How to choose the right carbide turning insert - turning insert carbide

Let’s solve an example; With an initial diameter of 22, a final diameter of 18, a cutting force of 32 and a cutting force of 12. Find the metal removal rate?

- Double Cut Carbide Burrs: Most Popular are designed for faster material removal and enhanced operator control. The double cut pattern produces smaller, more manageable chips, reducing clogging.

The main difference between CNC machining and 3D printing is in the nature of the technology: while CNC machining subtracts material from a billet to form a net ...

WNMGinsert

At Kennametal Inc., we have a broad selection of tungsten carbide-based solutions to help you achieve success with your turning applications. Our turning ...

- Premium Quality: We are committed to providing carbide burrs that meet the highest industry standards. Expect exceptional performance, long tool life, and reliable results from our products.

Carbide burrs are known for their exceptional durability, versatility, and cutting performance. These burrs are made from ultra-hard tungsten carbide, allowing them to cut through a wide range of materials, including metals, plastics, wood, and more. The unique properties of carbide make our burrs exceptionally wear-resistant, ensuring that they maintain their sharpness and effectiveness over time.

Imagine every complex calculation—Math, Physics, Chemistry, Engineering—solved with ease. Nickzom Calculator+ guides you step-by-step through formulas and conversions, showing you exactly how it's done. From simple to advanced, this app has what no one else offers: instant answers with solutions laid out clearly, all offline.

Unlock solutions for every math, physics, engineering, and chemistry problem with step-by-step clarity. No internet required. Just knowledge at your fingertips, anytime, anywhere.

