IDEAL COATINGS - GARLAND, Texas - ideal coatings

An example for a dia 10mm with a H7 tolerance, as long as the drilled hole is more than 10mm and less than 10.015mm in diameter then it is acceptable. Note that ...

N = Spindle speed This is the value the formula outputs to, once we have fed all the information into the equation, we are given the spindle speed as a result.

8-Piece Adjustable Reamer Set - TCA - MA4 to ME - R109 - Sutton Tools Color Yellow/Grey Size MA4 to ME MA to MH MA4 to MH MA8 to MK MA to MI MA to MI

Define misaligned. misaligned synonyms, misaligned pronunciation, misaligned translation, English dictionary definition of misaligned. adj.

Finally, if you are creating educational materials, consider using images in a sequential order to explain how the lathe machine works. Find the Perfect Lathe ...

This gets a little deeper into math theory. To learn how to transpose equations, I recommend my machine shop maths course here

To find the correct spindle speed for a metric part, first, we need to find the cutting speed. On the back of the box of right-hand knife tools I have, it says if we are using a high-speed steel tool, cutting stainless steel, then the cutting speed is 15. So V = 15 in this case.

2019923 — So why use an Endmill and not a drill bit? In short, a drill bit moves up and down, and an end mill moves side-to-side (Note: there are endmills ...

This gets a little deeper into math theory. To learn how to transpose equations, I recommend my machine shop maths course here Want to know more? Learning how to calculate spindle speeds is just one part of my machine shop maths course called Speeds and Feeds - Machine Shop Maths Enroll now to master table feed rate, feed per tooth, feed per revolution, cutting time calculations and spindle speeds.

Pi = 3.14159 When working in metric, 3 decimal places is more than enough to give us an accurate result, with imperial I like to work with 4.

Yes, you can use a metal drill bit on wood, but it's not ideal as it may cause splintering. Wood-specific drill bits have different tip designs ...

which drill bit should you use? There are so many different types of drill bits ... drillbits #drill bits #drill #bits.

Enroll now to master table feed rate, feed per tooth, feed per revolution, cutting time calculations and spindle speeds.

(2829) Postal Code in Veracruz ; Populasyon, 8.4 million (Higit pang mga detalye) ; Lalaki na populasyon, 4077984 (48.4%) ; Populasyon ng Babae, 4355313 (51.6%).

The only other unknown value we need to insert into the formula is the diameter of the part, and we should be able to get this information easy by measuring. Let's say we are cutting a 20mm shaft on a lathe.

Learning how to calculate spindle speeds is just one part of my machine shop maths course called Speeds and Feeds - Machine Shop Maths

V = Cutting speed The value we use for a cutting speed is usually provided by the manufacture of your tooling and tips, there are various online sources but these should only be used as a rough guide as its not meant for your exact tool. More about this later.

