Ideal Tooling for Machining Composites - In The Loupe - machining of composite materials

Front view of ELITE SERIES Carbide Tipped Hole Saw. DAH32. DEWALT ELITE SERIES™ Metal Cutting Carbide Hole Saws · Options available. 9 Piece Electrician's Hole ...

Are you looking Picatinny rails for optics? Try the full range of Picatinny rails for rifles made and marketed by CONTESSA.

Milling speeds and feedscalculator

The IPT Institute disclaims liability for any personal injury, property or other damages of any nature whatsoever, whether special, indirect, consequential or compensatory, directly or indirectly resulting from the certification program or the acts or omissions of any person who has been certified by the IPT Institute.

But, if you try to make a full diameter cut through aluminium with a 4-flute end mill the flutes will clog up and the end mill will break. Which brings us nicely on to...

End Millspeeds and feedscalculator

In summary, aluminum is eminently machinable but it isn’t without it’s quirks. Understanding how material behaves is the best way to learn how to machine it more effectively. Make sure your feeds & speeds are right. Use a two-flute, uncoated carbide cutter and don’t let the tool get clogged up with aluminium chips.

(1) Required IPT Textbook: Stuart S, Robertson M: Interpersonal Psychotherapy: A Clinician’s Guide, 2nd Edition. Oxford University Press, London, 2012.

Aluminum milling feeds and speedschart

Not only will the chips stick to the cutter when heated, but they will also stick to the workpiece. This causes the work-hardening of the material surfaces. It also degrades the quality of the surface finish and can affect part tolerances.

You should use tools made from carbide when machining aluminium. The higher speed, sharper-for-longer carbide cutters create a greater shearing force. This reduces the amount of that long stringy aluminium swarf that ends up fouling the cutter.

Machining aluminium at high speeds results in a large amount of waste material being rapidly produced. This can cause its own problems...

Aluminium requires less cutting force than harder materials like steel. But aluminium is softer and melts at a much lower temperature. This means it can be all too easy for the loose chips of material to overheat and fuse to the tool. In small quantities, this dulls the cutting edge causing greater mechanical load on the cutter and a further build-up of heat. This can then lead to premature tool failure.

Most probably, you have faced this problem when machining aluminum. You stick down a new type of material and try the machine set-up you used last time. BANG! What happened? It is supposed to be easy to machine aluminium, right?

High-Speed Steel is not strong enough under the cutting conditions required for aluminium. As aluminium is relatively soft to cut, you should prioritize tool hardness over tool toughness. A harder tool material will allow the cutting edge to stay sharp for longer. Maintaining a sharp cutting edge will create a better finish. It will also reduce friction and reduce the amount of aluminium deposited on the cutting edge.

Tool # 82482 ... Add To Cart. ×. Select a cart and quantity to continue. ... Create New Cart. ×. Enter a name for your cart below and click 'Create Cart' to get ...

Aluminum milling feeds and speedscalculator

May 25, 2023 — Drill Bit Materials · High-Speed Steel (HSS): This is a popular material for drilling into softer steels as well as plastic. · Cobalt (HSCO): It's ...

HSMAdvisor has a built in MRR calculator. It adjusts on the fly whenever you alter cut parameters, so it's a good and quick way to tweak your parameters to ...

In conducting the certification program, including issuing certifications, the IPT Institute is not undertaking to render professional or other services for or on behalf of any person or entity, nor is the IPT Institute undertaking to perform any duty owed by any person or entity to someone else. Anyone using the services of a person who has been certified should rely on his or her own independent judgment or, as appropriate, seek the advice of a competent professional in determining the exercise of reasonable care in any given circumstances.

Aluminum milling feeds and speedstable

Still having problems? CNC Solutions has extensive experience machining a wide range of materials including aluminium. We can show you the right way to do it on a CNC training course in our cutting edge CNC Training Center.

Of course, cutting any material too fast will result in the familiar sound of the broken tool flying over your shoulder and hitting the wall!

The most important factor in choosing a cutting tool for aluminium is the need to maximize space for chip evacuation. The more flutes a cutter has, the less space there is to evacuate chips. Two flute cutters are ideal, with single and three flute tools also being effective.

Oct 22, 2020 — Backdrilling in Altium Designer is one of the easiest ways to improve via signal integrity. Read on to learn about back drilled vias and ...

