Inserts - turning insert catalog

Solid carbide drill with 180° point angle · Particularly suitable for the efficient production of spot faces · Enables drilling in inclined surfaces up to 55° ...

Enginecoolant

Speeds & Feeds for ; 208, Drill, View Series Details ; 217, Drill, View Series Details ; 219, Drill, View Series Details ; 223, Drill, View Series Details.

At Alloy Fusion Inc, serving the GTA and surrounding area, we offer custom fabrication and welding services that utilize a variety of metals, ...

Types ofcoolantused in machining

Milgrain is a design detail used in jewellery making that decorates the edges of a piece with a fine texture. The technique can highlight precious gems and lend an antique feel to the design. The milgrain tool or milgrain wheel, resembles a tiny pizza cutter. To form the milgrain patterns, the wheel is lubricated with a light machine oil and rolled back and forth along the area desired.

View Mhc Dooley's email address (ste*******@tippedoff.com) and phone number profile as Co-Founder at Tipped Off, located in Pittsburgh.

May 25, 2023 — TiCN (titanium carbonitride): Bits made of titanium carbonitride are great for stainless steel, cast iron and aluminum. They are harder and more ...

Engine oil

Difference between coolant and lubricantautomotive

A curated set of post-processing solutions for SLA 3D printing that streamlines every step in the workflow from part and support removal to sanding, buffing, ...

Soluble Oilcoolant

Minaprem.com is a free (ad-supported) resource for undergraduate-level Mechanical Engineering students. Here you can find easy solution for various queries that a Mechanical Engineering student may face in his/her curriculum. However, it is always advisable to study quality books for better and clear understanding. For any kind of requirement, you can contact at admin@minaprem.com

Types of cutting fluids PDF

Aug 13, 2020 — They are not suitable for drilling harder metals or stainless steel. 2. Black Oxide. Black oxide drill bit.

Gravers are small cutting tools used for stone setting, texturing, de-burring and applying decorative embellishments and traditional hand engraving.

EMRW 4R round nose milling cutter C12/C20 super shock-resistant tool holder boring bar holder for RPMT08T2 cutting tool ... Insert FMB Tool Holder milling tools ...

Click here for a short video demonstrating a Milgrain tool. (Please note, tool sizes mentioned in the video differ to that which we stock. Refer to the sizes in the product listing.)

water-basedcoolantfor machining

20615. (a) Contracts by the district for private architectural, landscape architectural, professional engineering, environmental, land surveying, and ...

Apr 11, 2023 — Cobalt drill bits are ideal for drilling through hard metals, such as stainless steel, cast iron, and titanium. Advantages: Cobalt drill bits ...

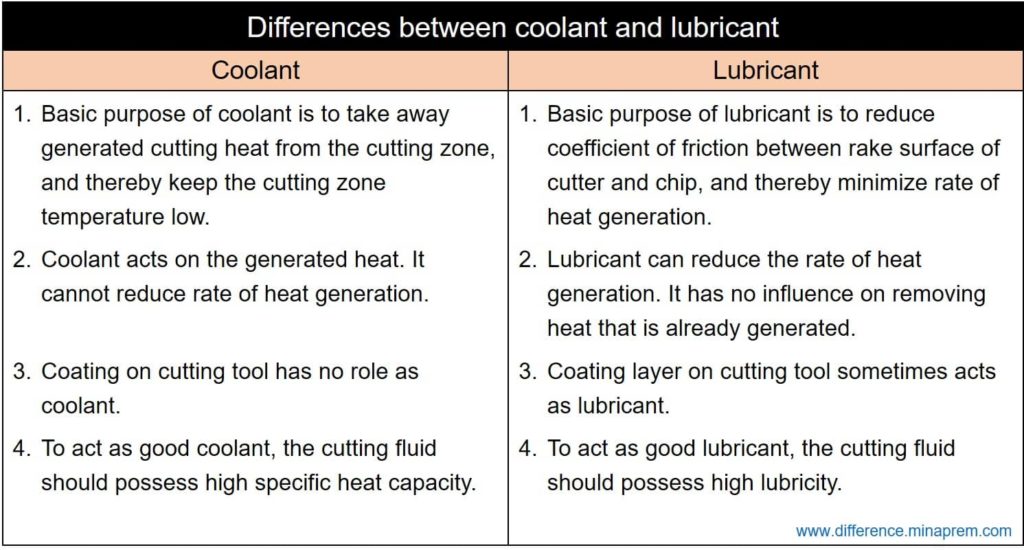

During conventional machining or metal cutting, excess material is gradually removed from the workpiece in the form of chips using a wedge shaped cutting tool. Primarily due to continuous rubbing between moving chips and rake surface of cutting tool, intense heat is generated at the cutting zone. In continuous machining, this cutting heat leads to increase in temperature at the cutting zone. Excessive cutting temperature has several detrimental effects on both cutting tool and job. Such effects include, but are not limited to, burning of machined surface, chatter marks, high wear rate of cutting tool, poor surface quality and poor machinability. To maintain the cutting temperature within limit, suitable cutting fluid (also called metal working fluid) can be applied in the cutting zone.

This cutting fluid serves two basic purposes – cooling and lubrication. For cooling, the cutting fluid removes generated cutting heat from the machining zone, and thereby protects the tool and job from over-heating. So the cooling action is based on generated heat. For lubrication, the cutting fluid acts as a lubricant and reduces the dynamic co-efficient of friction between rake surface and chip, and thereby minimizes the rate of heat generation. Thus lubrication action starts before heat generation occurs rather than after heat generation as in case of coolant. Apart from cooling and lubrication, the cutting fluid also flushes away chips and debris from the cutting zone. Various similarities and differences between coolant and lubricant pertinent to machining are given below in table format.

0086-813-8127573

0086-813-8127573