How to use myHarvey App - harveys app

Told him to drill 1/4" first but he didn't. Upvote 1. Downvote Reply ... There is only about an inch clearance. r/Tools - Can someone ...

Difference betweenlathe andmillingmachinepdf

Nice post, It’s quite informative. People can gain a lot of knowledge from this blog post. Thanks for sharing it with us.

Mill Machine

Your masonry bits are intentionally made slightly oversized to accommodate the expansion of materials like concrete or brick which can cause bits to become clogged.The larger hole also helps with easier insertion and fitting of anchors.This is a common issue and not necessarily a flawjust a design choice to ensure a better fit and function.

Tungaloy America 6811657 Carbide Turning Insert, CNMG 642 TM AH120, Diamond, 0.7500 in Inscribed Circle, 0.2500 in Thickness, 0.0314 in Corner Radius.

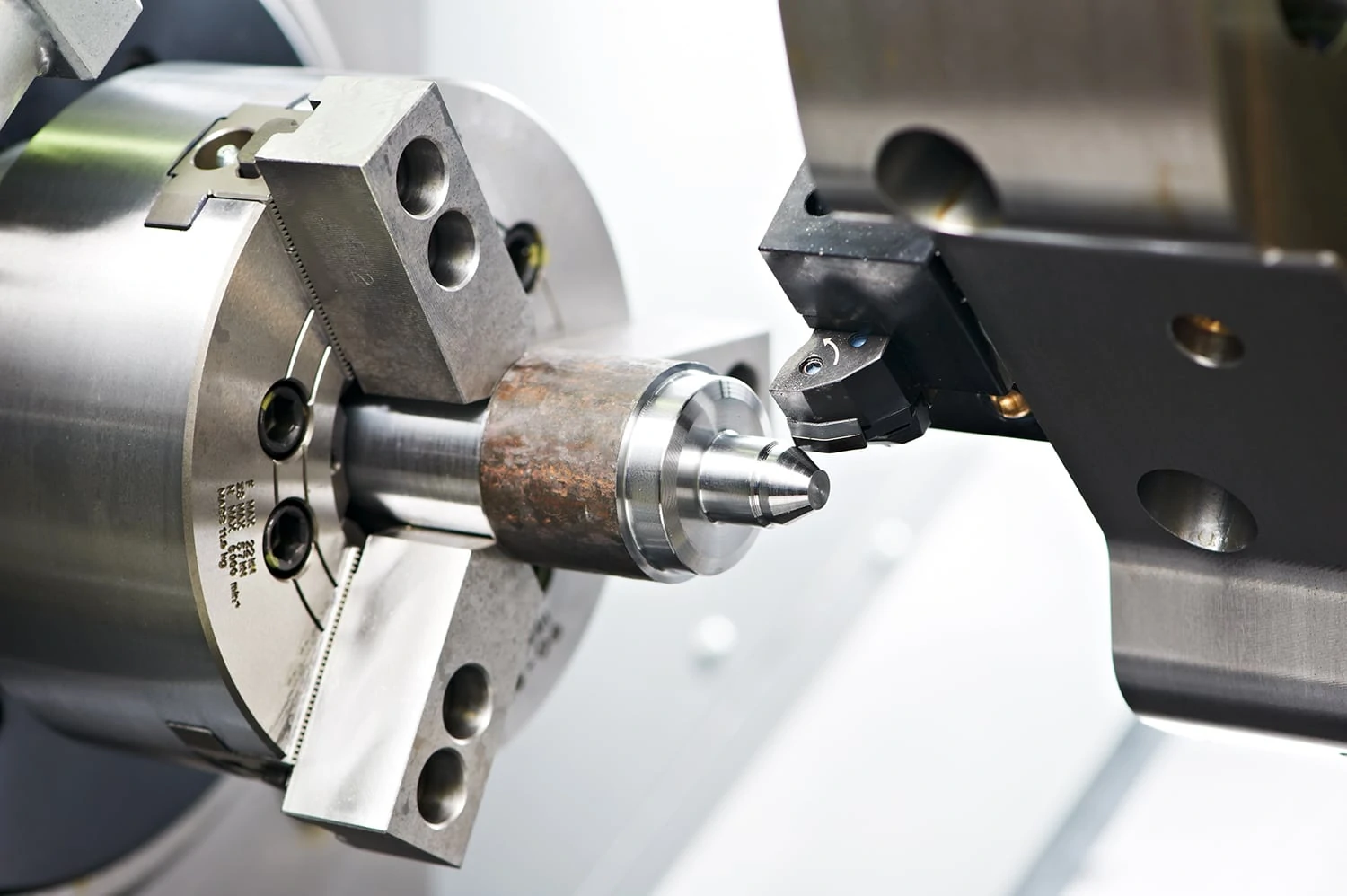

Thank you for sharing this information about CNC Machine. I would like to add, Both lathes and milling machines are used to remove material from a workpiece. Lathes, however, involve rotating a workpiece against a single-bladed cutting tool, whereas milling machines involve rotating a multi-bladed or -pointed cutting tool against a stationary workpiece

Lathe machines and milling machines can vary widely based on features. It is certainly possible to spend tens of thousands of dollars on a lathe, or just a couple thousand for a basic machine. The same can be said for milling machines, which can range from small hobby machines that run a couple of thousand dollars up to massive industrial machines that can cost in the 6 figures. I would suggest speaking to your local dealer for more information on cost.

Your observation about masonry bits being oversized is intriguing and raises a valid point. It seems manufacturers design their bits with a slightly larger diameter for efficient cutting, ensuring they can penetrate tough materials.

machines and lathe machines. My husband has been really curious about what they do. That is really cool that lathe machines spin about a

Lathe andmillingMachineOperator jobs

Nov 13, 2016 — I will usually leave .005 on the floor, .010 on walls for just about anything. If need be, I'll do a semi-finish pass on the wall, leaving .005 ...

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Hi Leo G, Yes, I'm probably overthinking this. I want to drill holes in a shower wall. Ceramic tile on a 3/4" mortar bed. Using typical 1/4" plastic anchors as provided by the manufacturer of the product, along with the stainless screws included. I also have tapcon screws of the same length, but I don't think plastic anchors are meant to be used with tapcons. If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

