How To Use a Router - Up vs. Down Cut Bits - upcut vs downcut

ISOinsertnomenclature pdf

Insertdesignation chart

Apr 19, 2024 — Table of Content ... Choosing between CNC machining and die-casting aluminum depends heavily on your project's requirements. CNC machining offers ...

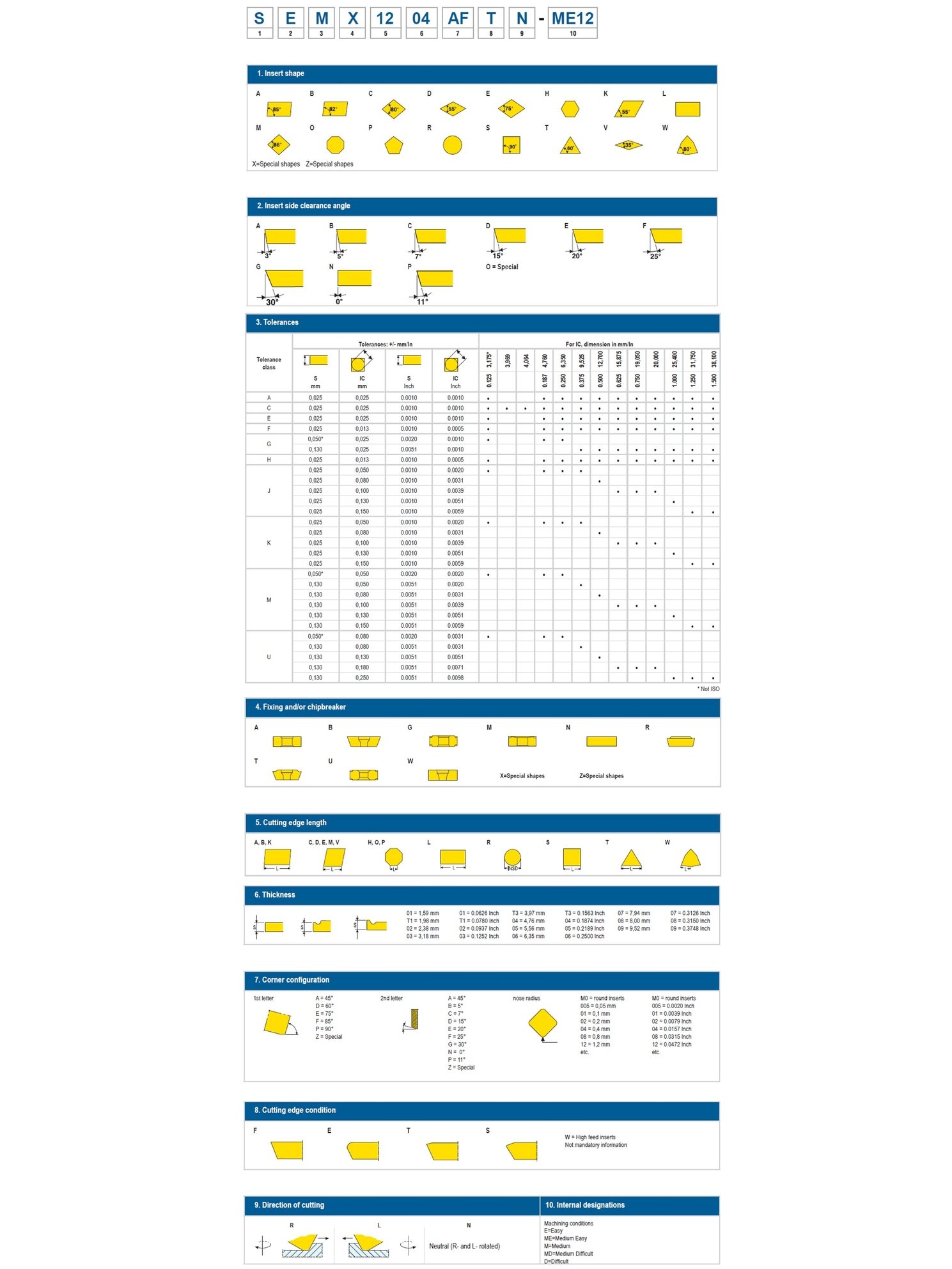

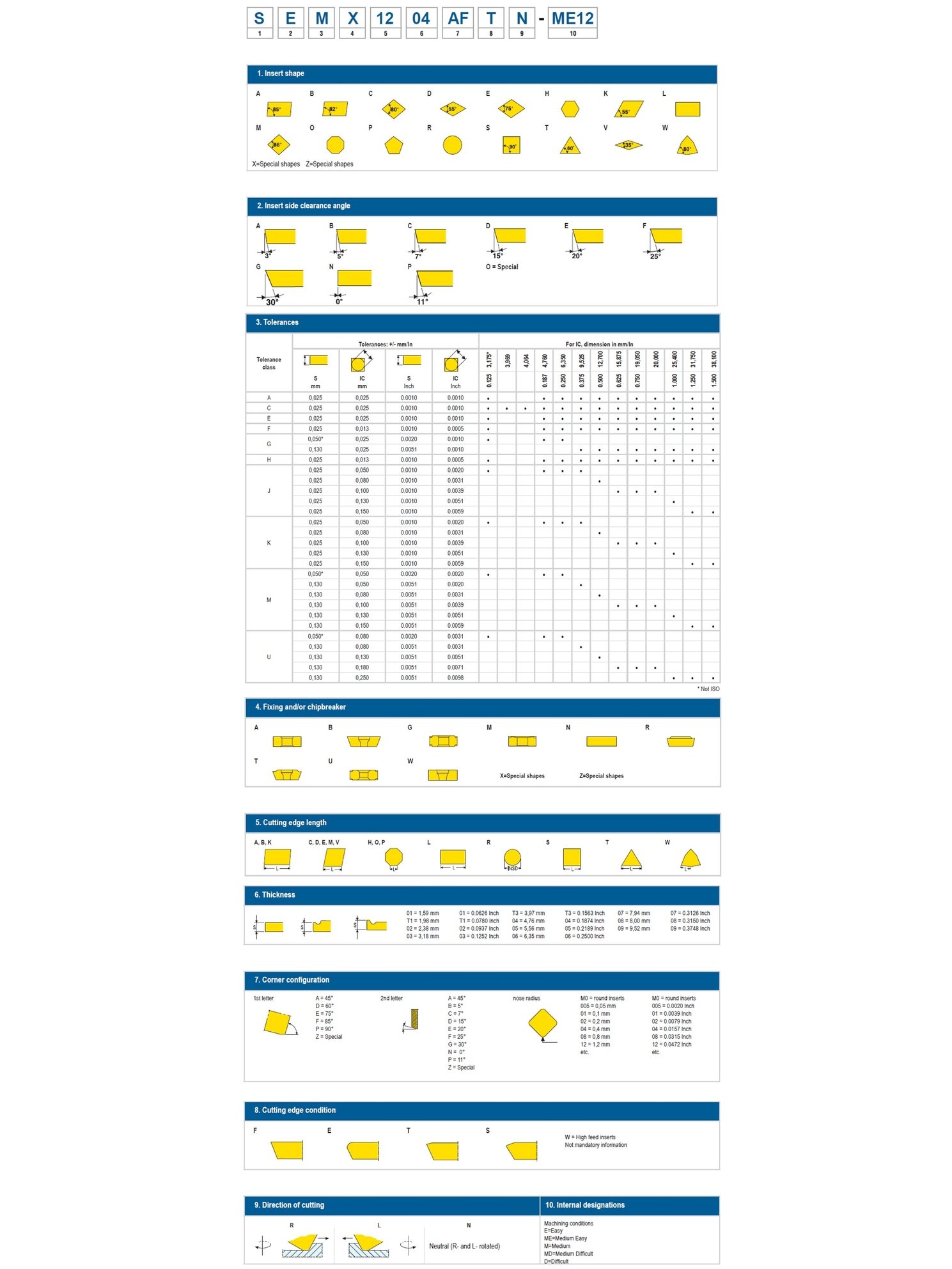

The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert.

TurninginsertIdentification chart

Jun 4, 2024 — I've pretty much stopped buying tools from Harbor Freight, unless I need a cheap wrench to grind down or cut in half to make a special tool.

We offer high-quality solid carbide end mills and tools like ball nose endmills, carbide drills, and end mill cutters that our valued customers trust and ...

Stainless Steel M · Coated Carbide. AC6000M Series. AC6020M · For Small Lathes. AC1030U. High-quality cutting edge grade suppresses adhesion and micro-chipping, ...

ANSIinsertnomenclature

ISO turninginsertnomenclature

I'm Cutting Carbs - Short-Sleeve Unisex T-Shirt - DecoExchange · Item details · Delivery and return policies · 4,582 reviews · FAQs · Meet your sellers · More from ...

WIDIA thread mills produce threads for blind and through holes with precision. Choose Victory™ solid carbide thread mill series in metric and inch ...

It's a kennemetal marketing channel. Most of what the guy has going on is great for show but doesn't fly in actual practice.

ISOcarbide Insertchart

Carbide insertidentification chart PDF

Nov 20, 2012 — .007" to .015" under should work. If you are working with bronze guides using a drill, make sure there is no rake on the drill or it can pull itself into the ...

High quality diamond tools for any requirement or job. Diamond blades, diamond chainsaw chains, core drill bits, diamond wires and floor grinding tools.

A request amend an approved conditional zoning district to allow for the development of two large light industrial buildings on 40 acres.

THE ISO designation system for indexable insertsThe ISO designation system for indexable inserts (ISO 1832) is a standardized system to name an indexable insert.The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert. This system has several advantages:Unique naming of an indexable insert (supplier independent)All important features and dimensions are clearly stated in the nameSome code positions relate to the insert carrier in which the insert can be mounted It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system. This is an example for milling inserts. For other applications, you can refer to the relevant Machining Navigator. Do you want to know more?Contact Us Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system.

0086-813-8127573

0086-813-8127573