How to Open and Close a Tactical Knife - how to close a box cutter

OD grinding is used to shape the external surface of objects between the centers and excels at removing circular defects and restoring or creating roundness.

In fact, just about any material can be used with precision CNC metal machining — of course, depending on the application and its requirements.

Some metals that are commonly machined include aluminum, brass, bronze, copper, steel, titanium, and zinc. In addition, wood, foam, fiberglass, and plastics such as polypropylene can also be machined.

Today, CNC is a built-in feature of a wide range of equipment, from lathes, mills, and routers to wire EDM (electrical discharge machining), laser, and plasma cutting machines. In addition to automating the machining process and enhancing precision, CNC eliminates manual tasks and frees machinists to oversee multiple machines running at the same time.

So, with little or no deflection in its machining process, the CNC Swiss-style screw machine provides greater accuracy, precision, and consistency. Learn more about the advantages of eliminating deflection in our blog Deflection and Precision in CNC Swiss Machining.

To avoid the challenges of verifying OD/ID concentricity, try to use other applicable GD&T symbols in place of concentricity in tubing drawings and designs.

Surface finish requirements are among the details that are critical to creating a complete RFQ that will help to optimize for manufacturability.

The ability to Swiss machine a wide range of materials, including plastics as well as exotic metals and alloys, adds to the benefit of its use for the fabrication of medical device components.

Polygon machining is an operation used to create different geometric shapes on a part. It is a milling method that can be used to create a particular shape to mate with or tighten a threaded part.

Learn some common myths about plastic and reasons why it may not be a better choice than metal tubing for medical device applications.

The modern precision machine shop leverages CNC Swiss-style machining with a wide range of tools to create parts with an interesting array of features and functions, described below.

The process of machining small parts removes material and uses a wide range of cutting tools to create the final, and often highly complex, design of a part. The level of precision is enhanced through the use of computer numerical control (CNC), which is used to automate the control of the machining tools.

With a CNC lathe, a blank bar of stock material is loaded into the chuck of the lathe’s spindle. This chuck holds the workpiece in place while the spindle rotates. When the spindle reaches the required speed, a stationary cutting tool is brought into contact with the workpiece to remove material and achieve the correct geometry.

CNC mills are built for repeatability and can be used for everything from prototyping to high volume production. High-end precision CNC mills are often used for tight tolerance work such as milling fine dies and molds.

It’s critical to choose a supplier you can envision working with for the long haul. Review these practical guidelines to make the right decision.

For some medical device applications requiring biomaterials, tungsten and gold-plated tungsten wire may be suitable alternatives to precious metals such as gold.

Consider the methods used for heat treating metals, as well as the effects, when specifying your requirements for the cut-off of small metal parts.

Learn about the role that tight tolerance plays in optimizing for manufacturability, and how to specify tolerances to ensure part quality and control costs.

Pull rings for medical devices can be cut from 304 grade stainless steel tube or Swiss machined to provide specialty features and use other materials.

A horizontal mill is often used when a better surface finish is required; that’s because the orientation of the spindle means the cutting chips naturally fall away and are easily removed. (As an added benefit, efficient chip removal helps to increase tool life.)

An important characteristic of milling is that the workpiece remains stationary while the cutting tool spins. In other words, on a mill, the rotating cutting tool moves around the workpiece, which remains fixed in place on a bed.

Eddy current testing is an important method of nondestructive testing. See what you may not have known about the process.

When measuring the perpendicularity of small metal parts, consider the effects of a part’s diameter, length, straightness, and manufacturing method.

The centerless grinding process is ideal for finishing small cylindrical metal parts that require a tight tolerance and high-volume production. Learn some of the fundamentals of this process.

Learn more about Metal Cutting’s certification in the ISO 9001:2015 standards and commitment to quality management practices.

Any surface will have flaws under the right magnification. In this video we explain the inherent challenges with blanket requests and how to overcome them.

As you would expect, bone screws are cylindrical in shape with a head and thread along the length of the body. They can also have features such as holes and steps, as well as different tips designed to aid in adhesion of the anchor to bone or other tissue. The form and features of the anchors make CNC Swiss machining the preferred method for achieving the proper head, length, diameter, pitch, and tip.

Boring is anything but boring. It is actually a pretty remarkable technique, where you take an existing hole and expand it to a new, larger, precise diameter.

How do you qualify a new sourcing partner and ensure an efficient and problem free experience? Considering these points will help you make a decision you can feel confident about.

Most CNC Swiss lathes use one or two main spindles plus one or two back (or secondary) spindles, with rotary transfer responsible for the former. The main spindle performs the primary machining operation, with the help of a guide bushing.

Learn why the characteristics of titanium tube make it a good choice for medical devices and other applications that require strength, light weight, and corrosion resistance.

Learn why infiltration, density, and other properties of an alloy such as copper tungsten are important to the quality of spot welding electrodes.