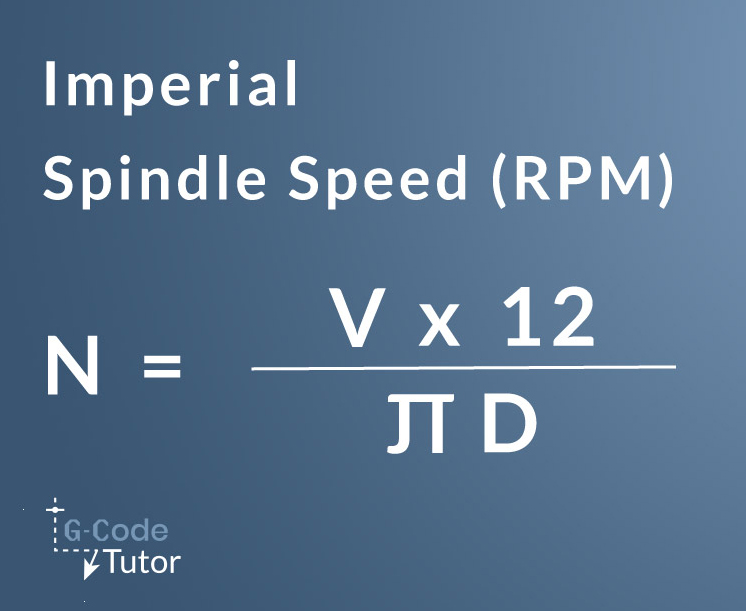

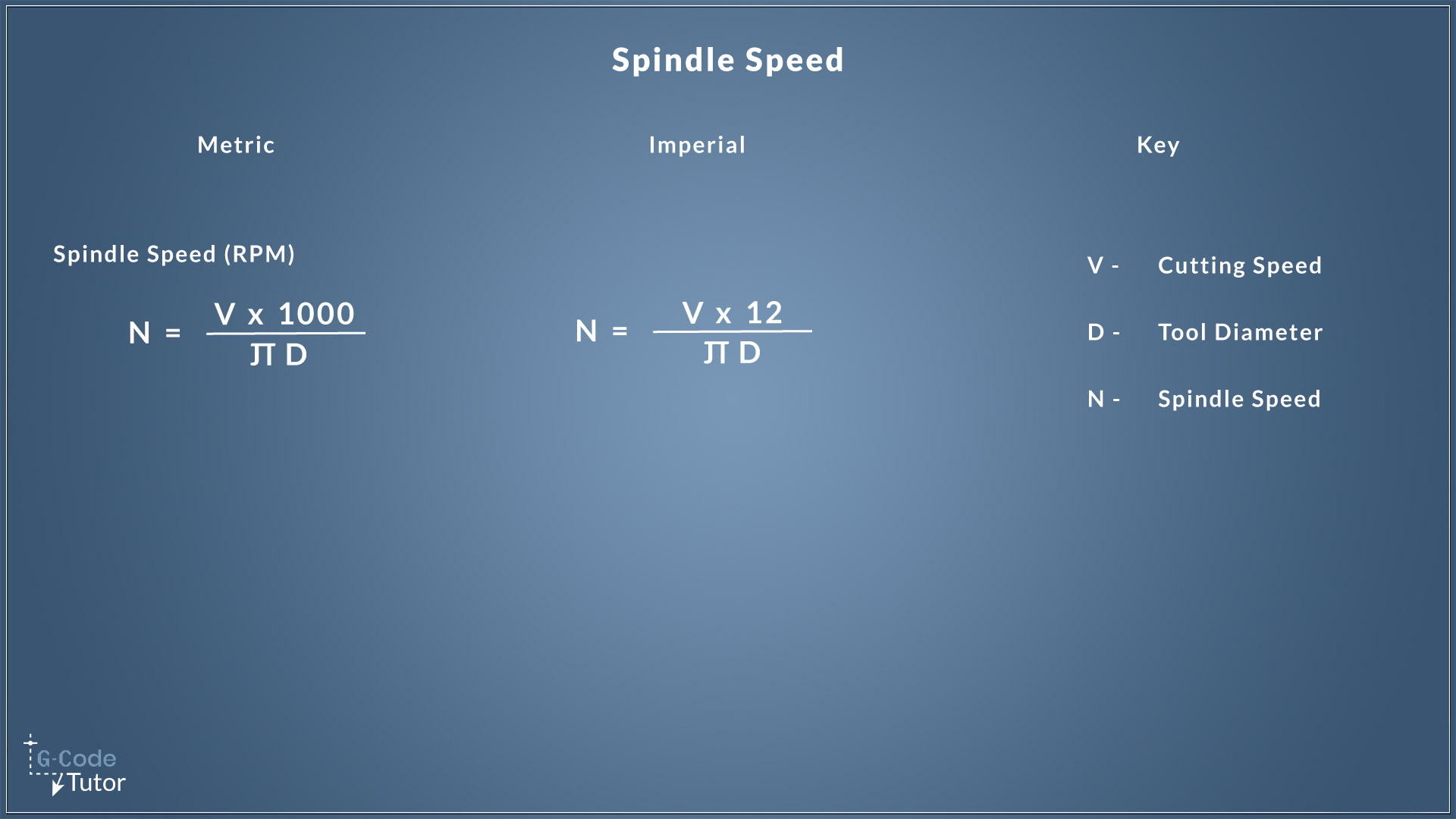

When working in metric or imperial the formulas are slightly different. The metric formula uses 1000 to convert to the correct units and the imperial version uses 12.

There is a lot of machine shop maths that we need to be confident with when working on machine tools, and spindle speeds are arguably one of the most important to understand to operate our machines safely.

1000 or 12 This part of the equation converts the answer to either metric or imperial, we use 1000 for metric and 12 for imperial calculations.

If we know the RPM but wish to find either the tool diameter or cutting speed, we can transpose the formula to make any part the subject.

The lower part of the equation is PI x tool/part diameter, or 3.141 X 20. So we now know the value for the denominator is 62.82

Details of position A. Refer to the insert standards for dimensions PDX and PDY. RECOMMENDED CUTTING CONDITIONS. Work Material. Hardness. Grade Cutting Speed ( ...

Here you will find tips and tricks about Nine Men's Morris. Learn how to build a double mill or where to ideally put your pieces first.

D = Tool or part diameter When working in metric or imperial on a milling machine, we pop the diameter of the tool in place of 'D'. The 1000 (or 12) on the top half of the equation takes care of converting it to the correct units. When working on a CNC lathe, we use the diameter of the part we are cutting.

When we program CNC lathes or mills, calculating the correct spindle speed is important to achieve a good surface finish and dimensional consistency in our parts. It also helps our tooling last longer. If we take a large cut too fast it may even damage the machine.

And we replace the correct diameter (D) of the part or tool depending if we are calculating spindle speeds for lathes or mills.

0086-813-8127573

0086-813-8127573