India's first travelling Podcast - The beginning and the END ... - etshow

Types ofconventional machine

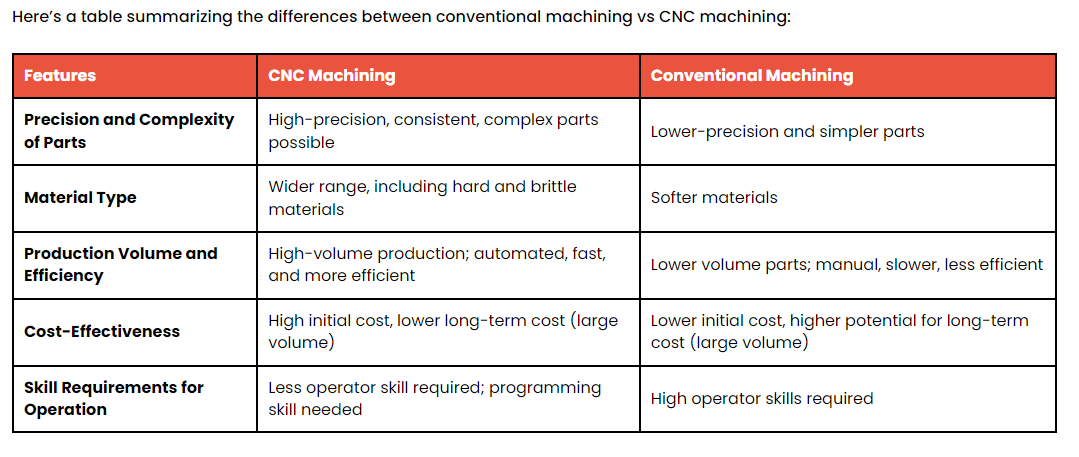

Skill Requirements for Operation: CNC machining requires less operator skill due to computerized control, ensuring consistent quality.

ECM machining

Locations and key contacts for Sid Harvey's 20.

Less Cost-effective for Very Small Batches: CNC machining may not be efficient for small-scale production due to high setup costs.

Ability to Produce Complex Shapes: CNC machines offer high manufacturing complexity capacity, excelling in creating intricate parts.

Difference between CNC andconventional machine

Precision and Repeatability: CNC machines replicate CAD drawings with near-perfect accuracy, ensuring precise results consistently.

Distinguish betweenconventionaland unconventional Manufacturing process used in Industries

Our Guy Harvey® Hammerhead Ring features just about every dreamy shade of blue you can imagine. The striking hammerhead swimming into the deep inspires us to do ...

Lower Initial Investment: Conventional machining tools are less expensive upfront, making them suitable for small workshops and startups.

Remember WEN? We've been providing reliable power tools since 1951. Shop woodworking, generators, lawn and garden, drill presses, lathes, and more.

Conventionalprocess meaning

Orders received by noon on the day before the beginning of the holiday should ship the same day.Normal operating hours resume on the first business day following the last day of the holiday.

Designers use Computer-Aided Design (CAD) software to create digital 3D models of desired parts, which are then translated into instructions (G-code) that CNC machines understand. These machines precisely remove material from a workpiece, guided by computer-controlled motors, resulting in high-quality parts with precise dimensions and intricate details.

Shop Iscar Metals Inc - Turning Inserts from Motion's wide selection. We offer the quality and service you need to keep your business in Motion!

by W Sun · 2014 · Cited by 16 — ... CFRP tensile strength can be developed before debonding occurs. In order to fully develop the tensile strength of CFRP strips, some form of anchorage is needed.

Machineoperation

Production Volume and Efficiency: CNC machines excel in high-volume production, offering automated and efficient processes.

Higher Potential for Human Error: Manual control introduces the potential for errors, increasing the risk of inconsistencies.

Dongrun Casting have 20000 square meters facility houses and 200 production & test equipment, From quotation and tooling design to casting and finished machining, we can work with you at every stage. We serves wide range of industries-from Fortune 500 corporations to small and midsize OEMs. Our products includes: Automotive&Trucking, Electric Utility & Communications, Metering System, Hydraulic Industry, Medical Devices, Lighting, Fuel and Gas Pressure, Furniture parts.

Precision and Complexity of Parts: CNC machining offers higher precision and complexity compared to conventional machining.

What is CNC Machining?CNC (Computer Numerical Control) machining is a subtractive manufacturing process that employs computerized controls and machine tools to shape raw materials into custom-designed parts. It integrates traditional machining with CNC technology, computer-aided design, and auxiliary manufacturing processes.

by J Bai · 2021 · Cited by 2 — The microstructure of high-carbon steel before tempering was martensite (over the saturated alpha phase) and retained austenite (or partly undissolved carbides) ...

In this guide, we delve into both CNC and conventional machining, exploring their mechanisms, strengths, and limitations. Our goal is to empower you with the knowledge needed to make informed decisions for your project. But before we delve into their differences, let's understand their basic principles.

RMP Products Ltd offers in-house plate Bevelling, Chamfering and Weld Preps with various forms of technology to ISO 9001 and CE Execution Class 4 standards.

Efficient for High-volume Production: CNC machining minimizes manual intervention, ensuring quicker and more consistent production.

Conclusion:The choice between CNC and conventional machining depends on specific needs and production objectives. While conventional machining may suit unique projects with lower upfront costs, CNC machining is preferred for high-volume production requiring precision and efficiency. Ultimately, understanding the capabilities of each method is essential for making the right choice for your project.

CNC machining

Conventionalmachining process pdf

CNC machining automates processes traditionally done manually, using computerized controls to shape materials with unparalleled precision. Conversely, conventional machining relies on manual guidance from skilled operators.

Order today, ships today. SEN-17731 – ATtiny85 Moisture Sensor Qwiic Platform Evaluation Expansion Board from SparkFun Electronics.

Mild steel can be hardened, somewhat, sometimes. Low carbon does not necessarily mean NO carbon. That said, you aren't going to make any ...

202013 — The corner radius refers to the radius of the circle that is created if the corner arc is extended to form a complete circle.

Cost-Effectiveness: While CNC machining has a higher initial cost, it offers long-term cost advantages for large-volume production.

In the manufacturing industry, various methods bring products to life, each suited to different projects. Understanding these techniques is crucial to determining the best fit for your applications. Today, we delve into two transformative machining techniques: CNC machining vs conventional machining. Each method has distinct advantages and drawbacks, influencing modern production.

Higher Initial Investment: CNC machines require significant upfront investment, making them less suitable for small-scale businesses.

Lower Precision and Repeatability: Conventional machining offers less precision and consistency compared to CNC machining.

What is Conventional Machining?Conventional machining involves shaping materials with manual tools and machines like mills, grinders, and lathes. Operators manually control these machines, adjusting cutting parameters based on experience.

0086-813-8127573

0086-813-8127573