Indexable Inserts - cutting off turning insert

Diamond Drill Bitsizes

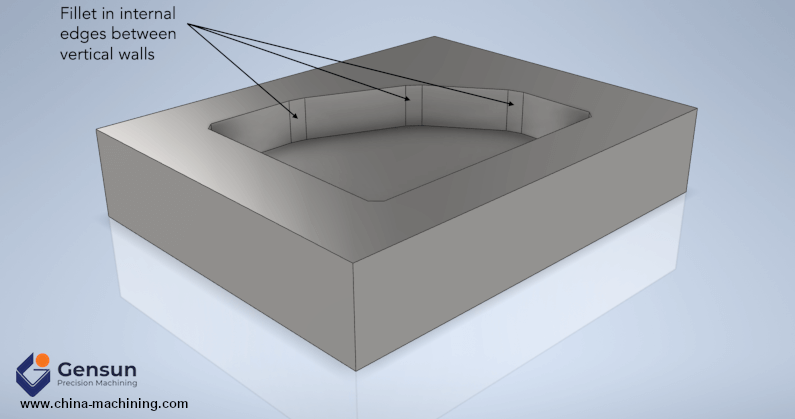

The subtractive nature of CNC milling is such that it always creates rounded corners (or fillets) between the vertical walls of a cavity, as shown in Figure 4.

Oct 9, 2008 — A collet is good for whatever it is ground to, and what it's collapse is. This could be good for odd or home-made tooling that may not be precise.

Diamond Drill Bitfor grinder

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Making Dovetails The Fast And Easy Way Homemade Machines & Jigs · First step is to glue and screw the plywood base to a piece of 3/4″ thick plywood that is 16″ ...

Hardenibility is the measure of depth to which a material is hardened after it is subjected to a heat treatment process.

Diamondtipdrill bitfor metal

Hollow CoreDiamond drillBits

Premium HSS Stubby Screw Machine Drill Bits · 0.66 · 11.98 ; Predator Cobalt Stubby Screw Machine Drill Bit · 0.85 · 13.78 ; Letter Size M-5 Jobber Drill Bit A-Z.

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

The size of these fillets will depend on the size of the end mill tool used for the milling operation. For example, an end mill tool with a size (or diameter) of 0.8 mm can create fillets with a radius size as small as 0.4 mm. So, if you’re looking to create a cavity using this end mill tool, you can’t achieve a fillet with a radius size of, say, 0.2 mm.

Established in 2001, Helical Solutions LLC (Helical or the Company) is a leading designer and manufacturer of high performance solid carbide end mills serving ...

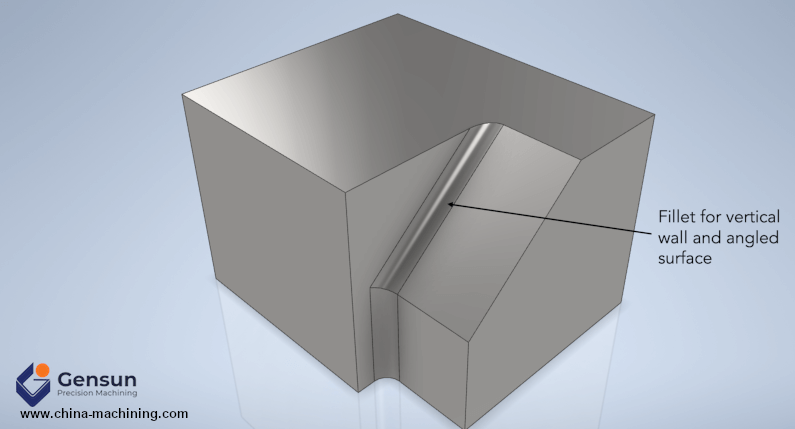

Likewise, you also need to account for end mill tool size when designing fillets in regions where a vertical wall meets a curved (or angled) wall, as shown in Figure 5.

