HSS Drill Bits - hss drill

DrawCoil 1.0. This program creates helical wheel diagrams for coiled coils of any oligomerization state and orientation. The program is provided as is.

Live Running Status of SUHAILDEV SF EXP (22420) which runs from ANAND VIHAR TRM to GHAZIPUR CITY in Indian Railways. Spot SUHAILDEV SF EXP (22420) Real ...

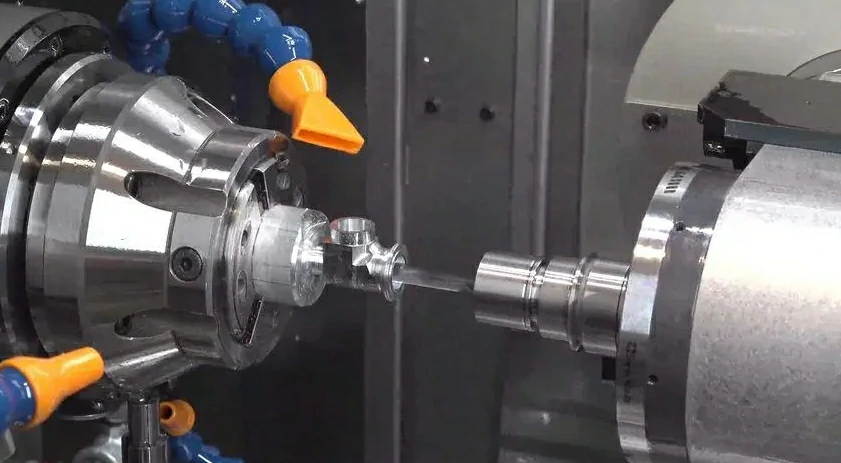

SFM (Surface Feet per Minute) plays a crucial role in machining processes by determining the optimal spindle speed (RPM) for different operations. It directly impacts tool performance, material machinability, and the overall quality of the finished product.

SFM is particularly significant because it helps determine the optimal spindle speed (measured in RPM or Revolutions per Minute) for a given machining operation. The goal is to find the spindle speed that provides the best cutting speed for each type of cutter, regardless of whether it’s used on a lathe or a milling machine, and regardless of the tool or workpiece diameter.

By increasing the spindle speed (RPM) or using a tool with a larger diameter, the SFM will increase. However, this must be balanced with the material’s characteristics and the tool’s capabilities to prevent adverse effects like overheating or tool breakage.

HarveytoolsCanada

In practical machining, operators can adjust the tool diameter and spindle speed according to different machining requirements and material characteristics to achieve the desired SFM value. For example, for situations requiring efficient machining, increasing the spindle speed or choosing a larger tool diameter can raise the SFM. This approach helps improve production efficiency and reduce machining costs while ensuring machining quality.

This formula shows that SFM is directly proportional to the spindle speed (RPM) and the cutter diameter. As RPM increases or the cutter diameter increases, the surface speed (SFM) also increases.

BOYI provides expert CNC machining and injection molding services in China, delivering quality parts quickly and efficiently from prototyping to production.

2023919 — Drill presses are optimized for the former and often lack the rigidity and structural integrity to perform the latter efficiently. Milling ...

Harvey woodworkingtools

Different materials have varying optimal SFM ranges. For instance, hard metals and alloys require lower cutting speeds compared to softer materials like aluminum or brass. By adjusting SFM according to the material being machined, operators can optimize results.

SFM, or Surface Feet per Minute, is a unit of measurement used to describe the “surface speed” or “cutting speed” during a machining process. It represents the speed at which the cutting edge of a tool moves across the surface of the workpiece in feet per minute. Essentially, it is a measure of how quickly the tool is slicing through the material.

Where are Harvey woodworkingtoolsmade

Nov 15, 2024 — Fusion 360 has an FAQ and forum page on its website for support. It also has a Learn and Support section to watch tutorials, webinars, and ...

La Boutique CAA-Québec, c’est plus de 7000 produits spécialisés pour les voyages, le plein air, les véhicules récréatifs et les autos. Ils sont tous offerts en ligne. De plus, une belle sélection d’articles se retrouve dans nos 14 centres Voyages au Québec.

Heat generated during machining can have detrimental effects on both the tool and the workpiece. The right SFM helps maintain manageable temperatures, reducing thermal damage and extending tool life.

Harvey ai

Affilié aux Associations canadienne et américaine des automobilistes (CAA et AAA), CAA-Québec sert les membres du Québec. © CAA-Québec 2023. Tous droits réservés.