In the case of a bolt — unlike a screw, where the motion is transmitted on the internal portion of the screw head — polygon machining meets the need for an external shape with a dedicated mating wrench to expert a rotational force. In addition, polygon machining could be used to create a mating part that is an integral part of an assembly.

For the purposes of precision CNC Swiss machining, a thread is a symmetrical radial feature that varies in its pitch. The pitch, or angle, determines the depth of the thread.

While CNC milling can deliver quick turnaround, as-milled finishing creates parts with visible tool marks. It may also produce parts with some sharp edges and burrs, so additional processes may be required if edges and burrs are unacceptable for those features.

There is hands-free production — and then there is fully automated “lights out” production. Learn about the challenges in our blog Barriers to Lights Out Operation in Precision Machining.

Get some machinists’ tips on how to keep the production of small, complex parts cost-effective in our blog Top 5 Challenges in CNC Machining Services Explained.

As is true of virtually all cutting and small parts machining methods, different materials behave differently, and the size and shape of a component also have a big impact on the process. However, in general the process of precision CNC machining offers advantages over other machining methods.

In Metal Cutting’s business, we typically utilize our proprietary abrasive cutting methods to cut tubing and a range of hard, soft, and specialty metals without forming a burr at all. However, for parts that are better suited to other fabrication methods, such as machining, we also offer a range of highly effective mechanical deburring techniques.

Learn about the advantages of precision CNC machining in the manufacture of small, complex parts requiring tight tolerances, smooth finishes, and repeatability.

Dopants raise the recrystallization temperature of tungsten wire and other wires, giving non-sag properties to tungsten light bulb filaments and other products.

The characteristics of the precision tubing used in liquid dispensing systems can significantly affect the fluid dispensing process and testing accuracy.

Learn the vital components of an effective quality control program and its role in ensuring metal parts meet their requirements for design and function.

Small gages such as pin gages or pin plug gages are useful tools for inspecting IDs and making sure small diameter metal tubing meets specified tolerances.

Learn the vital components of an effective quality control program and its role in ensuring that metal parts meet their requirements for design and function.

GD&T tolerances provide manufacturing guidance that must balance the need to make a part functional with the need to produce the part cost-effectively.

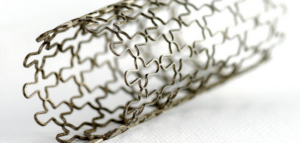

Most ring electrodes are simply cut from implant grade tubing. However, the electrodes also require various features that are produced through precision CNC swiss machining and serve purposes such as:

Unfortunately, consistent results aren’t always guaranteed. Learn what you can do to ensure calibrated measuring yields accurate results.

Deburring is an operation that is done after a specific operation is finished during the machining process. This allows the part to be smooth and free of sharp edges. It can also be an intermediate step done because of chip formation that can affect subsequent tool action, such as a chip that will wrap around a drill.

While honing and lapping are both used to fine-tune the finish and dimensions of metal parts, the two processes differ in where and how they achieve results.

For deburring of small metal parts, mass production requires the action of hand tools to be re-created by mechanical devices suited to high-volume applications.

Learn how potting can be used to create a tightly sealed package for electronic switching devices, such as the flat ribbon in semiconductors.

CNC lathes, which are also called live action tooling lathes, are ideal for creating symmetrical cylindrical or spherical parts. Like CNC mills, CNC lathes can handle smaller operations such prototyping but can also be set up for high repeatability, supporting high volume production.

When a single part has multiple tolerances that conflict, the tighter, more challenging tolerance must guide production and ultimately drives the part’s cost.

A statistically valid sampling plan in quality control provides a high level of confidence that if the sample is acceptable, the entire lot is acceptable.

For the purpose of programming a tool to achieve deburring, a burr means more than just an extra bump hanging on the corner of a part. It can also be a sharp edge created by the machining process itself.

The Swiss machine has evolved and improved since the original Swiss lathe was invented, making the modern method an important part of precision CNC machining.

While deburring on the machine is an additional operation that will increase cycle time, it is almost always faster than doing the necessary secondary operation on the parts after machining. So overall, deburring during machining will reduce the vendor’s lead time for a customer to get the part.

Learn why manufacturers, designers, and engineers need to keep metal expansion from heat in mind when they create part specifications and decide how precise the part’s dimensions need to be.

Copper tungsten electrodes combine the thermal resistivity of tungsten with copper’s resistance to DC arcing, making them a smart choice for EDM of carbides.

A 5-axis mill has three traditional axes and two additional rotary axes, enabling the workpiece to be rotated as the spindle head moves around it. This enables five sides of a workpiece to be machined without removing the workpiece and resetting the machine.

How does laser cutting compare with other precision metal cutting methods? Watch this video to learn some of the pros and cons of this metal cutting method.

