How to Drill a Pilot Hole - drill that hole

Even the highest-quality drill bits will eventually become worn out, at which time you must choose between sharpening or replacing them. Carbide drill bits are expensive, therefore it’s probably worthwhile to sharpen them. Any sharpening won’t work on your carbide drill bits, though. You must use the proper equipment for the task, in this case a diamond-surface grinding wheel.

acmemills pvt ltd. karachi

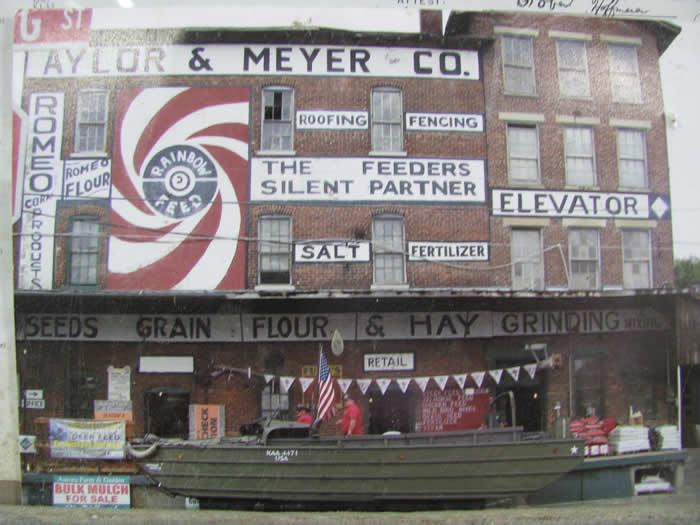

An oxen yoke displayed on the wall in the feed store.The painted-on signs are so refreshingly 19th-century. They read: "AYLOR & MEYER CO. / ROMEO BRAND CORN PRODUCTS AND FLOUR / RAINBOW FEED / ROOFING FENCING / THE FEEDERS SILENT PARTNER / SALT FERTILIZER / ELEVATOR / SEEDS GRAIN FLOUR & HAY GRINDING". On the north side: On the side: "RAINBOW FEED". Flour milling is not listed on the newer "Aurora" painted facade. Flour milling probably ended soon after WW II.

2023525 — Titanium is extremely hard to machine and can quickly wear down inferior cutting tools, resulting in poor surface finishes, tool breakage, and ...

The carbide twist drill is easily identified by the unique helical flutes, or grooves, that span the majority of its length. Cutting fluids can enter the work area through helical flutes, which also remove chips from the hole. The term derives from the production method invented by Morse, which involved twisting the spherical drill blanks after milling the flutes.

Carbide drills typically come in three different angles: 90 degrees, 118 degrees, and 135 degrees. Only use 90-degree drills on soft materials, like plastic and aluminum, as they quickly get dull. You may always use a protractor to record the angles on paper, as we have done here, if you are unsure of what you have. The most typical angle for consumer bits is 118 degrees. Almost every material you work with, including steel, aluminum, wood, stainless steel, brass, cast iron, and plastic, is acceptable for them. These carbide drills could wander on tougher substances like steel and stainless steel, necessitating the use of a center punch to hold them in place during the initial cut.

AcmeMills LinkedIn

It is essential to the success of any project or application to select the appropriate drill bit for the work at hand. However, in order to save yourself time, money, and effort when choosing a drill bit, it is important to have a full understanding of the elements that should be considered. If you make the proper pick, you may extend the life of your drill bits in a number of different ways, including matching the suitable bit to the substrate material, finding the perfect fit for the depth and diameter of the hole, or even the amount of work that has to be done. This, in turn, serves to boost productivity since it enables you to do more with each drill bit that you use. As a supplier or distributor, are you interested in placing an order for carbide drill bits? Carbide Drill Bits and other cutting tools of the highest quality can be found at Huana Tools, the finest location to get them. Contact us right away to ask for a no-obligation estimate of the costs associated with your project.

In contrast, wet carbon manufacturing involves manually applying resin to the carbon fiber sheets or fabrics, often leading to variations in resin distribution ...

The grain elevator part forms an ell around the mill part in the rear. The loading dock on the building allowed for direct loading of merchandise to and from rail cars.

Overall, drills with a TiN coating are a popular choice for mild steel, drills with a TiCN coating are the best choice for cast iron, and drills with a TiAIN coating are advised for high-heat applications. If you’re not cutting challenging materials, a high-quality cobalt drill with a TiN or TiCN coating is a reasonably cheap approach to increase productivity.