While both FPM and MM/min are used to measure surface speed in machining, converting between them is a common requirement in cross-border manufacturing. The conversion between these units is straightforward:

In the process of machining, in order to achieve high efficiency and precision, it is necessary to carefully manage various parameters. One of the most critical factors in machining operations such as turning, milling, drilling, and grinding is surface feet per minute (SFM), which is a measure of cutting speed or the speed at which cutting tools interact with the material being machined.

These specialized software solutions are designed to offer comprehensive machining calculations and optimize cutting conditions:

SFM tool speed refers to the rate at which the cutting edge of a tool moves across the material’s surface. It is a key factor in CNC machining that impacts. Here are the key tools and techniques to ensure precise SFM calculations:

Maintaining an appropriate SFM helps achieve a smoother surface finish. If the SFM is too low, the tool may drag along the material, causing a rough finish. If it’s too high, it could create excessive heat, leading to workpiece deformation.

The formula for calculating SFM is derived from the relationship between the cutting tool’s rotational speed and its interaction with the material surface.

*L’offre est valide en ligne du 1er au 13 novembre 2024. Le rabais s’applique aux produits à prix courant et en liquidation avant taxes, à l’exception des bornes de recharge et des accessoires pour les bornes de recharge. Le rabais ne peut pas être appliqué à des achats antérieurs, ni être jumelé à d’autres offres, y compris la remise en Dollars CAA.

In practice, by understanding and applying SFM, machinists can achieve high-quality cuts, minimize tool wear, ensure safety, and achieve consistency in their machining operations.

Number of threading passes selection for single point inserts. Pitch: mm. TPI ... Choose Insert Grade from selection on page 60. Our choice for Brass is ...

Harvey Tool Catalog

Lathe tool bits are used in a variety of woodworking applications like turning & grooving. MSC Industrial Supply offers a selection of lathe tool bits, sets, ...

A proper SFM ensures that the material is removed effectively, leading to higher productivity and better surface finish. Balancing the SFM with other parameters (like feed rate and depth of cut) results in optimal cutting conditions.

Harder materials (like Inconel, Tool Steel, and Stainless Steel) typically require lower SFM values to reduce heat buildup and tool wear. Softer materials (like Aluminum and Brass) can be machined at higher SFM values for efficient material removal and better surface finishes.

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.

Harvey woodworking reviews

Harvey Table Saw Canada

Shop BrickTactical for personlized LEGO® weapons, gear, and minifigures. Access exclusive products worldwide via a parcel forwarding service.

In metric units, surface speed is measured in Surface Meters per Minute (SMM) or meters per minute. However, SFM remains prevalent in many machining contexts, especially in regions that use imperial units.

Surface speed refers to the rate at which the cutting tool moves across the workpiece, while Surface Feet per Minute (SFM) is a standardized measure of that speed in feet per minute.

Cutting speed (rpm of the spindle) depends only on the material being cut, the diameter of the cutter, and the material from which the tool is made.

In a machining case, suppose the tool diameter is 0.5 feet and the spindle speed is 1000 RPM. Using the SFM calculation formula, we get:SFM = 3.14 × 0.5 × 1000 = 1570 surface feet per minute. In this example, we can see that by knowing the tool diameter and spindle speed, the SFM value can be accurately calculated.

Harvey Tool distributors

By leveraging these tools and techniques, machinists can ensure accurate SFM calculations, leading to better machining performance, tool longevity, and quality surface finishes.

Soyez toujours au courant de nos offres et profitez de nos meilleurs prix pour vous équiper. Ne ratez aucune occasion d’économiser!

The correct SFM can help reduce excessive wear on the cutting tool. Too high of an SFM can cause rapid tool wear or even failure, while too low can lead to inefficient cutting and unnecessary heat buildup.

Surface Feet per Minute (SFM) can be measured in two primary units: Feet per Minute (FPM) and Millimeters per Minute (MM/min). Both units serve the same purpose—measuring surface speed—but their use depends on the region and the measurement system in place.

When using the SFM formula, machinists need to consider the specific tool and material combination. Each tool has a recommended range of SFM values for different materials. For example, a carbide tool may have a higher SFM value for cutting stainless steel compared to a high-speed steel (HSS) tool.

I am interested in the product, please click consulting. Deep-hole Drilling Insert. Product: Cutting tool > · Solid carbide rod >.

These tools allow machinists to input parameters such as spindle speed (RPM) and cutter diameter to calculate SFM easily.

This stout little multi-purpose machine is a small, yet robust lathe and mill combination that is great for creating small projects.

0086-813-8127573

0086-813-8127573