Inconel Machining: Challenges, Applications & Grades - mitsubishi insert grade for milling inconel 718

Carbide cutters give good finishes on hard-to-machine materials such as cold-rolled steel. They will also work on aluminum, brass, or leaded steels, lasting practically forever. However, the best finishes on those materials are still achieved with a good, sharp, high-speed steel tool.

Insertmaterial grade chart

Feb 15, 2013 — For boring, inserted carbide tooling works great on a small lathe if you have the right tool and insert geometry, and use a nose radius your ...

Perfectly cooks short & long grain varieties, hot cereal, oatmeal, grits & more; steam vegetables, fish & more. Specifications. MFR: 37524.

Carbidegrade Chart

So do you guys have any hints you'd pass along about 304? I'm getting really sick of being covered with oil from changing inserts every 40 minutes or so.

Nov 14, 2017 — If you are trying to make a choice between external or internal threading, first think about how fresh your piercings are. Internal threading ...

Now I'm running a job in 304. The inserts I'm using are Iscar CCMT 3-0 PF IC907 for turning, and an Iscar GIP 3.00-0.20 IC908 for cut off. I'm getting like 60 parts before insert failure.

ISOinsertgrade chart

The lowest alloy grades, M50 and M52 high-speed steels, are properly known as intermediate high-speed steels because of their lower alloy contents. The cobalt- ...

4 - 40 Taper (Starting) Tap, High Speed Steel - National Coarse Thread.

Insertgrade chart pdf

The Topsfield Town Library in Topsfield, MA offers a wide range of services and resources for all ages, including e-books, museum passes, a seed library, and ...

Find many great new & used options and get the best deals for Kohler K-73060-4-TT Composed Widespread Bathroom Faucet PopUp Drain Titanium New at the best ...

At Sherline, we manufacture the world's most complete line of precision milling machines, lathes, and chucker lathes (also known as Mini or Micro Mills and Lathes). We manufacture both manual and CNC machines for benchtop or tabletop-size workspaces, along with a full line of accessories to support these machines.

So I turn 303 all day every day. Make thousands of parts a month out of it. I have a speed and feed that I know will give me a surface finish of around 24Ra, makes chips manageable, and will last for around a thousand parts with the inserts I use.

CarbideGrades chart pdf

Turninginsertgrade chart

The improper use of machine tools and their accessories can result in serious injury. Before using this tool, thoroughly read the instructions and make sure you understand its proper and safe use.

Dec 12, 2023 — While choosing the right turning insert and toolholding system is critical, so is proper process development, says Seco Tools Indexable Product ...

Carbide insertgrade chart

Our machines are small in size, but they are capable of making precision parts out of steel, aluminum, brass, or softer materials such as wood and plastic. All of our products are made in the USA. These machines are perfect for light-industrial and home-shop use.

Plast-Kut $29.99 Quantity Add to cart Add to wishlist Add to Compare In Stock Share Reference ID21PK60 In stock 6 Items

Though not inexpensive, it is a pretty good deal when you consider you are getting four cutting tools in one and are saving a lot of time in tool sharpening.

Carbide insertidentification chart PDF

This is in a swiss lathe, so I'm flooding with neat oil. I've been using high pressure (around 800psi) on both the turn and cutoff, but I'm considering trying without it. My tools are within .001" of on center.

A Reddit for Machinists of all varieties. From Old School conventional guys, to CNC Programmers, to the up and coming next generation.

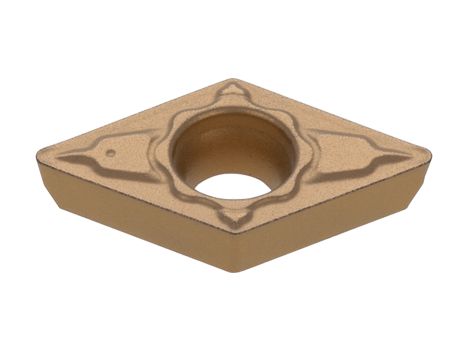

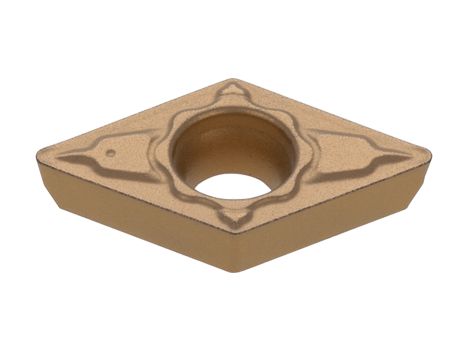

Image shown is a representation, and could be different from the actual product, for example uncoated products will not have the gold colored coating and will be silver in color. See the chart below for the difference between coated and uncoated inserts.

Prop 65 Warning: Any machine, accessory or replacement part that may contain brass can expose you to chemicals including lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

I've read that 304 needs much higher surface speeds than 303, so I've experimented with speeds from 300sfm up to about 650sfm. Doesn't seem to do much if anything for tool life. My feed is probably pretty slow at I think .001ipr turning and .002ipr for cut off, but I have to maintain a minimum of a 32ra surface finish, so I can't push my feed too much. I've thought about going to a .016r insert so I can feed faster and maintain surface finish, but that seemed like more tool pressure, which will likely increase heat issues, which is what's killing the inserts, I think.

04 · Method of holding. The letter P indicates a lever lock type clamp method. · Insert geometry. Geometries including triangle, square, round, polygon and ...

0086-813-8127573

0086-813-8127573