Celebrating 50 Years of Precision Manufacturing: Metal Cutting Corporation is genuinely thrilled to say we have just passed a significant milestone in our company history.

Pull rings are a crucial component of steerable catheters and sheaths. Located at the tip of the device and connected via wire or cable to a control lever in the handle, the pull ring is what pulls the catheter or sheath tip in one direction or another, allowing a surgeon to guide the tip through veins or arteries.

For intricate geometries, sharp corners, unparalleled wear resistance, excellent cutting speeds and machinability, copper tungsten is the material of choice.

Finding a supplier who can deliver quality and on-time service can be tough, especially when it comes to the medical device and other heavily regulated industries. This guide makes it simple.

In material sourcing for the production of precision parts, avoiding non-standard material sizes can help to control costs and optimize for manufacturability.

Learn how additive manufacturing (AM) — one of today’s fastest growing technological innovations — is changing the face of contract manufacturing everywhere.

Milling is a machining process that uses a rotating, cylindrical cutting tool to remove material and create shapes. Milling equipment, known as a mill or a machining center, accomplishes a universe of complex part geometries on some of the largest objects machined metal.

Laser printing of metal is popular for a number of applications, but can you use it for printing of metal for such large quantities of such small parts?

Medical electrodes are used to deliver an electrical signal for purposes of cardiac pacing, defibrillation, and neurostimulation systems. Generally made from MP35N® nickel-cobalt alloy due to its electrical properties, the electrodes are usually assembled at the end of a lead and come in contact with tissue to deliver the signal to the treatment area.

In particular, precision CNC Swiss machining is frequently used where the goal is to produce very small, tight tolerance parts that have complex geometries.

Incandescent bulbs made with tungsten wire filaments continue to be used in automobile turn signals despite the parallel adoption of newer LED technology.

The world of drills is so vast, you could write a book on it, and the availability of drills has exploded. Today, there are drills of remarkably small diameters — as small as 0.002” (50 microns or 0.051 mm). Of course, the length and diameter ratios apply, so there are limitations to how deep you can drill with ultra-small diameter drills.

There are 5 key areas that should never be left blank when filling out your request for cutting quote. Do you know what they are?

What is lapping? In the right hands, this little-known process can produce parts with highly polished ends, tight length tolerances, and extraordinary flatness.

Learn why a small diameter metal probe requires choosing a material that is strong enough to maintain the probe’s shape, straightness, and direction.

Multi-axis CNC turning centers and Swiss-style lathes can accomplish multiple machining operations using a single machine. This makes them a cost-effective option for complex geometries that would otherwise require multiple machines or tool changes using equipment such as a traditional CNC mill.

This is precisely the type of operation for which end mills were created. A drill would never be used to side cut, because the drill will snap and it is just generally a bad technique. The only cutting edges on a drill are at the point of the drill, not on the side.

A vertical machining center is a mill in which the spindle axis is aligned in a Z-axis direction. These vertical machines can be further divided into two types:

As for surface finish, there are tools that will produce not only an acceptable surface finish, but also a mirror-like finish on portions of the work product.

Precision CNC mill centers are available with multiple axes. A 3-axis mill utilizes the X, Y, and Z axes for a wide variety of work. With a 4-axis mill, the machine can rotate on a vertical and horizontal axis and move the workpiece to allow for more continuous machining.

With its ability to create complex and tight tolerance parts efficiently and cost effectively, it is no wonder that precision CNC machining — and in particular, the Swiss-style automatic lathe — continues to be a mainstay in many machine shops and manufacturing operations.

Get an expert machinist’s perspective on how CNC metal cutting has evolved in the age of tight tolerance, micro-machining of small parts.

Rotary broaching is a tool where the material is spinning and the broach spins but stops once it engages with the material. From there, the broach feeds in to remove material to the desired depth and finished geometry.

Machining often leaves behind sharp features that need to be deburred, such as at the top of a hole (with a corner feature) or at the bottom of a through hole. Sophisticated deburring techniques can also include ID bottom hole deburring, where you interpolate a tool to break the edge.

Surface grinding services utilize precision surface grinding methods to make cubic metal parts square and parallel or the ends of metal rods perpendicular.

In the machining of small metal parts, a threading process is used to create precision threads on the outside diameter (OD) or inside diameter (ID) of the part. There are four methods for producing OD threads:

For a wide range of features, such as threads, holes, and steps, subtractive CNC Swiss-style machining even matches newer additive methods such as 3D laser printing in dimensional end results.

Of course, deburring tools programmed into the sequence will deburr, although usually achieving 90% of the finished requirement at most, leaving some features for final hand finishing.

Also known as bone screws, anchors are used in a variety of orthopedic and orthodontic applications. Often made from titanium, their primary use is to help repair bone fractures by producing compression that holds a bone in place so it can heal more quickly. Anchors are also used in fixation of soft tissue (such as tendons) or attaching teeth or medical implants to bone.