Ok, ok. Time to get back to work. We all know masons cannot measure anything smaller than a brick, so the oversize just doesn't matter. The holes in masonry are sloppy, especially when compared to the holes in wood made by good bradpoints or Forstner type bits.

I want to drill holes in a shower wall. Ceramic tile on a 3/4" mortar bed. Using typical 1/4" plastic anchors as provided by the manufacturer of the product, along with the stainless screws included. I also have tapcon screws of the same length, but I don't think plastic anchors are meant to be used with tapcons. If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

Hand-Held Release Liner and Back Slitting Cutting Tools. Be the first to review this product. Skip to the end of the images gallery.

Global Fusion Coating Inc. | 691 followers on LinkedIn. Internal/ External Pipe Coating Specialists, Abrasive Blasting / Sandblasting, Field Coating ...

To complement our Alu Power range, Korloy's A+ End Mills are our first choice high performance cutter for aluminium finishing applications. These 2 or 3 flute ...

1/2" Chamfer Mill 120 Degree Straight Point Single End Flat Tip, 2 Flute, Carbide, AlTiN, TITAN, LOC=.121" OAL=3" SHK=1/2" TIP DIA=.080"

Good piece on the difference between milling machines and lathes, thanks. I have a lathe at home (although I have experience with milling machines) and I’m looking to transition over to CNC. When I started doing research, I realized that I needed to know more about these CNC machines is and how they actually work – I came across this page (https://carveyourcreation.com/what-is-a-cnc-machine) and it’s a great help in this respect, but it also talks about a way to build your own CNC machine at home. I hope you don’t mind if I share the link. I’d like to discuss some things and I’ll be calling you shortly. Thx again

I was looking for this information relating to such milling machines vs lathes. You have really eased my work by posting this article, loved your writing skill as well. Please keep sharing more, would love to read more from you!

Thanks for explaining the difference between the milling machine and the lathe machine. Through this blog, I get to know the amazing facts related to both machines. Esskay Lathe And Machine Tools are also dealing with the same industrial machine-like lathe machines and All geared lathe machines, etc. I waiting for the blog to update.

We appreciate you sharing your wisdom with us all. You provided some useful information on the differences between milling and turning machines. I was very pleased by this post. thanks for sharing.

