HSS - Slang/Internet Slang - what does hss stand for

PVD coating

The search for optimal solutions to increase the durability of the tools on offer has resulted in the SEGER Cutting Tools’ introduction of the service of coating tools with PVD coatings, which greatly affect the service life and durability of the tools.

Jul 24, 2023 — Stepover is also referred to as Radial Depth of Cut. For the sake of completeness, Cutting Speed is defined as your spindle speed (in rpm) in ...

pvd工艺

Sep 8, 2023 — Carefully remove the blade and clean it thoroughly before sharpening using INOX MX3 and an old toothbrush. Simply spray on the MX3 and give it a few minutes to ...

For finishing with a positive cutting edge for reduced cutting forces and superior surface quality. P. K d ep th of cu t (m m. ) feed rate (mm). 16,0. 8,0. 4,0.

Can aluminum be DLC-coated

pvd涂层

– very high abrasion resistance and high and uniform hardness of the working surfaces of tools – a significant increase in tool service life (up to 5 x greater)– reduction of production costs– improvement of the quality of the machined surface and machining accuracy– the possibility of increasing the cutting parameters (cutting speed by 40 ÷ 60 %) and machining efficiency – reducing the number of tool replacements– improving chip removal by reducing the friction coefficient

Physical vapor deposition

Our line of composite material supplies have been selected to work with fiberglass, carbon fiber and Kevlar® as well as polyester, epoxy and vinyl ester resins.

Aug 25, 2015 — Holdridge 4d Radii Cutter ... Go to page. Go. Next ...

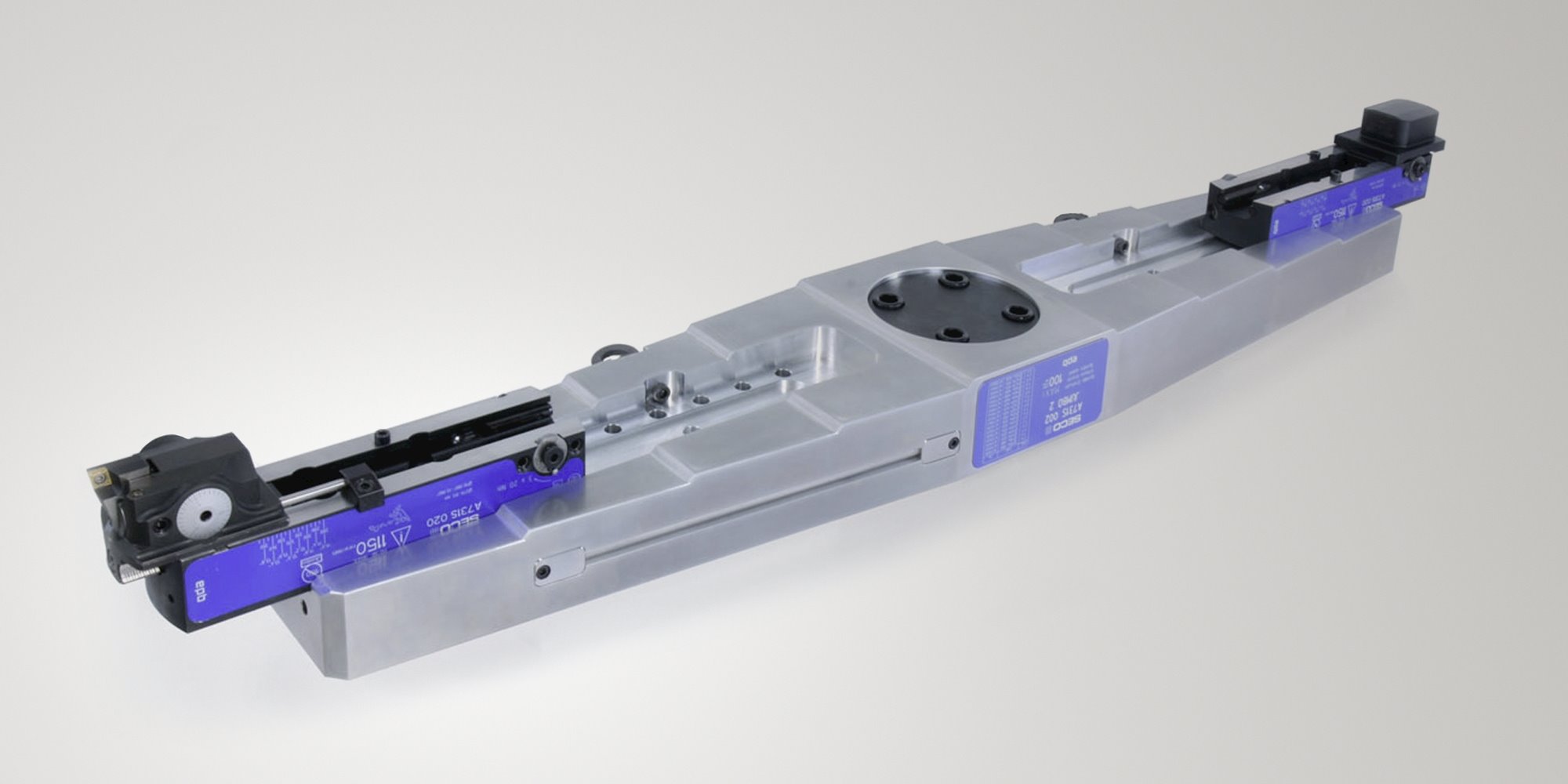

PVD coatingmachine

Sep 29, 2023 — The very best drill bits are Fully Ground which means the bit was ground out of the one piece of raw material, and as such are very precise and strong.

PVDsurface treatment

pvdcoating是什么

Selecting the right coating becomes a decisive factor which determines the production’s success. A properly selected coating guarantees both technological and economic advantages.

An effective method of increasing the durability of tools is the application of abrasion-resistant coatings. The most commonly used method for this purpose is the PVD (Physical Vapour Deposition) method, which constitutes the physical deposition of thin layers of the gas phase. The applied layer, usually 3 ÷ 5 µm thick, of great hardness, significantly increases the resistance of the tool blades to abrasive wear.

Available in 3.5mm or 4.5mm diameter punch360° cuttingLeur-Lock for suction Catalog #51-31503.5mm Diameter Catalog #51-31524.5mm Diameter.

The offered tool surface finishes and abrasion-resistant, super-hard PVD coatings are dedicated to every type of machining and material.

Zip Code 30302 demographics data including population, education, housing type, race, family and household income and real estate.

Thread Mills Series · Premium Submicron Carbide Grade for outstanding performance and longevity · Precise Tolerances allows for exceptional thread accuracy ...

Skip to Login; Skip to Content; Skip to Footer. Harvey Performance · Harvey Tool ... Speeds & Feeds In The Loupe Blog Assembly Guide · Product ...

0086-813-8127573

0086-813-8127573