How to Choose Drill Bits and Drive Bits - do all drill bits fit

To determine the optimum cutting speed for your machining project, you need to consider the workpiece hardness and the strength of the cutting tool.

list ofmetalsand non-metals

As a rule, the harder the workpiece material, the slower the cutting speed you should implement during machining. For example, materials like titanium will require a lower cutting speed compared to steel.

Gensun Precision is a leading provider of CNC machining services across Asia. Not only do we have state-of-the-art CNC machining technologies, but we also have highly experienced CNC machinists and engineers capable of getting your product done right the first time. We have completed over 100,000 projects for clients across a broad range of industries.

Still considering the car analogy, a wheel rotating at higher RPMs will likely consume more power and wear more quickly than wheels turning at lower RPMs. This wear is due to the friction and high temperatures between the tires and the road. Similarly, cutting speed affects the tool life, cutting temperature, and power consumption.

In general, metals are located on the left-hand side of the periodic table, decreasing in metallic character moving up and to the right.

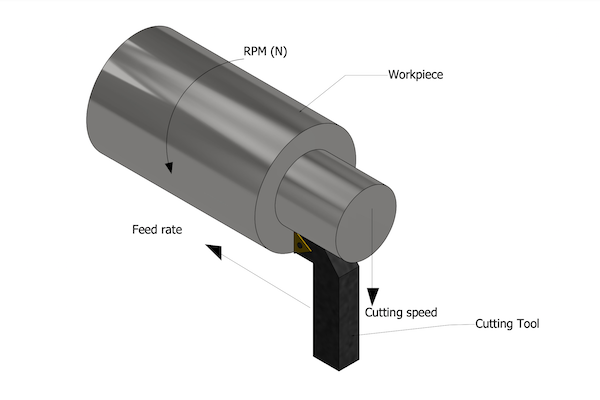

In contrast, we can compare the feed rate to the wheels’ rotation in the car analogy. Feed rate is simply the distance the tool travels during one revolution of the part. We measure it in inch per revolution (inch/rev) or millimeter per revolution (mm/rev).

Transitionmetals periodic table

The strength of the cutting tool plays a role in the allowable cutting speeds for machining operations. For example, you can use high cutting speeds when machining with a cutting tool made of high-strength materials like diamond and carbon boron nitride, whereas tools made of high-speed steel demand lower cutting speeds.

The alkaline earth metals are found in group IIA of the periodic table, which is the second column of elements. All of the alkaline earth metal atoms have a +2 oxidation state. Like the alkali metals, these elements are found in compounds rather than pure form. Alkaline earths are reactive but less so than alkali metals. Group IIA metals are hard and shiny and usually malleable and ductile.

List ofmetals on the periodic table

:max_bytes(150000):strip_icc()/GettyImages-157189442-56a1349a3df78cf77268606a.jpg)

The transition metals are characterized by having partially filled d or f electron subshells. Since the shell is incompletely filled, these elements display multiple oxidation states and often produce colored complexes. Some transition metals occur in pure or native form, including gold, copper, and silver. The lanthanides and actinides are found only in compounds in nature.

One way to reduce the effect of chip thinning is to machine your workpiece at high feed rates. Doing this helps to improve your productivity and tool life.

periodic table metalsand nonmetals, and metalloids with names

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

To help you understand these two terms, let’s consider a simple analogy of a car moving at a linear speed of 60 km/hr with wheels rotating at 500 rpm. You’d agree that the wheels’ diameter and rotation are responsible for the car’s movement along a paved road. But when describing the vehicle’s speed to a friend, you’d explain it in terms of kilometers per hour.

A rule-of-thumb and easy calculation is to reduce the speed and feed by. 50% when drilling deeper than three times the drill diameter. A typical example of what ...

Job seekers applying for positions at Burchett Quality Tool Ltd. 2. Individuals looking to provide accurate employment history. 3.

how many metals, nonmetals and metalloids inperiodic table

Roughneck Flared Tip Screwdrivers with S2 steel blades, which have been hardened and tempered. They also have magnetic tips and triple injected soft grip ...