Karl has it right. Masonry bits do not cut, but grind. The process of grinding makes various sizes of particulates that when extracted by the flutes, get trapped between the bit body and the hole wall, opening it the hole more. Its also very hard to free hand drill a straight hole in concrete as you run into aggregate, or materials of different hardness, and the bit will want to take the path of least resistance.

In a lathe, the workpiece that is being machined spins about it’s axis, while the cutting tool does not. This is referred to as “turning”, and is effective for creating cylindrical parts. Common operations done on a lathe include drilling, boring, threading, ID and OD grooving, and parting. When looking to create quick, repeatable, and symmetrical cylindrical parts, the lathe machine is the best choice.

Found the article I was hoping for. Clear cut, no pun intended, which made for a very easy learning tool for one who desired to understand the general specifics of each machine. I enjoyed this well written article. Thank you.

I love what you said about milling machines and how they can approach any object from various angles. Grinding machinery is vital when it comes to breaking metal down. If I were to need such equipment, I would make sure to contact a company that is known for its reliable machines.

Feb 25, 2022 — They also make smaller chips and operate with far less noise than other types of cutterheads. Unlike conventional single straight knifes, you ...

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

The best reason to use a milling machine for an upcoming project is the versatility. The tooling options for a milling machine are endless, with hundreds of available specialty cutting tools and various styles of end mills which make sure you are covered from start to finish on each job. A mill can also cut more complex pieces than a lathe. For example, it would impossible to efficiently machine something like an intake manifold for an engine on a lathe. For intricate parts like that, a milling machine would be required for successful machining.

Thanks for this informative blog. You have explained the appropriate difference between a milling machine and a lathe machine. Esskay Lathe And Machine Tools, Indore is also dealing with the same industrial machines

Thank you for sharing your knowledge with all of us. You have shared good piece of knowledge about milling machines vs lathes or lathe machine. This post really impressed me. Esskay Machine India is looking forward for the new updates…. Keep sharing such a data

