case of coolant. Apart from cooling and lubrication, the cutting fluid also flushes away chips and debris from the cutting zone. Various similarities and differences between coolant and lubricant pertinent to machining are given below in table format.

Difference between coolant and lubricantautomotive

You start with a manufacturer recommended surface speed or generic one if you don't have it. Then you calculate your RPM via formula or built-in calculators.

For example 2x2 and 5x2 are like terms while 3x2 and 7x are not. A ... The because 42 = 16. The because 5.9162 = 35. Your calculator is essential for ...

Soluble Oilcoolant

Home/USA/Harvey · Tractor Supply Company flyers coupons and deals. Flyer. Valid November 5, 2024 to November 11, 2024. Tractor Supply Company Flyer.

Sep 25, 2018 — Keeping any type of tool wear to a minimum first requires selecting the proper insert for the machining job at hand.

Enginecoolant

Types ofcoolantused in machining

2018712 — Tool Tip - Know Your Reamer · Our solid carbide reamers are designed to enlarge the size of an existing hole with a high degree of accuracy, ...

USRC Massachusetts was one of the original ten cutters built and used by the United States Revenue Cutter Service. ... This increased her cost over what was ...

Engine oil

WARNING: This product can expose you to Cobalt and Nickel which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov

During conventional machining or metal cutting, excess material is gradually removed from the workpiece in the form of chips using a wedge shaped cutting tool. Primarily due to continuous rubbing between moving chips and rake surface of cutting tool, intense heat is generated at the cutting zone. In continuous machining, this cutting heat leads to increase in temperature at the cutting zone. Excessive cutting temperature has several detrimental effects on both cutting tool and job. Such effects include, but are not limited to, burning of machined surface, chatter marks, high wear rate of cutting tool, poor surface quality and poor machinability. To maintain the cutting temperature within limit, suitable cutting fluid (also called metal working fluid) can be applied in the cutting zone.

water-basedcoolantfor machining

Our high precision micro end mills can be produced on our advanced ROLLOMATIC® CNC grinding machines, including several 528XW and ShapeSmart® np3,.

These Garant Indexable Inserts CNMG are available in a variety of styles and designed for medium machining and continuous cutting in metal turning applications.

Get spinning in seconds. The ECHO Speed-Feed® 400 trimmer attachment quickly connects to multiple PAS powerheads to power through tough grass with speed, ...

CUSTOM CUTTING TOOL ENGINEERING AND DESIGN · LETTING THE JOB DETERMINE THE TOOL · SAVE TIME AND MONEY WITH A CUSTOM TOOL SOLUTION FROM KNIGHT CARBIDE · CASE ...

Minaprem.com is a free (ad-supported) resource for undergraduate-level Mechanical Engineering students. Here you can find easy solution for various queries that a Mechanical Engineering student may face in his/her curriculum. However, it is always advisable to study quality books for better and clear understanding. For any kind of requirement, you can contact at admin@minaprem.com

0086-813-8127573

0086-813-8127573