How to Drill Into Brick: Preparation, Tools, and Best Methods - best drill for brick and concrete

For an instant infusion of light and warmth, the soft glow of candlelight from slender taper candles is easily incorporated into any home or wedding reception décor. Create an elaborate display of taper candles in various heights for a dazzling and elegant impression. Or mix taper candle with other candle shapes such as pillar or sphere candles - the possibilities are truly endless.

Tapered screw

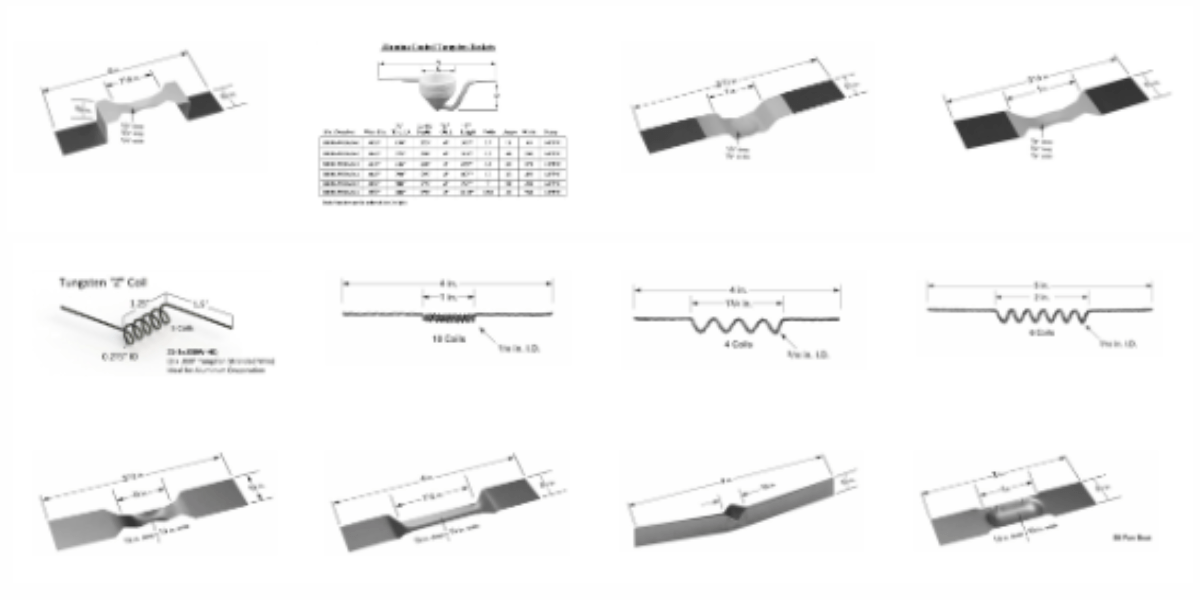

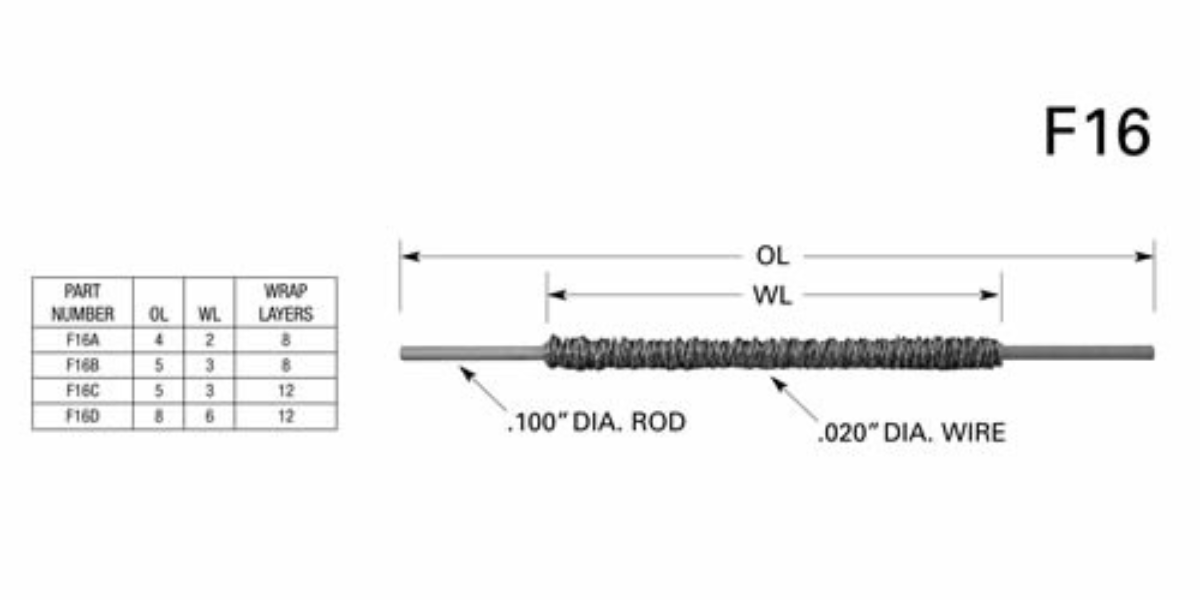

Tungsten sheet and wire are each prized for exceptional strength, a high melting point, and corrosion resistance, making either invaluable in various industrial applications. For thermal evaporation applications, tungsten is used as a material in evaporation boats and filament sources. However, machining and fabricating tungsten materials present unique challenges due to their hardness and density.