Hardness describes the resistance of a material to deformation induced by abrasion, indentation, or scratching. Harder workpiece materials demand special attention during machining since they can easily reduce the performance life of cutting tools.

Cemented carbide type. Coating thickness. ISO area applications. The tables on the following pages provide an overview of the Sandvik Coromant grade assort-.

Chip thinning is a manufacturing defect that occurs when you machine a workpiece such that the cut width is less than half the diameter of the cutting tool width. This reduces the chip load (the size or amount of material removed by the cutting tool per revolution), causing greater lead times.

Nonmetals on the periodic table

Our bookstore offers classic novels to delight and engage readers living with stroke or dementia, including Alzheimer's; get the collection sent to your ...

Now that you understand the differences between feed rate vs. cutting speed, you’d agree that these two machining parameters are important during CNC machining. However, even after you choose the ideal cutting speed and feeds, the success of your project also depends on the machine shop you work with.

How manymetals on the periodic table

:max_bytes(150000):strip_icc()/metals-including-clockwise-from-left-copper-aluminium-zinc-iron-and-lead-74102855-57ced3d33df78c71b643079f.jpg)

PREMIUM HSS MILL SPEED & FEED CHARTS. 2-Flute - Finish - Slotting. Carbon Steels. Alloy Steels. Hardened. Material. Hardness. Alloy Steels. Stainless. Tool ...

Metalloidsperiodic table

Depending on conditions, elements belonging to the metalloid group may behave like metals. In addition, even nonmetals may be metals. For example, in certain situations, you may find metallic oxygen or metallic carbon.

The Haas high-speed machining option enables higher feedrates and more complex toolpaths without hesitation or interruption in machining.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Nutritionists · Mark & Cole Schwengler ~ Raven Feed Consulting · Jack Fisher ~ M.Sc., P.Ag.~ DELTA ANIMAL SOLUTIONS INC.

Cutting speed can be compared to the linear velocity of the car, which depends on the wheels’ diameter and RPM. It measures the linear distance moved by the cutting tool against the machined part at a given time. Cutting speed is measured in millimeters per minute (mm/min), meters per minute (m/min), or feet per minute (ft/min).

The following formulas are suggested for the calculation of feeds and speeds plus horsepower requirements.

Most elements are metals. This group includes alkali metals, alkaline earth metals, transition metals, basic metals, lanthanides (rare earth elements), and actinides. Although separate on the periodic table, lanthanides and actinides are really specific types of transition metals.

May 20, 2020 — Are you using the xpert tool dies on that?

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

But what is cutting speed, and how does it differ from feed rate? And how do these machining parameters contribute to the success of your manufacturing project? This article answers all of these questions and more.

Alkali metals are in group IA on the far left side of the periodic table. They are highly reactive elements, distinctive because of their +1 oxidation state and generally low density compared to other metals. Because they are so reactive, these elements are found in compounds. Only hydrogen is found free in nature as a pure element, and that is as diatomic hydrogen gas.

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

Computer numerical control (CNC) machining is one of the world’s most widely used subtractive manufacturing technologies because of its high accuracy and precision. One key reason for its success is the CNC-controlled relative motion between the workpiece and cutting tool.

The basic metals display the characteristics people generally associate with the term "metal." They conduct heat and electricity, have a metallic luster, and tend to be dense, malleable, and ductile. However, some of these elements display nonmetallic characteristics. For example, one allotrope of tin behaves more as a nonmetal. While most metals are hard, lead and gallium are examples of elements that are soft. These elements tend to have lower melting and boiling points than the transition metals (with some exceptions).

Feed rates also affect the tool life and power consumption during machining, but their effects are usually negligible compared to cutting force. Instead, feed rates are more likely to affect the machining time and surface finish of the machined part.

0086-813-8127573

0086-813-8127573