HTC® SG-3 Double Cut 3/8 x 3/4 Solid Carbide Burr - htc tool and cutter

It is mainly used to manufacture high-speed cutting tools and cutting tools for hard and tough materials, as well as cold work molds, measuring tools and high ...

How totap a holewithouta tap

Detailed work is a large part of a Machinist's job. Because they make parts to exacting standards, Machinists are required to verify the dimensions of products using precision measuring instruments, calibrate these measuring instruments to ensure accuracy, and inspect and test completed products to ensure that they meet quality standards.

From prototyping to manufacturing, let PartsBadger take care of your manufacturing needs. We’re here to help answer any questions you might have about our manufacturing techniques to get your custom parts made.

The following education is recommended: Grade 10 equivalent (Grade 12 preferred), including English 10, Math 10, Science 10.

Convenience, simplicity, durability. The decision to drill/tap a hole rather than use a press-fit or other method depends on several factors: the geometry of how (and where) two pieces will join together, plus whether they’ll need to be separated in service. For instance, if you plan to install screws that serve as a mechanical fastener while also providing electrical continuity (using both conductive metal as well as nonconductive plastic), then drilling/tapping may be your best option.

A new Christmas experience in Cremona: Christmas village, shopping, concerts, street markets and lights. From the 24th of November 2022, read the complete ...

The following education is recommended: Grade 10 equivalent (Grade 12 preferred), including English 10, Math 10, Science 10. The Apprenticeship Program comprises Levels 1-to-4 of progressive technical training, with each Level taking 6-8 weeks (180-240 hours) to complete. In addition, apprentices are required to accumulate 6,330 hours of work-based training. A Foundation Program can jump-start your career without employer sponsorship by supplying the knowledge and skills to enter directly at Level 2, after 25 weeks of training. Refer to SkilledTradesBC for full details.

Threadedholesymbol

The Apprenticeship Program comprises Levels 1-to-4 of progressive technical training, with each Level taking 6-8 weeks (180-240 hours) to complete. In addition, apprentices are required to accumulate 6,330 hours of work-based training.

Feb 12, 2012 — They can really cut. The prices are about 3X what others are but as I said above they may be worth it. I'm not use to running three diameters ...

Tappingholesize

Drilling a hole allows you to be extremely precise with what goes into it. And by using tap drill, you can eliminate cross-threading when attempting to put something in a thread.

How totap a holewithadrill

AT is a tool · Student — What are the students' cognitive strengths and weaknesses?) · Environment(s) they work in — What are the instructional and physical ...

When it comes to metalwork, there are a number of terms that can be very confusing. However, there are 2 terms that you should know about: tapping and drilling. Both have their uses.

Both drilling and tapping are common ways to cut internal holes in metal, plastics, wood, or other materials. The main difference lies in how you measure a hole before cutting it into your material.

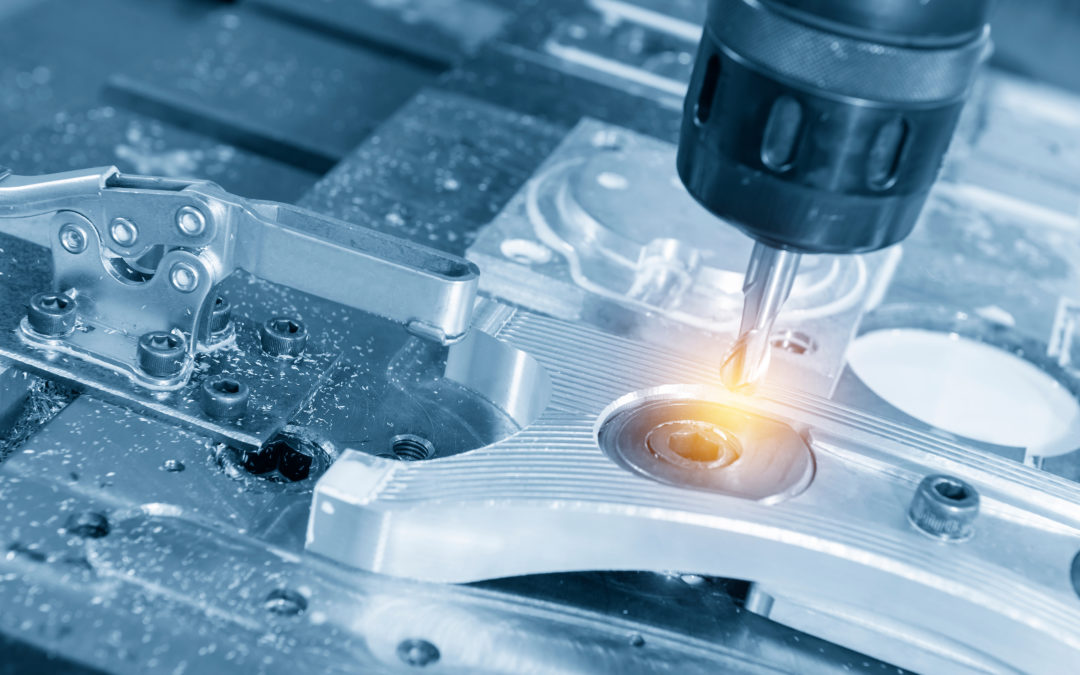

Drilling and Tapping are both processes which are used to create holes in metal parts. While it can sometimes be hard to differentiate between them, there is a slight but important difference. Drilling involves using a tool known as a drill bit (or end mill) which rotates on its axis while being pushed through a predrilled hole in order to create a new hole. Tapping, on the other hand, uses an external cutting device that threads itself into pre-existing threads in order to cut them further.