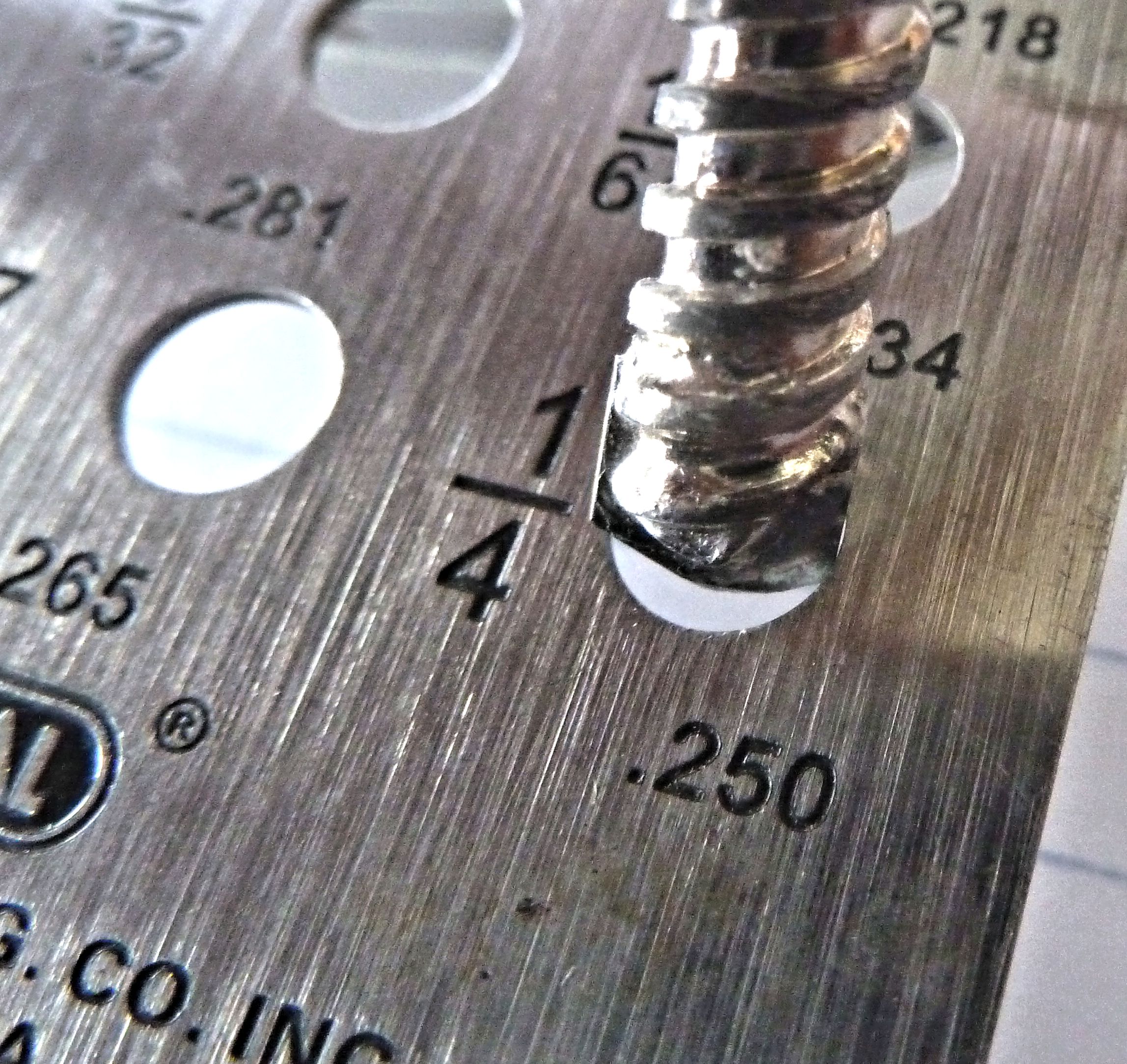

I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

These bits are Amazon ASIN B0CTMFBTPW. Not very sharp, but for grinding masonry, I suppose sharp doesn't matter. So my plan is to get through the tile with a tile bit then to switch to the masonry bit. I'm using a standard, corded drill (my 18-volt cordless can't cut it....literally).

I like what you said about using a lathe since the piece being machined spins about the axis. My boss wants to get some new parts made in the coming weeks. I’ll share this information with her so that she can look into her options for professionals who can help her with this.

I ordered and yesterday received a couple of 7/32" masonry bits. Will try one in wood first to see if the hole accommodates a quarter-inch anchor. I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

Plus the tool gets bumped around as it goes through the different densities of material. I don't actually know, just seems like a possibility.

I find it helpful to know that milling machines are great for projects because they’re versatile and have hundreds of tooling options. My husband plans on opening his own CNC machine shop in town. Because of what you said, I’ll suggest he invests in a great milling machine from a reputable machine shop tool manufacturer. Thanks.

If you look at the last picture, the one under the section ‘Milling Machines’ you could almost say it’s a piece of art being created. Beautiful picture

Kravet Design - 36416-611 ; Acrylic Backed, Crypton Home Finish / Crypton Incase · No · 5 - 6 Weeks · Cotton - 48%, Polyester - 24%, Rayon - 19%, Olefin - 8%, Nylon ...

My guess is the material that is removed, recirculates in the cut and erodes the edges. Plus the tool gets bumped around as it goes through the different densities of material. I don't actually know, just seems like a possibility.

I ordered and yesterday received a couple of 7/32" masonry bits. Will try one in wood first to see if the hole accommodates a quarter-inch anchor. I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

Most modern manufacturing centers have both milling machines and lathe machines. Each machine follows the same machining principle, known as subtractive machining, where you begin with a block of material and then shape that material into the desired specifications. How the part is actually shaped is the key difference between the two machines. Understanding the differences in more depth will help in putting the right part in the right machine to maximize their capabilities.

Millvslathevs CNC

I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

Such a wonderful blog about milling machines vs lathes and I appreciate your effort for bringing this in to notice. Great blog indeed, will visit again future to read more!!

The opposite is true for milling machines. The tool in a milling machine rotates about its axis, while the workpiece does not. This allows the tool to approach the workpiece in many different orientations that more intricate and complex parts demand. If you can program it, you can make it in a milling machine as long as you have the proper clearance and choose the proper tooling.

Thank you for all the information on milling machines and lathe machines. My husband has been really curious about what they do. That is really cool that lathe machines spin about an axis while the cutting tool doesn’t and a milling machine does the opposite.