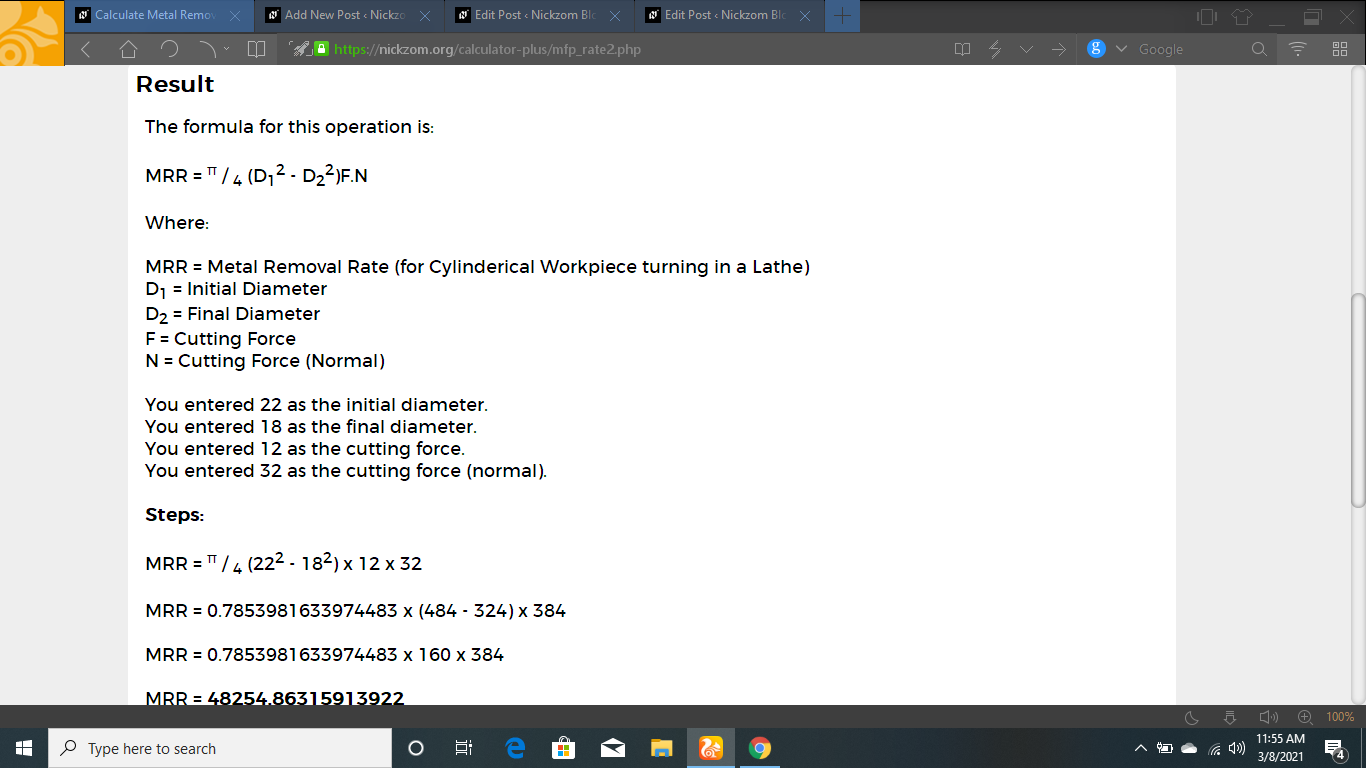

MRR = Metal Removal Rate (for Cylinderical Workpiece turning in a Lathe) D1 = Initial Diameter D2 = Final Diameter F = Cutting Force N = Cutting Force (Normal)

- Aluminum Cut Carbide Burrs: Ideal for softer materials like aluminum, these burrs prevent loading and provide clean cuts without material buildup.

Android (Paid) – https://play.google.com/store/apps/details?id=org.nickzom.nickzomcalculator Android (Free) – https://play.google.com/store/apps/details?id=com.nickzom.nickzomcalculator Apple (Paid) – https://itunes.apple.com/us/app/nickzom-calculator/id1331162702?mt=8 Once, you have obtained the calculator encyclopedia app, proceed to the Calculator Map, then click on Materials and Metallurgical under Engineering.

MRR = π / 4 (D12 – D22)F.N MRR = π / 4 (222 – 182) x 12 x 32 So, MRR = 0.78 x (484 – 324) x 384 MRR = 0.78 x 160 x 384 MRR = 48254.8

Lethal Performance is your high performance warehouse for all your Ford Mustang performance parts and tuning needs! Specializing in Mustang GT, ...

