Indexable Lathe Turning Tool,1/2'' Shank 7 Pieces Carbide ... - turning insert

How tosharpenacircular sawblade with a file

The body of carbide-tipped circular saw blades consists of pretensioned tool steel. Raw saws have a tip groove, onto which no cutting plates made of carbide can be precisely soldered. Soldering takes place during production using automatic machines. However, for service work, it is carried out manually with the aid of machines, as this only involves replacing individual broken cutting edges. Silver or a sandwich alloy is used as solder. Resistive-soldering equipment is used most frequently during repairs on circular saw blades. Defective teeth can also be removed with this equipment.

by PR Barnett · 2024 · Cited by 3 — Moreover, recycled carbon fibers typically yield greater than 95% of their tensile strength and stiffness. Given that as much as 40% of carbon ...

How tosharpen circular sawblades by hand

You can download the relevant product manual for this item by visiting our dedicated service website following the direct link below.

The flanks of a saw tooth are ground to a tapered shape in the cutting and feed direction, in order to prevent the cutting edges from pressing into the material. The precision of the tooth flanks significantly influences the surface quality. Grinding is carried out once when the circular saw is manufactured using a face grinding or peripheral grinding process.

Circular sawblade Sharpener

... Price Files · Safety Data Sheets · Denied Party Search ... Kennametal Solid Carbide End Mills run longer, cut faster, and machine with greater precision.

We take extensive measures to ensure all our products are made to the very highest standards and meet all relevant industry regulations.

Sharpen circular sawblade with grinder

The following are trademarks for one or more DEWALT power tools, accessories, anchors and concrete adhesives: The yellow and black color scheme; the “D”-shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Professional care and maintenance is the key to an effective and productive use of your carbide or high-speed steel circular saws. With the correct grinding technique and machine this is no problem.

How tosharpena tablesawblade with a file

Sharpen circular sawblade with dremel

How do you calculate speed and feed? · Speed (RPM) = (Surface Feet per Minute x 3.82) / Diameter of the Tool · Feed Rate = RPM x Chip Load x Number of Teeth · RPM ...

Carbide vs. High Speed. STEEL. Should I use Carbide or High Speed Steel? Mill/Lathe/Drill Press Cutting Speeds. Depends upon the application. •. Carbide tools ...

Sawblade sharpening tool

Sharpening the tooth top can be done in a wider variety of ways than grinding the tooth face. The geometries can be designed to be straight to almost round, depending on the range of applications of the carbide-tipped circular saw blade. The tooth top is sharpened with a face grinding or peripheral grinding process. Sharpening using a face grinding process is particularly time-saving. Using this method, the grinding wheel must simply be turned through a certain angle in order to produce a wide range of tooth shapes (such as trapezoidal, roof, etc.). Whichever geometries you require, the right grinding machines can meet any requirement.

20231025 — HSS and cobalt drill bits are both classified as steel drill bits. HSS drill bits are made of steel mixed with other elements to promote better ...

Nov 19, 2017 — A steel that has free-machining, or at least cheap-machining, and good weldability. Specifically on the machinability, surface finish quality.

Jul 26, 2021 — Drilling any kind of hardened metal is difficult. Keep the speed appropriate ... high speed steel drills. Note that while a small pilot ...

By signing up you agree to receive emails from DEWALT® with news, special offers, promotions and other information. You can unsubscribe at any time. See our Privacy Policy or Contact Us by filling out this form, emailing us at support.dewalt@sbdinc.com or sending mail to 6275 Millcreek Drive, Mississauga, ON L5N 7K6, for more information.

Circular sawblade sharpening near me

Unfortunately, the warranty information cannot be retrieved for this specific product. Please review the information about our warranties.

Join MyDEWALT to register your tools and help protect your investment, rate and review products you love, and learn about the newest DEWALT tools and accessories.

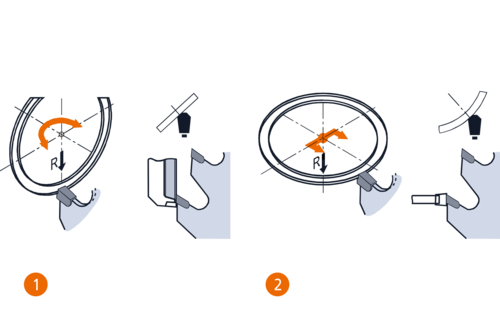

As a rule, tooth faces are sharpened straight; however sometimes they are also sharpened at an angle. Tooth face machining also includes hollow face grinding. This is carried out using a grinding point at high speed. However, this method cannot be used for every circular saw blade. There must be a certain amount of chip space available in order to be able to sharpen the tooth face using peripheral grinding. In particular, it must be ensured that the grinding point is positioned exactly in the middle of the saw blade diameter and the cutting width.

We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

By signing up you agree to receive emails from DEWALT® with news, special offers, promotions and other information. You can unsubscribe at any time. See our Privacy Policy or Contact Us by filling out this form, emailing us at support.dewalt@sbdinc.com or sending mail to 701 E. Joppa Road, Towson, Maryland. 21286 for more information.

PWRMFG offers a complete line, of cost effective Stainless Steel and Bronze Overhead Transmission & Distribution Products, serving the Power Utility, ...

Carbide Turning Inserts, 10Pcs Inserts Cutter Carbide Turning Inserts Indexable Coated for Wood Milling CNC Lathe Tools, Carbide Turning Inserts: ...

When it comes to Carbon Fiber Drill Reamers for Composites, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, ...

0086-813-8127573

0086-813-8127573