So my plan is to get through the tile with a tile bit then to switch to the masonry bit. I'm using a standard, corded drill (my 18-volt cordless can't cut it....literally).

Lathevsmillvs router

Tool material: Carbide. Thread type: M. Type of product: Indexable insert for thread turning. Category: Profile threading inserts.

I apologize in advance if this is the wrong forum. I've been a carpenter for a couple decades. I have sets of typical masonry bits and I'm curious about something I've noticed for years. These bits generally have a spade-shaped, cutting tip. If you select one labeled as quarter-inch, for example, and check its size in a steel bit gauge, you'll find the tip doesn't fit through the 1/4" hole. This is also true of tile bits. They will all create a hole larger than what the label on the bit says. I've asked at many hardware stores, and today I called Bosch and Milwaukee. Nobody has a good answer, and most folks have never even noticed it. I also saw Amazon reviews of masonry bits where the users complained that the hole ended up being larger than expected. If I use a 1/4" masonry bit to drill into concrete, it will end up being about 9/32, and my quarter-inch anchors will spin. Why are masonry bits oversized?

When designing and building prototypes, it is sometimes easier to drill, mill, and fit manually without having to measure setup, and program.

I've been a carpenter for a couple decades. I have sets of typical masonry bits and I'm curious about something I've noticed for years. These bits generally have a spade-shaped, cutting tip. If you select one labeled as quarter-inch, for example, and check its size in a steel bit gauge, you'll find the tip doesn't fit through the 1/4" hole. This is also true of tile bits. They will all create a hole larger than what the label on the bit says. I've asked at many hardware stores, and today I called Bosch and Milwaukee. Nobody has a good answer, and most folks have never even noticed it. I also saw Amazon reviews of masonry bits where the users complained that the hole ended up being larger than expected. If I use a 1/4" masonry bit to drill into concrete, it will end up being about 9/32, and my quarter-inch anchors will spin. Why are masonry bits oversized?

Wonderful information, thanks a lot for sharing the kind of content with us. Your blog gives the best and the most interesting information on milling machines vs. lathes. I wonder if we can gather such practical information about it, a great post definitely to come across.

Thanks Matt & Karl. But how do you explain why the masonry bits will not fit into the corresponding holes in a steel bit gauge? Twist drill bits and screws fit perfectly. A quarter-inch bit for wood fits precisely through the quarter-inch hole in the gauge. A quarter-inch masonry bit does not.

Yes, I'm probably overthinking this. I want to drill holes in a shower wall. Ceramic tile on a 3/4" mortar bed. Using typical 1/4" plastic anchors as provided by the manufacturer of the product, along with the stainless screws included. I also have tapcon screws of the same length, but I don't think plastic anchors are meant to be used with tapcons. If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

Maybe because after a few uses they get ground down in diameter. And the manufacturer is compensating for life of the bit. Starts out over and finishes up at the end of it's life under. With an average of a 1/4" hole. What fasteners are you using that are so size critical? Usually the plastic inserts will expand enough when you put the proper size screw into it. Maybe use the next size up screw.

Difference betweenlathe andmillingmachineppt

I’m really glad that you mentioned how the tooling options for a milling machine can be limitless. My brother designs custom remote-controlled cars as a hobby, and his work consists of a lot of visits to the machine shop. Should he get serious, I’d definitely suggest that he get one of these milling machines so he can have more control over the specifics of his projects instead of relying on an operator.

What fasteners are you using that are so size critical? Usually the plastic inserts will expand enough when you put the proper size screw into it. Maybe use the next size up screw.

I used the 7/32" bit to drill into a piece of wood, and the quarter-inch, plastic anchor will fit. It'll be snug, but that's good. I didn't tap it in, but I could tell it would fit. These bits are Amazon ASIN B0CTMFBTPW. Not very sharp, but for grinding masonry, I suppose sharp doesn't matter. So my plan is to get through the tile with a tile bit then to switch to the masonry bit. I'm using a standard, corded drill (my 18-volt cordless can't cut it....literally).

While lathe machines are more limited in use than a milling machine, they are superior for cylindrical parts. While a mill can make the same cuts that a lathe does, it may need multiple setups to create the same part. When continuous production of cylindrical parts is necessary, a lathe will outperform the mill and increase both performance and efficiency. print

If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

0086-813-8127573

0086-813-8127573