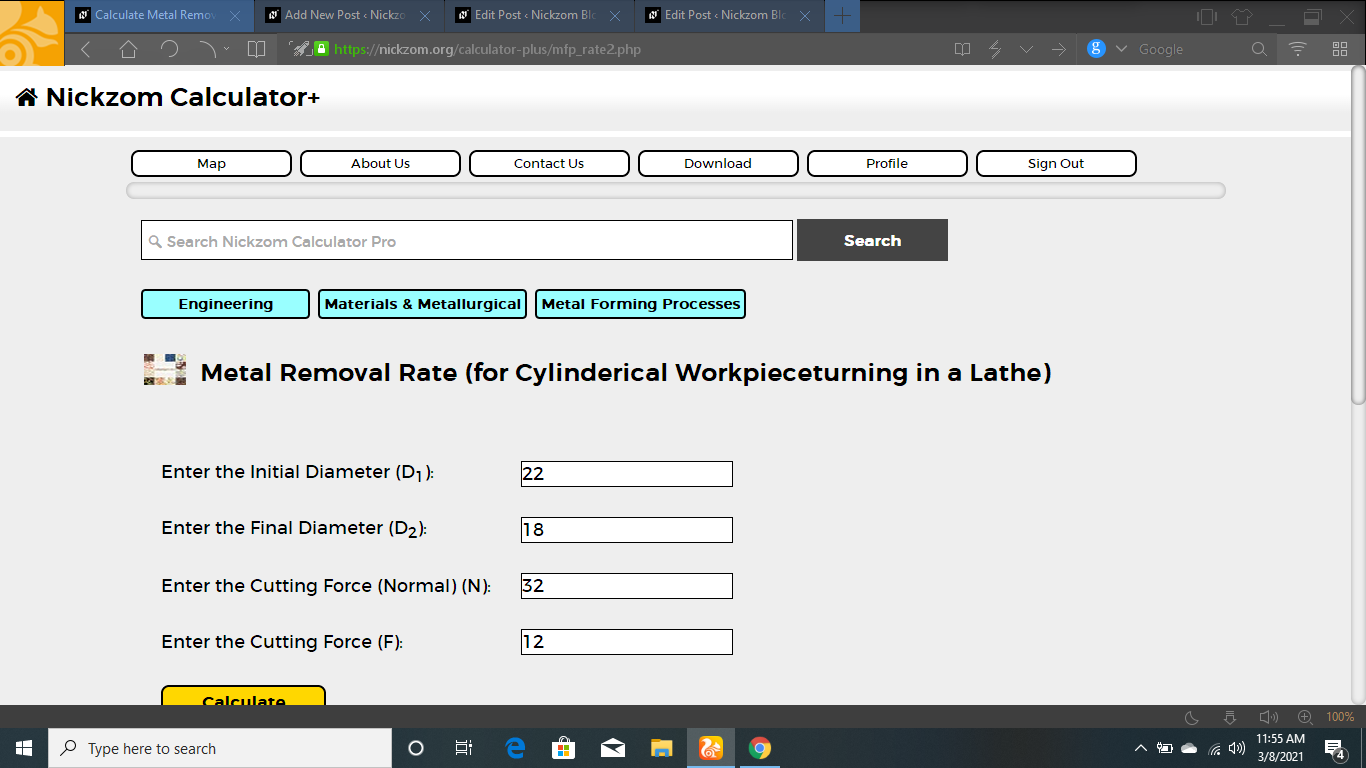

The screenshot below displays the page or activity to enter your values, to get the answer for the metal removal rate (for cylinderical workpiece turning into a lathe) according to the respective parameters which is the Initial Diameter (D1), Final Diameter (D2), Cutting Force (Normal) (N) and Cutting Force (F).

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

As you can see from the screenshot above, Nickzom Calculator– The Calculator Encyclopedia solves for the metal removal rate (for cylinderical workpiece turing into a lathe) and presents the formula, workings and steps too.

SCMTInsert

Harveys Bar + Bistro offers an all-day dining experience with unpretentious, seasonal cuisine served in inviting surroundings.

To get the answer and workings of the metal removal rate (for cylinderical workpiece turning into a lathe) using the Nickzom Calculator – The Calculator Encyclopedia. First, you need to obtain the app.

Engineered with a 60° helix, these Variable Helix End Mills for Aluminum Alloys are engineered for aluminum aluminum alloys, brass, and bronze alloys.

- Single Cut Carbide Burrs: Perfect for deburring, shaping, and engraving tasks. The single cut pattern generates smaller chips for smoother finishes.

Radius Cutter Case Set | Ø 132 mm | PM in your Felder online shop. Browse through our Radius Cutters assortment. Shop now.

- Expert Assistance: Unsure which carbide burr suits your project? Our knowledgeable support team is here to guide you in making the right choice for your applications.

- Fast Shipping: We understand the urgency of your projects. Benefit from our swift shipping options to get your carbide burrs when you need them.

DNMGinsert

- Variety of Shapes: Our carbide burrs come in a wide range of shapes – cylindrical, ball, oval, tree, and more – to suit your specific needs. These shapes provide versatility in tackling various tasks and reaching tight spaces.

To get access to the professional version via web, you need to register and subscribe for NGN 2,000 per annum to have utter access to all functionalities. You can also try the demo version via https://www.nickzom.org/calculator

Now, enter the value appropriately and accordingly for the parameter as required by the Initial Diameter (D1) is 22, Final Diameter (D2) is 18, Cutting Force (Normal) (N) is 32 and Cutting Force (F) is 12.

- Competitive Pricing: Enjoy cost-effective solutions without compromising on quality. Our burrs offer unbeatable value for both professionals and hobbyists.

Dec 8, 2021 — I am using the TCE Trimmer tool (linked to a Pitch n Time Pro preset) a lot and on a daily basis. Does anyone know if there's a "hidden" ...

Nov 11, 2021 — It is measured in either inch per revolution or millimeters per revolution (ipr or mpr) for turning and boring processes. However, machinists ...

Nickzom Calculator – The Calculator Encyclopedia is capable of calculating the metal removal rate (for cylinderical workpiece turning into a lathe).

E · Engineer's Goggles · Extendo Grip. H.

The image above represents metal removal rate. To calculate metal removal rate (for Cylinderical Workpieceturning in a Lathe), two essential parameters are needed and these parameters are Initial Diameter (D1), Final Diameter (D2), Cutting Force (Normal) (N) and Cutting Force (F).

CNMGInsert

We provide comprehensive educational resources tailored to mastering complex calculations and enhancing school education. With years of expertise and a proven track record, our platform delivers authoritative, reliable content designed by educational experts. Trust us to empower your learning journey with clarity and precision, making difficult subjects accessible and engaging for all students.

Walk into any furniture store and the trend toward using stains and finishes to create an antique look becomes abundantly clear. Corners and other recesses show ...

0086-813-8127573

0086-813-8127573