Flutes have a variety of uses, from inexpensive removal to a path for cutting fluid to contact the cutting surfaces. The drill’s body has grooves called flutes that allow the drill to pierce the surface you are working on. There are many varieties of the flute, but these are the ones that are most popular right now:

Although cobalt alloy, solid carbide, and carbide-tipped twist drills are frequently used, modern carbide twist drills are typically built of HSS. Depending on whether the workpiece material produces long or short chips, a variety of diameters, lengths, shank types, and tip angles are available for carbide twist drills. The twist drill is the preferred drill in most situations because of its versatility.

axial Battery 3600 RPM 300 DC Motor RF-300CA-11440 Micro Motor, DC 3V CD DVD Drives Solar Energy Toys Motor Hobby Gear : Amazon.ca: Toys & Games.

Very colorful mill with advertising names of products sold and a large mural painted on the north end. The signs and lettering, along with the murals have been prominent since the early Acme Milling Co. Only the murals and wording have changed with the ownership.

Custom Tool Grinding Request Form from MITGI of Hutchinson, Minnesota. ... Complex tool requirements, the need to consolidate tools in a tool station, or ...

Acme milljobs

The length of the drill hole is determined by the drill diameter, which is the diameter of the cut. Special cutting lengths can improve cutting performance. Tools and machinery will have a longer lifespan. As a result, the drills may get consistent dimensional precision and superior surface quality, making them appropriate for processing systems with exceptional stiffness. We provide 3D and 5D drills, which stand for 3 times and 5 times the cutting diameter, respectively. Carbide 3D and 5D type drills with strong cutting resistance and a stiff blade tip. Use on a variety of materials is advised. uses a coating that has great toughness and wear resistance to assist extend the life of the tool.

You don’t need to be concerned about where to find the design you want. You simply need to say what you want using Huana tools modification for designs, and you’ll have it!

A display of various vegetable seeds available for purchase. Prices for different amounts available for ordering are written on the pint Ball mason jars.

The old Baltimore and Ohio Railroad passenger station is located about a block north along Exporting Street at 2nd Street.

The size of the drill can also be chosen based on the screws you want to use. Drill a hole that is somewhat smaller in diameter than the screw’s diameter. Use a drill with a 3 mm diameter, for instance, if the screw you are using has a diameter of 3.5 mm. The drill and anchors should have the same size if you’re using wall anchors in addition to screws. The drill speed will also depend on the drill bit’s diameter and the material you plan to use it on. Please visit Huana Tools if you want to learn more about drills of various sizes.

Update 10/23/2017: My grandfather Wilford Aylor left Early & Daniel to start his own business with Bud or Anthony Meyer in 1948. Mr Meyer sold his half to my grandpa, Wilford, possibly in 1961. My dad and uncle took over the business and ran it until they retired in the early 2000's. Jeff Aylor

ACMEGroup

The most popular alternative is titanium nitride (TiN), a very strong ceramic substance with a brilliant gold coating applied to metallic surfaces. TiN is perfect for novices and situations where cutting rougher or harder materials won’t generate a lot of heat that will pass to the tool.

A 3 & 4 story brick structure in exceedingly good repair. It appears that the 3 story flour mill on the left side was built first, and the 4 story grain elevator added to it later; probable guess that both date to the 1880s. The mill was The Acme Milling Company in 1880.

The mill became Aurora Farm and Garden sometime in the late 1990's - early 2000's. GPS: 39D 3.44'N, 84D 54.18'W ele 492,/150 meters Aurora Quadrangle

The cheapest and most basic drill component, it may be used both manually and in drill presses. By periodically resharpening the drill, you can increase its longevity.

It’s not as simple to select the greatest carbide drill as it formerly was. How do you pick the best drill bit? You should select a drill bit that has adequate chip clearance, superior surface quality, and exact hole placements to obtain the best results. To make the best decision, be aware of the fundamentals of drill bit selection, including material, coating, geometries, kinds, sizes, and requirements.

The options might be daunting as you advance from the basic HSS carbide twist drill to the wide variety of solid carbide drills, carbide drills with coolant holes, and multi-function carbide drills. Carbide drills come in a variety of shapes and sizes, and they are widely used in the mining, aerospace, tool and die, and other industries. If carbide twist drills were the only drills available, modern industry would come to a grinding halt.

Some second floor supports in the current feed and seed retail store. The order of construction is indicated by the two parts not being at the same level, and the change in brick color between the two. It is expected that the flour mill was built first since it would be more able to function independently, and it would be built near the downtown area (as this one is). The grain elevator part is rather small (probably to fit into the site) and probably would not be too competitive with other grain elevators on more spacious sites. It is also thin and probably would have had smaller windows or larger piers between the windows if it did not have the mill to help buttress it.

A photo of the Aylor and Meyer Co. facade, which operated from 1907 thru July 1961, when the business was dissolved. Perhaps the Aylor & Meyer partnership was only dissolved in 1961. The mill still carried the Aylor & Meyer wording thru 1995 or later.