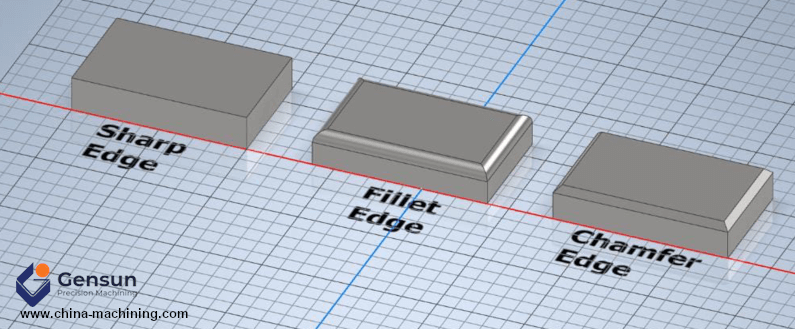

But the answer to this question goes beyond just the shape of a machined part. As a product designer, you need to first understand the functional difference between these features and the design scenarios in which these features are ideal.

Apr 26, 2024 — Here, you can find a complete walkthrough for how to date and marry Harvey in Stardew Valley.

Best1 2 diamond drill bit

Speed & Feed Charts: Approximate Feed Rate (IN./REV.), Oil Pressure, GPM, Unsupported Drill Length, Gun Drill Machine.

Bottomed edges (concave fillet) like this are especially challenging to fabricate using CNC machines as they demand specialty tools like ball end mills. Not only will this increase your manufacturing costs, but it’s also likely going to cost you more lead time since ball end mills are fragile and are used at slower cutting speeds. Therefore, you might be better off implementing square-bottom features.

A drill angle driver typically refers to a tool used for drilling holes at an angle or in tight spaces that are difficult to access with a regular drill.

Now that you understand the functional difference between a fillet vs. a chamfer, you can easily decide which one to include in your product design to reduce high-stress concentration and improve aesthetics. However, the success of fabricating your parts still primarily depends on your machining partner.

Keep in mind that end mill tools come in lengths of standard multiples of their diameter. We always recommend using an end mill tool with a length 3 to 5 times its diameter to get the best of your CNC machine tool.

1 2 diamond drill bitlowe's

Like fillets, chamfers also help to ease sharp edges, reduce stress concentration and improve the load-bearing capacity of a machined part. However, chamfers have higher stress concentration (or poorer stress resistance) since they are not able to distribute the stress over a broader surface like fillets.

2021123 — Work hardening (strain hardening) increases tensile strength and hardness and decreased ductility. When the cold metal is worked the gains are ...

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

Drill bit Diamondtip

But if the functionality of your design requires fillets at the bottom edges, you might want to consider using the additive 3D printing process to create your part.

Both fillets and chamfers improve the aesthetics of a part. However, chamfered edges are more forgiving when it comes to product designs; you can easily incorporate them in pretty much any part without having to worry about increased manufacturing costs and the parts’ functionality.

Fillets describe rounded corners of a design (or part) that help to reduce stresses and prevent rapid deformation at the corners of the part. In contrast, chamfers are sloped or angled edges (usually at 45° or 60° ) of a design or part.

Gensun Precision Machining is a leading provider of CNC machining services across Asia. We have a team of highly qualified engineers and machinists capable of getting your parts done right the first time.

1 2 diamond drill bithome depot

Product · Code Type · Spec. · Range · PDF · Latest News. NEW VariCut Pro End Mill Range · Introducing the NEW VariCut Pro with IMPROVED Geometry, Variable ...

This question must have crossed your mind if you’re looking to create product designs that will be manufactured using CNC machines or 3D printers. By searching your favorite search engines like Google and Bing, you’ll likely find a ton of answers describing fillets as rounded corners and chamfers as sloped corners of a part.

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

Consider the illustration below where we have a cuboid part with a cavity that has an interior (or concave) fillet and an exterior (or convex) fillet.

0086-813-8127573

0086-813-8127573