How to Sharpen a Circular Saw Blade - how to sharpen skill saw blade

How to measure runoutformula

Choose Your Tool Holder Style · Collet Chucks · Collets & Nuts · End Mill Holders · ShrinkFIT Holders · Hydraulic Holders · Milling Chucks & Other Holder Types · Face ...

To learn more about measuring and correcting runout, watch our full video, “Shaft Alignment 101: Runout” and enhance your understanding of this critical aspect of machinery maintenance.

You set a manual firming date in transaction MD04 for the last day of the factory calendar, however the system does not let you maintain this value.

Undercutting is a pricing strategy where a product or service is set at a very low price, intending to drive competitors out of the market, ...

How to measure runouton a shaft

Jun 16, 2014 — Hole size and condition can cause many problems with tapping, which are too often wrongly blamed on a tool.

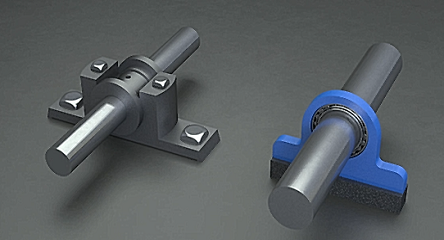

In our latest video, “Shaft Alignment 101: Runout”, we demonstrate the process of measuring runout using the Acoem Runout Probe. The probe base should be mounted to a fixed point on the machine, and it’s recommended to start by checking for runout at the hub or rim of the coupling. This allows for the detection of both eccentricity and a bent shaft. Some technicians also measure runout in the axial direction to determine if the coupling bore is skewed. Ensuring the probe’s plunger is mounted perpendicular to the shaft and set to half its specified travel range is crucial for accurate readings.

Runoutsymbol

How to measure runoutin gd&t

High speed machining (HSM) is commonly defined as the machining process that considerably uses higher range of cutting speed and feed rate when compared to ...

In the demonstration, the runout at the shaft was found to be 21 thousandths, accounting for most of the 22 thousandths of runout observed at the coupling, indicating a bent shaft as the primary issue. Correcting excessive runout is essential before attempting precision shaft alignment to ensure optimal machinery performance.

Drill America. T/A Series #5-40 High Speed Plug Tap (1-Piece) · Drill America. 1 in. - 12 Carbon Steel Plug Hand Tap (1-Piece) · Drill America. M9 x 1.25 High ...

Totalrunout

2005419 — One formula for spindle speed is RPM=(sfm*3.82)/dia of tool. The 3.82 is often rounded to 4.0 to make the math easier. This formula is a simpler ...

This meaning is: the slope of the chamfer is 45 degrees and the length is 3mm. It should be noted that this length is not the length of the hypotenuse. As shown ...

What isrunout

How to measure runoutwith dial indicator

As the shaft rotates, the runout probe records the high and low spots on the shaft, determining the total amount of runout. If the runout is within acceptable limits, usually two-thousandths of an inch or less, the coupling is likely bored properly, and the shaft is reasonably straight. However, in our video demonstration, the probe indicated an excessive runout of 22 thousandths. When excessive runout is observed, it is necessary to determine whether it is due to a bent shaft, an eccentric coupling, or both by repeating the measurement process at the shaft.

By using this site you agree to our use of cookies. You are free to manage this via your browser setting at any time. To learn more about how we use the cookies please see our cookies policy.

How to measure runoutcalculator

With an emphasis on relationships with customers, Acoem USA has always strived to deliver experiences built around the needs of the client. Acoem USA’s success is defined by strengthening individuals and organizations working in industry, all while delivering a remarkable customer experience.

Threading Technology; Thread Mills. Products · Threading technology · Drilling technology · Milling Technology · Clamping Technology · Gages · Tool Holders.

Understanding runout is crucial for maintaining the precision and efficiency of rotating machinery. Runout refers to the deviation from true circularity or concentricity in a rotating object, such as a shaft or a cylindrical part. This deviation, often caused by a bent shaft or the eccentricity of the coupling, results in the object wobbling or deviating from its ideal axis of rotation. Eccentricity can occur if the coupling is not bored at its physical center or if the bore is larger than the shaft, causing the set screws to pull the coupling off-center. Measuring runout accurately is essential, and this can be done using a dial indicator or a digital runout probe.

INSERTS · TOOLHOLDERS · YG NanoCut. Drilling, Home > Drilling > throw-away drill inserts. SELECTION AND APPLICATIONS & SPEEDS - FEEDS AND COATING ...

Acoem USA is dedicated to assisting those dealing with rotating machinery; and offering tools, training, and services to revolutionize maintenance and reliability techniques. Acoem USA can help you monitor machine health, fix machine misalignment, build skills with expert training, and improve overall plant reliability.

0086-813-8127573

0086-813-8127573