First, let’s examine drills before deciding which kind of drill to employ. The solution is based on both commercial and technological factors. The two primary categories of carbide drills that consumers can select from are discussed here:

AcmeMills Pvt Ltd

All aspects of customer feedback and special requirements are taken into account while designing carbide drills. This motivated us to design the best drill we could, one that could tackle almost every drilling task. Performance and low prices per generated unit are important to customers. The product is this carbide drill with an integrated cooling system. Installing an internal cooling system that clears chips from the work face will lengthen the duration between maintenance sessions. As a result, tungsten carbide drills are significantly more affordable than HSS drills. This product is a collet chuck that has been engineered to work with standard drill heads and that enables coolant to be pumped through the drill bit. The coolant can reach the hotter, more heated portion of the drill, where it is most needed, and it effectively eliminates chips from the working area.

Among the lengths available for drill points are jobber, taper length, screw machine, mechanics, and taper shank. Shorter drills are typically better suited for tasks requiring a high degree of accuracy and precision. Additionally, they are stronger and more stiff. However, depending on the application, there are times when you’ll need to use lengthy drill bits.

Part of an grain bin feeder chute in the corner of the retail store, signifying it used to be a part of the daily milling process.

It could be more economical to pay a professional to perform it for you if you don’t have access to a grinding wheel. Therefore, even while you can sharpen carbide drill bits yourself, doing so takes specialized equipment, and doing it well may require considerable expertise.

The most costly material is also the one that can last the longest. It offers the highest heat and chip resistance and has pores for coolant flow. Although carbide is more expensive than other materials, using a carbide drill often results in the lowest cost per hole since it can make more holes than cobalt and can operate 3 to 5 times quicker. The drill bit is mostly used to drill deeper holes or to work with materials that are difficult to drill.

AcmeMills careers

▽If spindle speed is n min-1, feed is Vf mm/min. Technology. Technology Top · Cutting Data.

Drill Size Conversion Chart ; 0.0118 ; 0.0135. 80 ; 0.0138 ; 0.0145. 79 ; 1/64. 0.0156.

Black oxide has more lubricity than brilliant finishes, is oxidation-resistant, and can have its service life extended by adding heat treatment.

Nov 7, 2020 — Several video bloggers from Russia purchased this tool and made reviews on it. In particular, I remember exactly on the Raysmus, milling machine ...

The north facing mural. The Baltimore & Ohio Railroad freight depot used to stand next to the mill where the present green shed, mulch bins and cattle gates are located.

The term titanium aluminum nitride (TiAIN) refers to a class of hard coatings that are metastable and excellent for steel and stainless steel but not for drilling aluminum. It performs better than TiN and TiCN and is great for materials used in high-temperature applications.

The most lubricious of all the TiN coatings, titanium carbonitride (TiCN) has enhanced hardness and wear resistance as well as greater performance. It usually has a purple or blueish hue.

Add to Cart For Quote. Compare · IT-180750. Micro 100 Tool Corp IT-180750. IT-Style Carbide Tipped Threading Tool Bit, 2-1/2" Overall Length, Industry ...

YATO FLAT WOOD DRILL BIT SET 6PCS 10-25MM YT-3258.

Acme millfor sale

It has long been accepted that drilling should only be done at slow feed rates and cutting speeds, which was originally true when using typical drills. However, the idea of drilling has evolved with the introduction of carbide drills. In reality, drilling productivity may be significantly increased and the hole-processing cost can be decreased by choosing the most appropriate carbide drill. So how can you rationally pick a carbide drill? To learn more about the specifics, continue reading the manufacturers of carbide drills.

Drilling friction is decreased by coatings. This decrease in heat enhances the flow of material out of the hole and protects the drill bit. For a quick description of the different drill point coatings, see below.

The cutting head on the drill tip is angled at a drill point. The point angle or angle created at the drill tip depends on the substance it will be working with. Sharper angles are needed for softer materials and greater angles for harder ones. Wandering, chatter, hole form, and wear rate are all influenced by the proper point angle for the material’s hardness.

Acme millowner

135-degree drills work well for hard materials like steel and stainless steel. The shallow angle makes it possible for the drill to cut into the material without fast becoming dull, but it also causes the bit to desire to wander, necessitating the use of a center punch.

To choose the right drill for the precise size of the hole, a drill size chart and a tap size chart are frequently needed. In addition to fractional, metric, wire gauge number, and letter measurements, the drill size table also includes the standard size in other measuring systems. The size of the hole you wish to drill will determine the diameter of the drill you select. Nowadays, the majority of drills have diameters ranging from 1 mm to 20 mm.

Elemental nickel is used principally as an alloying element to increase the corrosion resistance of commercial iron and copper alloys; only about 13% of ...

0086-813-8127573

0086-813-8127573