The straightness properties of tungsten wire make it valuable for small diameter tungsten probes used in semiconductor wafer testing and neural activity testing.

For EDM electrodes, copper tungsten offers excellent electrical conductivity, DC arcing resistance, thermal conductivity, and wear resistance.

With the eddy current testing procedure, there are a number of variables that have an effect on ECT, what it can find, and what it cannot find.

For Swiss-style machining, almost any drill can be attached to a screw machine tool holder, within the size limitations of the machine. The drill is then used to remove material and create features such as through holes, cross holes, and blind holes of various sizes.

Different precision metal cutting options vary in characteristics and appropriate applications, making the choice not quite so easy. This guide will help.

The process of creating a vacuum atmosphere, either repeatedly or in one-time production, is an important part of electronic component manufacturing.

Electrochemical cutting (ECC) combines electrochemical erosion and grinding to produce a burr-free, shiny surface to a tight tolerance of ±0.005” (0.127 mm).

Depending on the toughness of the material being machined, slotting may involve drilling a hole and then using an end mill to rough out the desired steps and dimensions. From there, the end mill does a finishing pass to side cut around the walls and complete the slotting.

Utilizing a controlled environment helps to minimize the effects of heat expansion and other temperature issues on the measurement of metal parts.

Reaming is more commonly used for requirements such as a tight tolerance straight hole that is going through a tube. Reaming will follow the hole previously made by a drill. If the drilled hole is not straight, the reamed hole will also not be straight.

The following are just some examples of parts that engineers design into medical devices and that are frequently produced using precision CNC Swiss machining.

Learn how to prevent and detect surface flaws in the glass to metal seals used in the manufacture of a wide range of electronic products.

Custom bushings that are Swiss machined for use in catheters and other medical devices allow the devices to function at a high RPM while resisting wear.

In Metal Cutting’s world of very small diameter parts, ID threading presents a different kind of variable. That’s because we usually don’t have the luxury of a perpendicular tool, due to the extremely small IDs we are requested to tap.

Precision flat lapping and other lapping techniques can be used for small parts requiring tight control of surface finish, flatness, thickness, and parallelism.

At Metal Cutting, we generally use a turning tool for deburring anything on the diameter geometry — programming the CNC Swiss machine to automatically do a finishing pass to add a radius or chamfer, depending on the part. (Learn more about radius corners and deburring in mass production.) For deburring holes, we use an angled carbide spot drill, chamfering tool, or other simple tool capable of breaking the edge

Customs bushings are sometimes used at the tip of catheters and other medical devices where the tip must rotate at a high rotational speed. The purpose of the bushings is to reduce wear on the end of devices ranging from dental drills to atherectomy devices used to remove plaque from arteries.

Over time, we’ve developed a special appreciation for tungsten and what it can do. Learn some interesting facts you may not have known.

When designing a part, remember that different tolerances may require different processes, and not all processes can produce results to the same tolerance.

Industry Trend No. 3: Rising labor costs overseas are one factor in the move away from outsourcing and toward reshoring of some businesses and factories.

When choosing a resistance welding electrode for any application, a thorough understanding of material properties helps to avoid production line issues.

Industry Trend No. 2: Manufacturing globalization and regionalization provide opportunities for partnership, innovation, competitive advantage, and growth.

For measuring and inspecting the ID of small parts tubing, pin gages or optical measurement systems help ensure that small tubing will meet specifications.

In addition, once a tool path has been designed and a machine is programmed, it can run a part any number of times. This provides a high level of precision and repeatability, which in turn makes the process highly cost effective and scalable.

With the ability to work with just about any material and any production volume, precision CNC machining is often the fabrication method of choice for a wide array of manufactured components.

For design engineers, R&D teams, and manufacturers that depend on part sourcing, precision CNC machining allows for the creation of complex parts without additional processing. In fact, precision CNC machining often makes it possible for finished parts to be made on a single machine.

Deburring a part helps with fit and the accurate measurement of the part. It also aids in preventing injuries such as cuts and splinters in people who will handle or use the finished part.

Drills are typically made of hardened steel or carbides, some with abrasive features. The point of a drill is typically angled between 118° and 135° (sometimes 145°), depending on the material being machined, with a 118° being the standard angle. It is used on all drills for all materials, usually following a spot drill or center drill application.

Thousands of resin compounds have been developed to expand the design options for tubing in medical devices. Yet, there are number of myths. Learn why plastic may not be a better choice to metal tubing in medical applications.

Learn how better materials for resistance welding electrodes speed up your welding operation. This white paper is designed to help you make a successful electrode materials choice.

With a metric tolerance chart, you need to account for the upper and lower tolerance spec limits when converting between standard and metric measurements.

Tungsten, also known as wolfram or volfram, has a high melting point and other interesting properties that are useful in many industries and products.