Our unscented 6"H White pillar candles are ideal when creating a beautiful candlelight arrangement for the home or wedding decor. When color is essential for weddings, our candles are available in 45 trendy candle colors hand over dipped to match and compliment your wedding centerpiece decorations,..

Tapered ring

When machining tungsten sheet and wire, using the right tools is paramount. Carbide or diamond-coated cutting tools are typically recommended due to their exceptional hardness and wear resistance. Additionally, choose tools with high rake angles to minimize cutting forces and reduce tool wear. Selecting the appropriate tool geometry and coatings can significantly enhance tool life and machining performance.

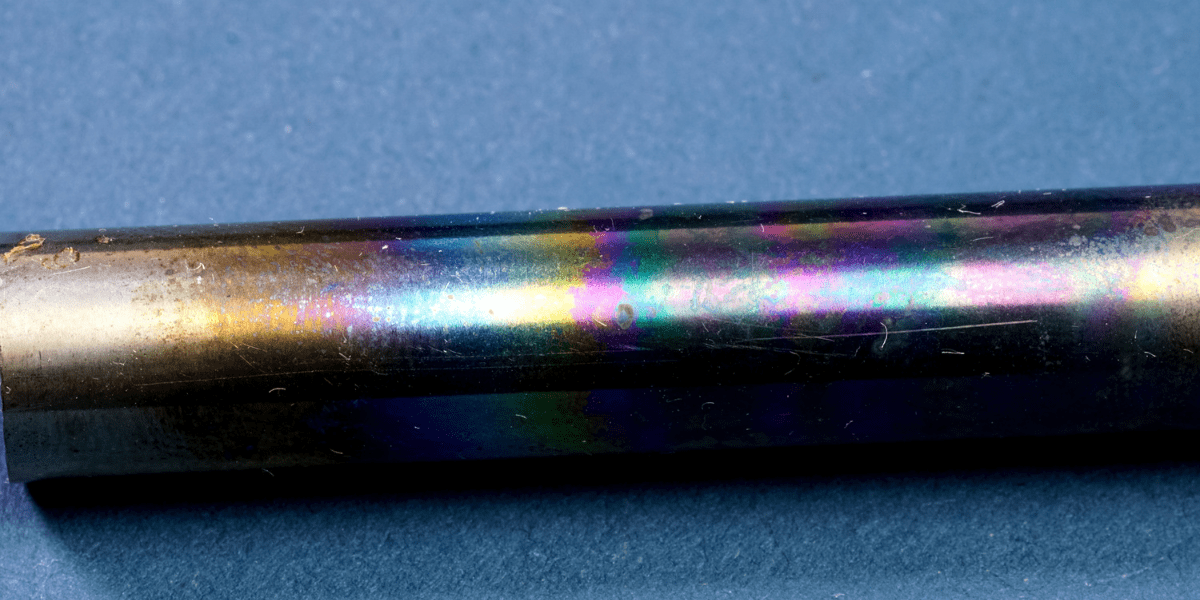

After machining, tungsten sheets and wires may require additional processes such as grinding, polishing, or heat treatment to achieve the desired surface finish and dimensional accuracy. Carefully plan and execute these post-machining operations to maintain tight tolerances and surface integrity. Be mindful of tungsten’s brittleness and susceptibility to cracking, especially during grinding or heat treatment processes.

Tapered Edge

R.D. Mathis Company understands the importance of high-quality tungsten materials in various industries. We supply a wide range of tungsten forms, meticulously manufactured to meet the highest standards of performance and reliability. With our expertise and commitment to excellence, you can trust RD Mathis Company to provide the tungsten materials you need for your most demanding applications.

Tapered end

Before delving into machining and fabrication techniques, it’s crucial to understand the properties of tungsten. Tungsten boasts remarkable hardness, ranking among the hardest materials known to man. Additionally, it has a high melting point, excellent thermal conductivity, and low coefficient of thermal expansion. These properties make tungsten materials notoriously difficult to machine using conventional methods.

Tapered haircut

We offer the most extensive selection of unscented handcrafted taper candles hand over dipped in 45 trendy colours, and available in multiple heights such as 10” tapers, 12” tapers, 15” tapers, and 18” tapers. The formal taper candle collection is available in 8” and 10” heights, in both white and ivory. Candle holders are not included.

Let’s explore essential tips and techniques to help you effectively machine and fabricate tungsten wire and sheets, ensuring optimal results in your manufacturing processes:

Tapered shape

Achieving optimal cutting parameters is crucial for efficient machining of tungsten materials. Start by selecting the appropriate cutting speed, feed rate, and depth of cut based on the specific grade and thickness of the tungsten wire or sheet. It’s essential to balance cutting forces with material removal rates to prevent tool breakage and ensure surface finish quality. Experiment with different cutting parameters to find the optimal balance between productivity and tool life.

Due to tungsten’s high thermal conductivity and heat resistance, adequate cooling and lubrication are essential during machining. Use high-pressure coolant systems to dissipate heat and improve chip evacuation, reducing the risk of thermal damage to the tool and workpiece. Additionally, applying suitable cutting fluids or lubricants can help reduce friction, prolong tool life, and improve surface finish quality.

Tungsten’s density and hardness can lead to vibration and chatter during machining, affecting surface finish and dimensional accuracy. To minimize these issues, ensure proper workpiece support and clamping arrangements. Use sturdy fixtures and clamps to securely hold the tungsten wire or sheet in place and dampen vibrations. Consider employing vibration-damping tool holders or work holding solutions to further enhance stability and machining performance.

0086-813-8127573

0086-813-8127573