Husqvarna Carburettor Adjustment Screwdriver - 5mm / 20T - spline carb tool

Cuttingspeedformula

The SFM is used to calculate the RPM of the spindle and workpiece. RPM is based on the material being cut, the material of the cutting tool and the diameter of the material being cut.

Setting the lathe to use the correct speed (spindle RPM) for the operation is important. Determining the correct RPM takes a combination of research, observation and common sense.

When using the parting off tool, set the RPM to about 1/4 of the calculated value. When drilling, calculate the RPM based on the drill bit diameter, rather than the workpiece size.

Lathe cuttingspeed chartPDF

When it is time to start cutting, turn the spindle speed to a low number and start the spindle. Slowly turn up the speed until the readout is close to the calculated RPM.

Common materials have a calculated value, called surface feet per minute or SFM, for the maximum speed that a tool can move through the material, without excessive wear or damage.

Cuttingspeed chart

If you have questions about ordering, or require any other assistance or information, please don't hesitate to reach out. We welcome your contact, and are always happy to be of assistance.

Spindle speedformula

Note: Observation and common sense will also help determine the correct speed. For example, if the tool is chattering and making lots of noise, something is wrong. Stop, look at the cutting tool, recalculate the speeds, and ask Shop Staff for help if needed. If the formula calculates an extremely high RPM, perhaps your math isn't correct. If you have questions about the RPM, see Shop Staff for help.

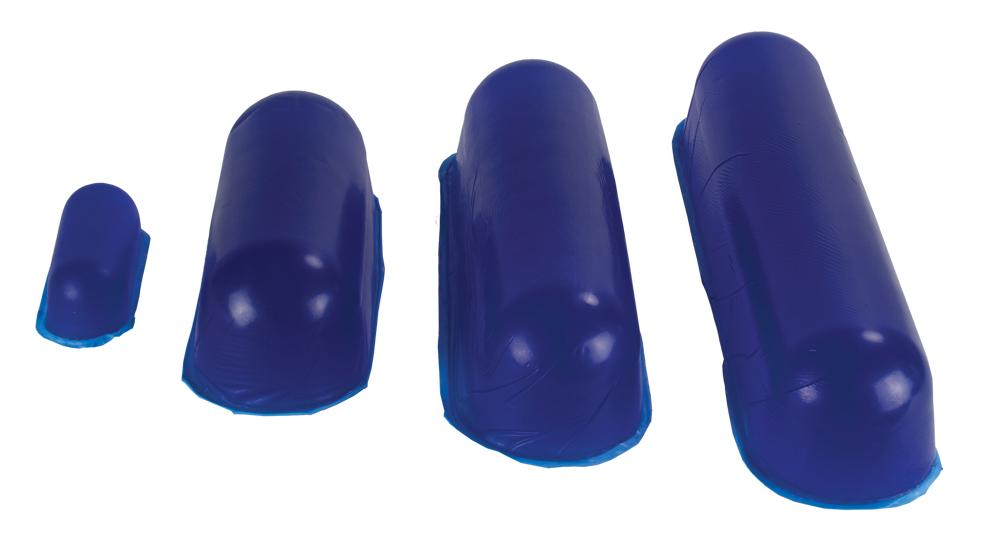

The Standard Flat Bottom Chest roll is a highly versatile positioner that is ideal for a variety of positions and procedures. Place under torso to allow for chest expansion or place under feet to protect from possible nerve damage in prone. May also be used in supine under knees and lateral on each side of patient to keep them in position. Flat bottom provides stability and keeps positioner in place.

0086-813-8127573

0086-813-8127573