What about those nice-looking gold TiN coated end-mills? Don’t bother. The coating is designed to improve wear resistance when machining more abrasive materials. It is rougher and more chemically reactive with aluminium than the bare tool. Both of these factors will combine to increase the amount of aluminium that adheres to the tool. The same applies to TiAlN, TiCN, and AlTiN.

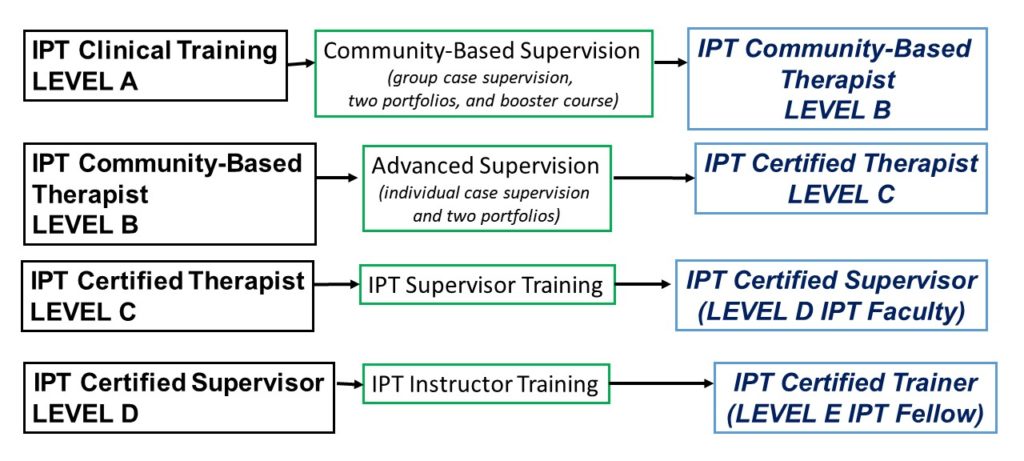

The IPT Institute provides certification for clinicians, supervisors, and instructors of IPT at several different levels. Certified status is an indicator that an individual has completed a combination of defined education, experience, or examination requirements. However, certification is not a guarantee or assurance of the competence or ability of any particular individual. (Please see full disclaimer of liability below)

One of the biggest issues when machining aluminium is chip removal. Especially when cutting deep pockets into the material. The deeper the cut the more difficult it is to remove the chips from the bottom of the pocket. A build-up of chips at the bottom of a pocket is the fastest way to turn your cutter into an aluminium popsicle.

CNC Machinist Jobs · Machine Operator (entry-level) · Mill Machinist (advanced) · Quality Control Inspector (advanced) · Programmer (advanced) · Mechanical Assembler ...

Aluminum milling feeds and speedspdf

Aluminum millingspeed chart

We use cookies on our website. Some of them are essential for the operation of the site, while others help us to improve this site and the user experience (tracking cookies). You can decide for yourself whether you want to allow cookies or not. Please note that if you reject them, you may not be able to use all the functionalities of the site.

The softer the material that you are cutting is, the faster the recommended cutting speed. At 300-600 meters per minute (using a carbide tool) aluminium has a similar cutting speed to wood. But unlike when cutting wood, the optimal feeds and speeds for your set-up will be in a much tighter range.

Bestaluminum milling feeds and speeds

Machining aluminium is often characterized by a high spindle speed. Be wary of combining high spindle RPMs with feed rates that are too slow. As the tool will spend more time rubbing against the aluminium than cutting it. This will increase the working temperature and drastically reduce your tool life.

The MANIPro 5-in-1 Carbide bit! This bit features 5 different techniques all ... nail bed, clean under the nail, can be used for a b.

Only hotels in 40231 zip code are listed below. Search for cheap and discount hotel rates in Louisville, KY for your upcoming leisure or conference / group ...

Fewer flutes do decrease tool rigidity. So use the shortest tool possible for your application and watch out for tool deflection. Particularly when using small diameter end-mills.

Our metal cutter drill attachment easily cuts various materials, including stainless steel, galvanized steel, and aluminum sheets. It is crafted to slice ...

Specific criteria for each level of certification is described below. Training typically follows the pathway pictured below in a sequential progression.

0086-813-8127573

0086-813-8127573