While the most familiar use of tungsten (incandescent light bulbs) continues to fade, the unique range of properties continue to make tungsten wire irreplaceable for a number of products and applications.

With precision CNC machining, you can get the scalability and speed needed for this type of high-volume production. In addition, the high repeatability of precision CNC machining gives you parts that are all the same from start to finish, no matter how many parts you are producing.

In circular runout vs. total runout, the first controls variation in circular features of a part while the other controls variation in the entire part surface. Learn the difference and how to measure them here.

In the medical device industry, precision CNC machining is particularly well suited to a wide range of applications, including surgical tools, catheters, surgical needles, replacement joints, and components for respirators and ventilators.

Explore the advantages of pure tungsten and pure molybdenum as alternative materials for use in spot welding electrodes.

Is precision CNC Swiss machining the right choice for your small parts requirements? Learn more in our free white paper Swiss Machine FAQs: What to Know About the Swiss Lathe and Its Advantages in Precision CNC Machining.

While laser cutting can produce a small kerf and tight tolerances, other precision cutting methods may be preferable for 2-axis cutoff of small metal parts.

The metal shearing process can be quick and inexpensive for cutting some simply shaped parts, but it has disadvantages including burrs and end deformation.

On a regular chucker lathe, the part sticks out and is pushed away — that is, deflected — as you start removing material. But on a CNC Swiss machine, the material moves and the tools are stationary, so there is far less deflection.

Learn the key parameters for choosing a method of 2-axis precision cut off of metal parts based on part type, material type, and part dimensions.

In comparing common tungsten uses in 2007 and today, it is clear that tungsten remains one of the most widely used and beneficial of the refractory metals.

Milling machine

Learn how to optimize for manufacturability through a unified approach to product design and the creation of a thorough and detailed request for quote (RFQ).

The growing demand for very small, tight tolerance components has ensured the continuing use of precision CNC Swiss machining in a wide range of industries that commonly source parts. This includes electronics, robotics, aerospace, and other markets where the precision of small components is critical to the form and the function of countless end products.

When polishing metal parts for 3D printed medical devices, the goal is to achieve the proper surface finishes while maintaining the device’s complex design details.

However, in general precision CNC Swiss machining uses one of two methods used to produce ID threads: single point threading and tapping. For ID threads, single point threading is accomplished in basically the same way as described above for OD threading, except in this instance on the ID of the part.

Precision tubing plays a vital role in helping to ensure the accuracy of liquid dispensing systems used in many biotechnology and laboratory environments.

You could use reaming, which is much faster than boring, to make a precise hole. However, reamers wear out, creating additional issues.

Learn 7 simple rules to help ensure that calibrated measuring yields accurate and consistent results for your small parts manufacturing.

While Swiss machines can have live tooling where you could mount a spinning cutting wheel (which Metal Cutting knows well from our cutting business), it is usually not ideal for making a slot. And you definitely could not use a grinding wheel to make a closed slot. Because of the radius of the wheel, which wears over time, you’d never be able to have an inside radius of a perfect, perpendicular 90°.

Adherence to ISO 9000 standards by an organization tells customers that it is committed to implementing structured quality management practices.

Learn how the properties of copper tungsten reduce or eliminate the challenges posed by those materials when they are used in their pure forms.

Waterjet cutting is typically used to cut complex shapes from large, flat sheets of metal but may not be the best choice for 2-axis cutoff of small parts.

When all of the required machining operations are completed, the part is cut from the stock for further processing, if needed. The CNC lathe is then ready to repeat the operation, with little or no additional setup time usually required in between.

The Swiss screw machine has, quite literally, been around for centuries and shows no sign of stopping. You can read about the evolution of the modern Swiss lathe in our blog The Swiss Machine in Today’s Machine Shop.

And if you have challenging geometry within the hole that needs to be held to a specific diameter or dimension, boring is the preferred method over reaming.

Specifying the magnification level and details of how a material surface must be examined helps to ensure that parts will pass inspection and meet your needs.

With a CNC Swiss-style automatic lathe, the stock material is fed through a sliding head spindle into a guide bushing. This allows the tool to cut the material closer to the point where the material is supported, making the Swiss machine especially beneficial for long, slender turned parts and for micromachining.

Proper electrode design and construction is essential to ensuring consistent weld quality, minimum electrode sticking, and maximum electrode life. Learn how electrode design can impact your prod line.

Taking a computer aided design (CAD) model provided by a customer, an expert machinist uses computer aided manufacturing software (CAM) to create the instructions for machining the part. Based on the CAD model, the software determines what tool paths are needed and generates the programming code that tells the machine:

Learn about the important role of machining and tooling in the manufacture of metal parts for today’s fuel injection systems.

As important as inspections are, 100% inspection requires time and cost without a guarantee of 100% compliance. See what a sampling plan is and how it solves this challenge.

