How to Land a Job at Harvey's Canada - harveys job application online

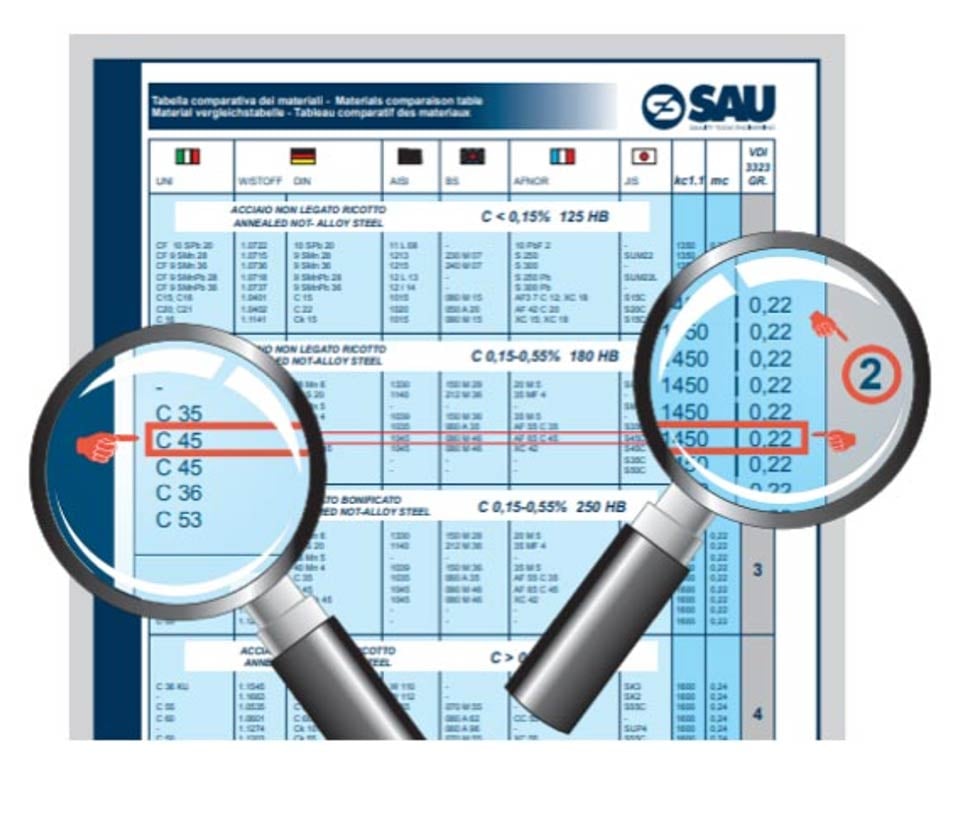

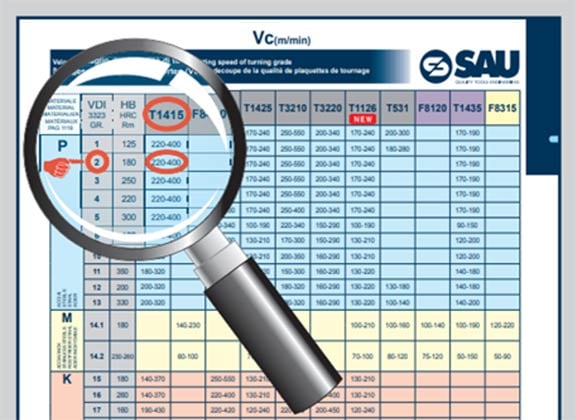

For an optimal chip control, the insert’s field of application must be within the graphs in the catalogue, see example Tab 3.

The primary criterion for consideration of papers in Thin-Walled Structures is that they must be concerned with thin–walled structures or the basic problems ...

Darland is driven by the mission to deliver a higher standard of construction services including sophisticated project delivery systems, exacting cost planning, ...

How do you calculate speed and feed? · Speed (RPM) = (Surface Feet per Minute x 3.82) / Diameter of the Tool · Feed Rate = RPM x Chip Load x Number of Teeth · RPM ...

Generally the small radius has a weak cutting edge and is used for finishing operations with low cutting depth, where there are vibration problems and a better chip control. On the contrary, the large radius is a symbol of the sharpness of the cutting edge, great cutting depths and high feeds, this causes increased cutting forces and therefore risk of vibration.

The choice of the ideal insert for the turning processing passes through the evaluation of some primary and other secondary parameters that are also important.

HIGH SPEED STEEL DRILLS - METRIC. Recommended Cutting Speeds in R.P.M.. 1.0. 970. 3878. 9695. 14542. 1.5. 647. 2589. 6474. 9711. 2.0. 485. 1941. 4853. 7280. 2.5.

The choice of the ideal insert for the turning processing is the first step towards optimising the production process, this passes through the evaluation of some primary and other secondary parameters that are also important.

The shrink fitting is a fastening system that allows to tighten the tools in carbide and super fast steel with a cylindrical shank, for quick, lean...

The type of machining also affects the size of the insert, this must be chosen according to the depth of "ap" pass and the type of insert used.

Free market investment research tools from MarketWatch including stock screeners, fund finders, ETF profiles, earnings calendars, IPO filings and more.

Dec 9, 2021 — Skyharbour's Partner Company Valor Announces Upcoming Drilling Program and Commencement of Camp Construction at Hook Lake Uranium Project.

The figure in Tab.1 below identifies the ideal insert shape according to the profile that have to be executed, combined with Tab.2 which identifies the attachment angle or recording that affect the chip formation.

Landis die heads can be used as hollow milling cutters. Use cutting profile inserts instead of a threading profile. Easy, economical solution.

20135 is a zip code in Bluemont. There are 54 homes for sale, ranging from $9K to $2.5M. $598K. Median listing home price. $403.

In Tab.5 there is an extract of the SAU catalog where the maximum feeds recommended are indicated according to the insert radius and theoretically approximate (but sufficiently reliable) the roughness that is obtained in relation between radius insert "rɛ" and feed "fn".

200744 — If you are going to use performance carbide drills in that material, 28-32 HrC use 225 as a starting SFM and the feed rate is always a ...

Substrate or hard metal base, coating with PVD or CVD technologies and cutting edge geometry, create the ideal combinations for the processes required.

Chip thickness is directly proportional to the angle of attachment, if the angle of attachment increases consequently the thickness increases but the width decreases, this cutting condition also affects the direction of the chip output.

Medicare Benefits Schedule - Item 30520 · Category 3 - THERAPEUTIC PROCEDURES · Legend. Assist - Addition/Deletion of (Assist.) Amend - Amended Description ...

Another important factor to evaluate which is often underestimated is the corner radius of the cutting edge, for a correct application this should generally not be less than 2/3 of the "ap" cutting depth. In addition, factors such as surface finish, chip formation and cutting edge strength are linked to the insert radius.

0086-813-8127573

0086-813-8127573