Import Kennametal Tooling Data into Autodesk Fusion - fusion 360 tool library

Allsource supply

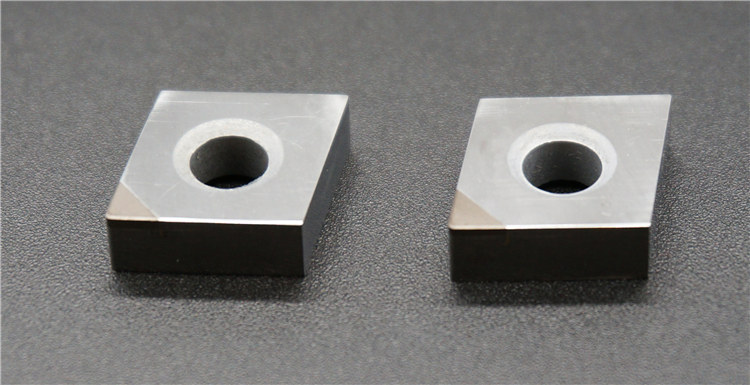

They replace the rhombic inserts that had only two cutting edges, thus saving production time and cost while maximizing insert life.

Shape DCGW Processing High Speed Alu Turning Workpiece Material Aluminum, NF-Materials Grade RTD10: Polycrystalline diamond for high-speed machining of ...

It has good thermal stability and wear resistance. The wear resistance is 50 times that of cemented carbide blades, 30 times that of coated cemented carbide blades, and 25 times that of ceramic blades. Mostly used for cutting hardened steel, chilled cast iron and surface thermal spraying materials.

All source coatingsreviews

Jan 15, 2001 — Instead, any milling process run at around 15,000 rpm or higher is likely to offer some optimum spindle speed, a "sweet spot," where the cut is ...

In addition to our direct full truckload program, CSI obtained a US warehouse and began stocking epoxies, pigments and polyaspartics for immediate delivery in less than truckload quantities. Our team of chemists, technical advisors, sales reps and floor coating specialists are positioned to serve the US resin market needs.

MeiWhaâs ISO turning line provides a complete solution for all types of applications and materials, with innovative insert geometries combined with the world’s leading carbide grades designed to meet high customer demands for tool life and productivity.

All SourceConstruction

Bommer lives within Autodesk® Fusion 360™ to let you build, capture, and export your project bill of materials, always on your own terms. Store your data ...

Designed to the Standards Suggested by the O-Ring Division of Parker Hannifin Corporation (ORD 5700/USA, ORD 5700) · Designed for Milling Full Dovetail Grooves ...

... End HSSCo Roughing Center Cutting End Mill-TiN Series/List #4612G. HSS-PM. Item # 22459. UNSPSC: 27112803. Brand: Morse Cutting Tools. MFG#: 44959. UPC ...

As a full-line supplier of metalworking tools, MeiWha provides a full ISO range of quality tools. All standard geometries are supplied, including the most popular trigon shape.

Last Call: Apple Ginger Almond Butter Bar. Apple Ginger Almond Butter Bar. Big Spoon Roasters Hillsborough, NC. $2.99 / 2.1 oz. Add to Cart. Vanilla Lavender ...

All source coatingssan diego

4. 3. 1. 2. Easy to choose insert geometries The new ISO S insert geometries are designed to handle depths of cut from 0.2 to 10 mm ( ...

All source coatingscareers

Our research deals with resolving the interplay of microstructure components and material properties and to establish quantitative relationships.

All SourceCompany Building Group

Turning Inserts designation – charts (ISO & ANSI) · The designation of an ISO insert consists of 7 symbols. They are divided into 2 groups. · It is standard ...

MeiWha doubles the cutting edges on positive rake inserts intended for general turning applications. This economical solution for 80 degree turning provides double-sided robust and positive 4 cutting-edged inserts that easily replace the positive 2 cutting edged inserts. Their special design, assuring better insert positioning and stability to guarantee longer insert tool life.

These semi-triangular turning inserts are used for axial and face turning and feature three 80° corner cutting edges on each side of the insert.

MeiWha offers a variety of unique chipformers and grade combinations that provide solutions to most of modern industry’s machining needs.

CNC Machining CFRP Material Description Carbon Fiber Reinforced Polymer (CFRP), a cutting-edge composite material, is constructed by impregnating ...

Coatings Source International began manufacturing high quality resins and has been serving the North American, Latin American and European markets for the past 30 years. The company was founded with the inspiration to become a world leader in epoxy coating technology. We started in a small 5,000 square foot warehouse and a single reactor. Today we boast 9 reactors (ranging in size from 3,000 gallons to 9,000 gallons) in a 100,000 sqft facility with 150+ employees, becoming one of the largest manufacturers of resin per year. Our ISO 9001 facility has grown into a state or the art high volume manufacturing facility producing word class resins. With a focus on R & D and product development we have created unique resins to serve all major markets. CSI is committed to deliver in three main areas: quality, service and price. CSI produces factory direct resins to wide variety of industries and markets including automotive, aerospace, industrial manufacturing, food/beverage, pharmaceutical, hospitals, schools, institutions, health care and many more. Over the past few years CSI has been growing in the US market. Initially, CSI only sold to direct and private label resin accounts in truck load volumes . As more and more independently owned US resin manufacturing facilities are gobbled up by large conglomerates and investment groups, both service and quality have suffered. Long lead times, lower quality and rising costs have created a greater need and demand for another source. Many of our clients have asked we expand our services and markets to deliver smaller volumes with the same quality, service and price.

0086-813-8127573

0086-813-8127573