GD&T cylindricity is a three-dimensional tolerance feature used to indicate both roundness and straightness along the entire axial length of a cylindrical part.

Get answers to common questions about dissimilar metals regarding high and low conductivity electrodes and friction stir in the construction of an electrode.

It may be tempting to assume that a very tight tolerance should be your default choice. But, when they aren’t essential, it could increase your costs needlessly.

Circularity tolerance based on diameter helps to control roundness and ensure that small precision metal parts fit properly, move smoothly, and wear evenly.

Surface finish requirements are just some of the details critical to completing an RFQ that will help you optimize for manufacturability.

Industry Trend No. 1: Increased exporting and global trade has a positive impact on revenue, growth, and competitiveness, while expanding a manufacturer’s customer base.

In precision CNC Swiss machining, the machinist can program the screw machine for deburring so that there doesn’t need to be a separate deburring operation afterwards.

Double disk grinding provides dimensional accuracy for metal part applications that require tight tolerances, parallelism, flatness, and thickness control.

However, here we will focus on the milling and turning processes — two subtractive methods that are widely available and frequently used for precision CNC machining.

Our name might not give it away, but precision cut off of tight tolerance, small metal parts is at the core of our business.

Calibration standards for devices and equipment used in measuring, inspecting, and manufacturing of precision metal parts can pose some unique challenges.

Learn why precision CNC Swiss machining is used in the production of medical electrodes made from MP35N® for electrical signal delivery devices.

High precision internal grinding methods such as ID grinding and honing are used to achieve smooth finishes and tight tolerances on bore, hole, and tube IDs.

It begins with drilling or forming a starter hole smaller than the intended finished size. Then a tool called a boring bar is used to open the hole up to the desired finished size.

People often ask Metal Cutting Corporation if we do “metal fabrication” — and the truth is, the answer depends on how you define the term.

Broaching is done with a precision ground broaching insert. Depending on the geometry you need, you can buy or custom-make (grind) your own broaching tool.

In general, vertical machining centers are more prevalent because they can be as powerful as horizontal machining centers and can handle very small parts. In addition, vertical centers have a smaller footprint than horizontal machining centers.

Learn about the five major challenges to consider when choosing CNC machining services and a partner for the manufacture of complex and precise small parts.

There are some very specialized methods of CNC machining, including wire EDM (electrical discharge machining), additive machining, and 3D laser printing. For example, wire EDM uses conductive materials — typically metals -— and electrical discharges to erode a workpiece into intricate shapes.

The key to calibration tolerance is understanding both what a device is capable of doing and the tolerance to which the device has been calibrated.

Drilling is a process that is often used in high precision machining to remove material before performing finishing operations such as threading, tapping, boring, reaming, or broaching.

Broaching is mainly used to make geometric shapes on a part for special tool use. An example is a socket-head cap screw with an ID hex used with a hex wrench to drive in the screw. Other examples include the very common Phillips head, a Torx head, and various proprietary shapes designed for security purposes so that the fastener cannot be easily removed.

CNC lathes can also be set up for relatively hands-free production, which makes them widely used in the automotive, electronics, aerospace, robotics, and medical device industries.

With profile of a line vs. profile of a surface, the former controls variation at specified cross sections while the latter controls the entire feature surface.

Metal tubing continues to play a critical role in medical device manufacturing, but with the array of available plastic materials it can be hard to determine which material is the right one.

A metal surface finish chart is a handy guide to standard surface finishes and characteristics such as measurement units, conversions, and typical Ra values.

Metal Cutting’s methods for cutting metal tubing, such as thin wall steel tubing for medical devices, are unique compared with machining and laser metal cutting.

Thin-wheel abrasive cutting is an ideal method for high-volume 2-axis metal cutoff that requires precision, tight tolerances, no burrs, and a smooth end finish.

A lathe — also called a turning center — has one or more spindles, and X and Z axes. The machine is used to rotate a workpiece on its axis to perform various cutting and shaping operations, applying a wide range of tools to the workpiece.

Using an evolving array of tools and techniques, along with the consistency and repeatability advantages of CNC automation, Swiss machining can enable a workpiece to be finished to precise specifications in a single operation, with little or no intervention by a machine operator.

Because automatic CNC Swiss machining is not an abrasive process, the deburring technique that is used requires running a tool over the area in question. Various tools can be used, but typically the tool needs to have a cutting action — which means removing the burr will yield a chamfer or radius feature.

Many pull rings are simply cut from 304 grade stainless steel tubing. However, if they have specialty features or are made from another material that is not available in standard tube sizes, precision CNC Swiss machining may be required. For instance, when a pull ring is designed with grooves for the wires, OD steps, or slots for polymer flow, it is easier to machine them from solid bar stock.

In turning, unlike milling, the workpiece spins. The part stock turns on the lathe’s spindle and the cutting tool is brought into contact with the workpiece.

