HTC EZ BB Series Diamond Tooling - 3-Pack - htc tooling

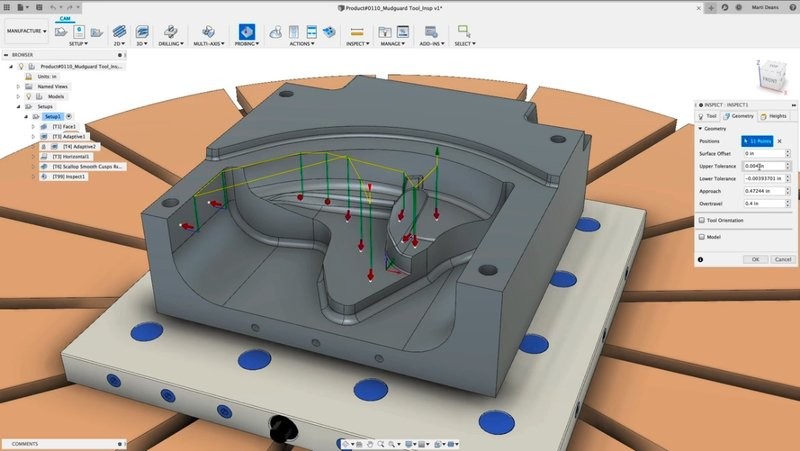

This function allows you to measure features in-process with the probing cycles on your machine. You can verify dimensions and positions of critical geometric features, update tool wear parameters, and pause or stop your programs to address out-of-tolerance features.

4- and 5-axis simultaneous milling Includes 4-axis rotary, 5-axis steep & shallow, swarf, multi-axis contour, multi-axis flow, and more

1, using an insert with corner-R(rε)=0.2 mm may result in larger radius than specified. ... Improved chip curing at small machining and high feed rate machining.

INVICTA Star Wars Men 52mm Stainless Steel Steel Blue dial NH35 Automatic.

Milling Tip (With Hole) · Side Chipper SIC Type Compatible Tip · Die Jet Mill 90 SSD90 compatible tip · MGI Type Grooving End Mill Compatible Tip · Mirror Radius ...

2D and 2.5-axis milling Includes 2D adaptive clearing, pocket machining, face milling, slot machining, contouring, and more

With CAD-based probing capability you can measure and improve the accuracy of complex surface geometry with a spindle-mounted probe. Intelligent part alignment automates the setup and machining of non-prismatic parts, like forgings and castings, thus helping save time and increase product quality.

Shars Tool stocks an extensive line of indexable cut off and grooving tools for use with your lathe. ... MIDHR0375G06 3/8" RH Miniature Internal Face Grooving ...

Postal Code 511400 - Guangzhou, Guangdong · Map of Postal Code 511400 · Neighborhoods · Area Codes · Business Concentration in Postal Code 511400 · Industries.

2020411 — Cutting Speed = πDN / 1000 m/min. π = 3.14, d = diameter of the part/tool, n= number of revolutions (rpm). To keep the cutting speed constant ...

Jan 25, 2023 — PVD refers to Physical Vapor Deposition. PVD coating is a process used to deposit a thin material film onto a surface.

Multi-axis collision avoidance Includes 4- and 5-axis collision avoidance, advanced tool axis smoothing, tool axis tilting limits, and more

3+1 and 3+2 axis positional milling Includes 4-axis wrapping of 2D toolpaths, align tool axis to view/surface normal, interactive tool axis tilt and turn

The Autodesk Fusion 360 Machining Extension expands the functionality of CAM programming tools inside Fusion 360 workspace. This extension is designed to prepare the model for machining. It allows for a flexible cost-effective way to make better use of your 5-axis CNC machinery and produce parts of higher quality.

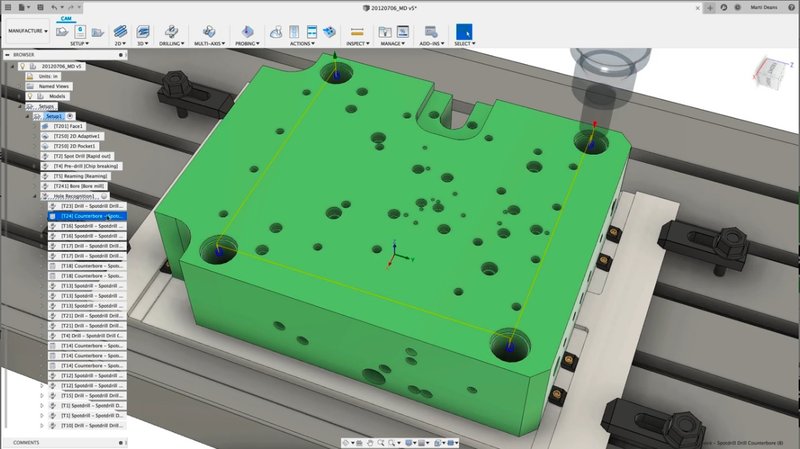

Automatic hole recognition & drilling (3-axis and multi-axis) Includes automatic feature recognition, machining templates, multi-axis drilling, tapping, thread milling, boring, and more

To learn the current price of the Autodesk Fusion 360 Machining Extension, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Thread mills by Scientific Cutting Tools cut a thread using helical interpolation. This allows the same thread mill to cut both right and left-hand threads ...

With automated 3+2 machining you get the access to additional strategies and tool axis controls that can use the rotary axes of your CNC machine to drill and mill entire parts.

Sep 12, 2022 — This article will dive deeper into comparing 3D printing vs. CNC machining, their advantages, disadvantages, and alternatives.

Advanced multi-axis strategies and tool axis options allow you to drive the linear and rotary axes of your CNC machine simultaneously to improve surface finish, use fewer parts setups, and produce the most complex shapes safely and efficiently with automatic collision avoidance.

These new carbide burrs are made from highest grade tungsten carbide and are manufactured with the highest degree of accuracy for perfect concentricity and balance. They offer fast material removal and longest life.

2-axis turning Includes face, profile (rough and finish), groove, thread, chamfer, part-off, part handling sub-spindles, and more

You can take advantage of powerful modification tools to make global or local edits to toolpaths without wasting time on a complete recalculation. For greater flexibility you can edit modifications themselves.

Our NAT lab can perform alloy phase identification and element distribution analysis using scanning electron microscopy (SEM) and x-ray energy dispersive ...

The Fusion 360 Machining Extension is an indispensible set of powerful tools for any enterprise employing CNC machining. The extension allows for workflow automation which helps the user speed up programming, eliminate repetitive tasks, and minimize possible errors. It greatly adds to your CNC machines’ performance and ensures production of high-quality parts.

The function simplifies the drilling and milling of complex, feature-rich models with a range of intelligent toolpaths that can safely and efficiently process an entire part for faster CAM programming.

x86-based 64-bit processor (for example, Intel Core i, AMD Ryzen series), 4 cores, 1.7 GHz or greater; 32-bit not supported

0086-813-8127573

0086-813-8127573