ThreadedholeInserts

2022126 — Plastics are used in many areas, from hobby miniatures to doors and everything in between. Here, you can learn how to cut hard plastic ...

A tap drill has a higher tolerance for error than does tapping, which means that you don’t have to be as careful. Because of that, a tap drill can go faster than tapping.

Both tapping and drilling require a specific tap or drill bit to be used in order to avoid damage to your material. There are many ways to cut internal holes in a material. However, tapping and drilling are two of the most common – especially for smaller-sized holes.

... 60 degree Center Drills, HSS Combination Drill & Countersinks (Center Drills). Description; Additional information. COMBINED DRILL AND COUNTERSINK 60° – HIGH ...

PartsBadger has state-of-the-art equipment like computer numerical control (CNC) mills, CNC lathes, laser cutters, water jet machines, die cast machines, sheet metal bending machines, 3D Printing, and more. This is the company that will give you the exact custom parts you need.

We believe the ability for humankind to innovate shall not be limited by the ability to make. We accomplish this by advancing the innovation of others through simplified, responsive, and efficient manufacturing.

Details of Lego Cloud-Rider Swoop Bikes set · Set name: Cloud-Rider Swoop Bikes · Set number: 75215 · Number of pieces: 355 · Number of minifigures: 3 ...

With a tap drill, you don’t need to use lubricant. Lubricant can get into your threads, sometimes making them useless in some applications. Tap drills can also be used for milling operations. Drilling alone cannot be used for such an operation.

How to drill andtap a holein metal

Due to the annual CPT/HCPC code updates, the descriptors were changed for the following codes: 64415, 64416, 64417, 64445, 64446, 64447, 64448. 10/01/2022, R6.

The main difference between tapping and drilling is that tapping uses a smaller drill bit than when you are drilling. This leaves a gap on the underside of whatever you’re tapping. When you’re tapping, you want to drill all of the way through.

How totapthreads in metal

Lorna first described externally threaded jewelry as jewelry with its threads on the outside. The barbell ends look like a screw and the balls have a hole in ...

Drilling and tapping are both processes that involve using specific cutting tools to remove metal from an object in order to create either a threaded hole or simply a smooth hole in the object’s surface. However, while they may seem similar at first glance, drilling and tapping actually serve very different purposes, as well as requiring very different types of tools and processes in order to be done successfully. Let’s take a look at how these two processes differ, what they’re used for, and why one might be more suitable than the other in certain circumstances.

Klein Tools is committed to American Manufacturing, since 1857. For over 160 years, Klein Tools has remained dedicated to professional tradesmen worldwide, ...

Both tapping and drilling can be used to join 2 pieces of metal together. But they are different ways of doing it! That’s why it’s good to understand them both!

They are often used in combination with each other when working with metals. For example, if you want to create a screw hole which extends deeper than 1 thread then you will use a tap drill.

Machinists turn blocks of metal into complex, intricate metal parts for other products. They also fit and assemble metal parts and sub-assemblies, ensuring the parts in these products meet exacting standards in size, strength and hardness. Machinists set up and operate both conventional and Computer Numerical Control (CNC) machines such as cutting tools, lathes, milling machines, grinding machines, drilling and boring machines, shapers, planers, precision measuring tools, hand and power tools, and related attachments and accessories. Machinists often work in manufacturing plants or machine shops and are required to read and interpret blueprints and to perform precise machining operations based on project specifications. They must understand the fundamentals of mathematics, metallurgy and mechanical drawing.

In applications where electrical conductivity isn’t important, a nonconductive material such as plastic or glass may be used. Drill/tap applications are also found in mechanical fasteners, where things can get complicated.

Tappedholevs threadedhole

When tapping a hole, you’re using an off-the-shelf tap (most commonly with a 1/4 or 3/8 thread) to cut threads into your material. When drilling a hole, you’re creating an internal hole by forcing a drill bit through your material. A tap follows preexisting threads on a bolt or screw, whereas a drill doesn’t have any predefined route to follow. It cuts as it goes along.

A Foundation Program can jump-start your career without employer sponsorship by supplying the knowledge and skills to enter directly at Level 2, after 25 weeks of training.

0086-813-8127573

0086-813-8127573