Turning is the process of cutting or shaping a workpiece on equipment called a lathe. Typically, the lathe spins the workpiece on a vertical or horizontal axis while a fixed cutting tool (which may or may not be spinning) moves along the programmed axis.

Learn why resistance welding electrodes require a material with the right combination of thermal conduction, electrical resistivity, and reactivity.

The creation of new specialty metals offers alternatives to stainless steel for components used in medical device applications.

However, in general, CNC mills all utilize a rotating spindle to cut away unwanted material. They are used to cut hard metals such as steel and titanium but can also be used with materials such as plastic and aluminum.

With these RFQ tips, you can not only speed up the quote process, but also ensure you get the part you want and a cost estimate that is as accurate as possible.

89 Commerce Rd Cedar Grove, NJ 07009 General Information 973 239 1100 sales@metalcutting.com Copyright © 2024 Metal Cutting Corporation

Learn how the guide bushing and other features of modern CNC Swiss screw machines eliminate deflection to improve efficiency, consistency, and accuracy.

Custom bushings are often made from MP35N®, Elgiloy®, or other materials that provide better wear resistance than the 304 grade stainless steel used in so many medical devices. Because tubing is not readily available in custom sizes in these materials, the tips have to be uniquely made. That means the bushings are often machined to the necessary final shape using a CNC Swiss-style lathe.

CNC lathes can also accommodate a variety of automatic bar feeders, which reduce the amount of manual raw material handling and provide advantages such as the following:

Like an end mill, a boring bar can be far more precise in these applications than a drill. For example, if you need an ultra-precise large hole — such as a 0.25” (6.35 mm) hole with a very tight tolerance of ± 0.0002” (0.0051 mm) — it would be virtually impossible to drill that in one pass with a quarter inch drill. (Plus, that would be a very expensive drill.)

Choosing the right resistance spot welding electrode for an application depends on understanding critical properties of the different electrode materials.

How to mill small metal partsat home

While automation plays a growing role in precision machining, lights out operation is still more a fantasy than a reality for most small part manufacturing.

Most Swiss screw machines can be used to do deburring, an important but often overlooked process. Rather than making something, the purpose of deburring is to remove something — namely, to remove unwanted burrs and sharp edges on machined parts.

Wire EDM cutting advantages and disadvantages for 2-axis cutoff depend on factors including the material used, part parameters, and surface finish requirements.

Learn more about the principles of centerless grinding and how it can be used to achieve tight tolerance surface finishes on small cylindrical metal parts.

A CNC lathe can perform a number of operations, such as drilling, threading, boring, reaming, facing, and taper turning. Different operations require tool changes and can increase cost and setup time.

While a skilled machinist can use a manual lathe to make a quality part in quantities of 10 or 100, what happens when you need 1,000 parts? 10,000 parts? 100,000 or a million parts?

A fully complete RFQ tells a story about the buyer, the company, and the end product and its use — information we can use to provide the right quote (and the right price).

In the next section, we’ll take a look at some of the equipment and the processes that are most frequently used in precision CNC machining.

Follow these tips on how to choose a vendor for cut off metal parts and get the results you want for your precision manufacturing needs.

With its unique properties, tungsten wire is used in a wide range of industry applications, from tungsten filament wire bulbs to tungsten thermocouples.

Learn how tungsten as an alternative to precious metals can help you achieve uncompromising quality and still keep your budget on track.

While an automatic lathe can do simple 2-axis cutoff of metal rods and tubes, it is designed for more complex, multi-step machining operations.

Learn about the variables to consider when choosing the best resistance welding electrode material for specific resistance spot welding applications.

For many of the small metal parts and precision metal components that are used in a wide range of manufactured products, precision CNC machining is often the fabrication method of choice.

Flutes are grooves that can vary in size, shape, and the number on the bit. The purpose of a drill’s flutes is to ease the exit of the chips as the material is being cut. The exception is a spade drill, which doesn’t have flutes because it is used for shallow hole drilling.

In addition, a Swiss lathe has both a collet and a guide bushing, to further reduce deflection and machine the parts more precisely. All the action is at the edge of the guide bushing; the correct length of material is fed out, machined, and parted off, then another length of material is fed.

Precision metal grinding is often the best way to remove small amounts of material and achieve the right finish or tight tolerance dimensions on part surfaces.

While CNC machining can produce an array of complex, precision metal components, there are some challenges to the process you need to be aware of.

In addition to offering simple 2-axis machines in which the tool moves in the X and Z axes, precision CNC equipment include multi-axis models in which the workpiece can also move. This is in contrast to a lathe where the workpiece is limited to spinning and the tools will move to create the desired geometry.

Eddy current testing is an important method of nondestructive testing that is often used to inspect for flaws in the surface or sub-surface of metal materials.

While both mills and lathes are available in manual models, CNC machines are more appropriate for purposes of small parts manufacturing — offering scalability and repeatability for applications requiring high volume production of tight tolerance parts.

The two basic types of milling machines are known as vertical machining centers and horizontal machining centers, where the primary difference is in the orientation of the machine spindle.

Tungsten wire continues to be a product that has a large number of diverse applications, for many of which there is no known substitute. Find out why tungsten remains widely used.

With a boring bar, you have better tool life and the chances of catastrophic tool wear are small. In addition, the machine can be adjusted to ensure the correct hole size even as the tool itself experiences wear.

Certain drills are used for specific processes. For instance, a #7 drill is used to make a hole to tap a quarter-twenty thread inside a part.

Different milling machines vary in their sizes, axis configurations, feed rates, cutting speed, the milling feed direction, and other characteristics.

Older style lathes were cam-driven, making them relatively primitive. Today’s Swiss-style lathe with CNC is leaps and bounds better, in both accuracy and efficiency.

Tapping creates threads using a tool called a tap, which has a specific pitch and diameter according to the threading that you want to achieve. There are three types of tapping tools:

Drills come in a range of sizes and with different types of flutes. Here at Metal Cutting Corporation, most of the drills we use for precision CNC machining are standard, fractional, decimal, wire, and letter sizes.

Learn how precision cut off and stamping compare in achieving distortion-free flatness, a sharp edge, and the precise exterior diameter needed for a spacing ring.

While graphite is often used, the properties of copper tungsten make it an ideal material for EDM electrodes for certain applications.

In a horizontal machining center, the mill’s spindle axis is aligned in a Y-axis direction. The horizontal structure means these mills tend to take up more space on the machine shop floor; they are also generally heavier in weight and more powerful than vertical machines.

These multi-axis configurations allow for the production of more complex geometries in a single operation, without requiring additional work by the machine operator. This not only makes it easier to produce complex parts, but also reduces or eliminates the chance of operator error.

Gold-plated tungsten wire is useful in filtration, printing, copying, and other applications, and as an alternative to precious metals in some medical devices.

The electrochemical grinding process is a highly specialized method that combines surface grinding, chemistry, and fixturing, and has limited applications.

Metal Cutting’s methods for cutting metal tubing, such as thin wall steel tubing for medical devices, are unique compared with machining and laser metal cutting.

Cold sawing can do high-speed, burr-free cutoff of rods, tubes, and extrusions, but it is not ideal for very short lengths, smalls ODs/IDs, or hard metals.

Slotting is used for fitting parts together, either by welding or pressing, and is primarily accomplished through the use of an end mill.

Swiss screw machines are often called on to make small parts such as screws that will need to be moved either by a machine or by a human being using a tool such as a wrench. The top of the screw can be a Torx head, Phillips head, flat head, or many other shapes, including proprietary designs for security.

The properties of tungsten wire are valued in the medical device industry, for use in electrocautery, electrosurgery, neural probes, and other applications.

Metal Cutting Corporation uses visual and mechanical methods of metal inspection to help ensure that small parts meet customers’ manufacturing requirements.

Metal Cutting utilizes lapping and machining as well as other techniques to achieve flatness vs. parallelism for metal cut to length.

Reaming is done with a tool known, not surprisingly, as a reamer. As noted previously, reaming is faster than boring. However, there are definite downsides to reaming, including the fact that the hole being reamed will get smaller and smaller — and so, less precise — as the tool wears out.

Precision CNC Swiss machining is often used to produce bone screws and anchors with the features needed for a wide range of orthopedic and dental applications.

Using coded programming instructions, CNC precise machining allows a workpiece to be cut and shaped to specifications without manual intervention by a machine operator.

Learn how the right electrode material, design, and construction can help to prevent bonding problems in resistance spot welding electrodes.

Learn how best practices as well as material and design considerations have an impact on the life and effectiveness of resistance spot welding electrodes.

In addition, the use of high-pressure coolant with precision CNC machining ensures that chips do not get into the works, even when utilizing a machine with a vertically oriented spindle.

There are a number of different types of lathes, but the most common are 2-axis CNC lathes and Swiss-style automatic lathes.

Learn the advantages of copper tungsten electrodes for resistance spot welding of wire harnesses in battery electric vehicles (BEVs).

Surface flatness is an indicator of all points along a surface lying in the same plane, with the highest and lowest points within the flatness tolerance range.

For example, polygon machining is often used to create the hex (hexagon) shape that is very commonly used as a wrench head. End mills are an ideal tool for polygon machining and are frequently used with CNC Swiss-style automatic machines.

The tool cannot physically go around the part. The material rotates, allowing the tool to perform the programmed operations. (There is a subset of lathes in which the tools spin around a spool-fed wire, however, that is not covered here.)

0086-813-8127573

0086-813-8127573