Internally Threaded Jewelry vs. Externally vs. Thredless - BM25 - internal vs external thread

One bit drills everything. Bad Dog Bits' unique Carbaloid tips resist fracture and stay sharper longer than conventional bits. SO DURABLE that they're ...

So, this is a ‘typical’ drill bit. Starting left, it has a Straight Shank which fits into the machine, and a body which is nicely decorated with flutes / cutting blades. At the far right it has a head which comes in a variety of designs, depending on its intended use.

100% original Korea Made Korloys turning inserts CNMG120404-HA PC9030 CNC lathe turning inserts cutting tools

In scenarios involving larger chamfer widths (such as C2 or higher), the radial cutting force intensifies, significantly amplifying chatter due to tool deflection.

Utilize an indexable chamfering tool equipped with a chip breaker to curb chip extension and entanglement with the tool.

Machining materials with burrs or sharp edges can swiftly damage tools. Chamfering in advance minimizes tool wear, prolonging tool life and ensuring more efficient machining processes.

Chamfer vs fillet

The chamfer width exhibits irregularity, attributed to tool deflection and chatter, varying based on the machined area and the hole’s phase. As a solution, the measures shown in the previous section”Chatter in Chamfering Processes” are also effective in this case.

Used to widen the opening of a hole, it cuts an angled groove into the wood so that when a ‘countersunk screw’ is inserted into the hole the head sits ‘inside’ the wood level, leaving a flush finish. The countersink bit cuts nice and smooth, but comes with a word of warning : do not push too hard, or it will cut a bigger hole than the head of the screw leaving only a messy and unprofessional looking finish.

Explore Tungaloy’s TungMeister line, featuring a diverse selection of exchangeable head tools designed for precise chamfering applications. These tools simplify tool replacement through their interchangeable heads. The TungMeister lineup includes three specialized head types—center drill, back chamfering, and R chamfering heads—ideal for both chamfering and spot drilling tasks, offering versatility to address specific machining needs.

EPSG:22420 NAD83(CSRS)v4 / UTM zone 20N - spatial reference system.

Naturally I understand that a variety of sizes makes sense … not every hole you want to drill will be the same size, however, this question never really had an answer until I started building projects which required the range of drill bits to present themselves.

The last in todays list is one that I’ve loved and hated. I’ve loved that it can cut accurate impressively sized holes, but I’ve also hated the fact that it can be painful to setup, and not all cuts are clean, plus it’s ability to jam-up is incredible.

How to pronounce chamfer

TUNGALOY CANADA 432 Elgin St. Unit 3, Brantford, Ontario N3S 7P7, Canada Phone: +1-519-758-5779 Fax: +1-519-758-5791 CONTACT FORM >

R-Chamfering involves a process dedicated to curving corners, notably effective in mitigating the risk of injuries. This method excels in ensuring smoother, safer edges.

Note : each drill is as important as the next, and the main reason for the variety of designs is quite simply that each one has a different job to do.

Chamfering serves more than just an aesthetic purpose; it yields numerous advantages, enhancing both product quality and functionality.

Sitrex / Fleming SM120/P,SM150/P and SM180/P Finishing Mower Replacement Blade Spindle.

The catalog features tens of thousands of parts with a seal profile index that will help you easily identify the seals you need. Profile sections include ...

Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. This slope is generally machined at a 45 degree angle, but the angle may vary depending on the use and purpose.

For nearly 40 years, our goal has been to make the Best Product at the Better Price - giving the customer maximum value. The 2023 PROFORM Catalog is 114 ...

Chamfer vs bevel

Tungaloy highly recommends DrillMeister, an exchangeable head tool featuring a chamfer body that significantly enhances chamfering efficiency.

Tungaloy´s main chamfering cutters, such as ECC and TungQuad, have a cutting edge design with a large rake angle that is optimized for chamfering.

feeds and speeds chart Keyseat Cutter feeds and speeds chart04032016_0001.jpg. Answers: cant leave messages here. Pages:(1) [1]. avatar. Eldar Gerfanov (Admin).

Chamfer Wood

By averting stress concentration—focusing stress in specific areas—chamfering improves the fatigue strength of components. Stress concentration refers to the accumulation of stress in particular zones, while fatigue strength measures a material’s resilience against repeated stress cycles.

The best way to now introduce the Drill Bit Family is by starting with its anatomy. Each drill bit has the same basic elements, but there are some today which are a little more advanced as to aid with faster wood removal, or adding a tread to the hole once the wood has been removed etc, very clever stuff.

Spade (Flat) : by far the cheapest drills available, and typically designed to cut larger holes, although the complete size range is available. Its centred spike keeps the drill steady whilst the main cutting blades remove the wood with ease, although the finish is not clean. This is a ‘rough and ready’ drill bit.

The consistent use of new heads prevents performance decline and quality fluctuations often induced by re-grinding and re-coating. This approach guarantees stable, prolonged tool life and consistently high-quality machining results.

Chamfered parts contribute to a uniform finish when painted or plated, resulting in a high-quality appearance that enhances the overall aesthetic appeal.

2017519 — Work hardening, also known as strain hardening or cold working, is the strengthening of a metal by plastic deformation.

Chamfered edge meaning

Chatter during chamfering arises from radial cutting resistance and tool deflection due to this resistance. Additionally, resonance vibrations leading to chatter may occur when the tool’s rotational speed aligns with its natural frequency. Employing tools with high rigidity minimizes deflection, elevates the tool’s natural frequency, and prevents synchronization between tool speed and natural frequency.

Employ a strategic approach of “step” or “dwell machining” during the machining process to forcibly break up chips. “Dwell machining” involves a temporary pause in feed progress while the drill spindle continues to rotate, aiding in chip fragmentation.

Opt for blades featuring substantial rake and helix angles alongside sharp cutting edges. This mitigates the radial cutting force, a primary contributor to chatter during chamfering.

Effective chip management is crucial to prevent the entanglement of chips that might otherwise lead to tool damage or workpiece impairment. Similarly to the occurrence of “Chatter in Chamfering Processes,” this issue often arises during continuous machining, especially when chamfering around holes.

Threaded : these drills are used not only to drill a hole into wood, but also to leave a thread in the wood. This thread can then be used by screws, but also by bolts. The threaded wood acts like a nut, securing the bolt in place.

Titanium (TiN) : coated with a super hard Titanium Nitride to keep the drill sharper for longer, it can be resharpened at a later date when blunt. This material also has a lower level of friction and so has a reduced heat temperature when drilling compared to other drill bits.

For example, if you look at the four corners of a smartphone, you will notice that the corners are diagonal, rounded, and chamfered to prevent pain.

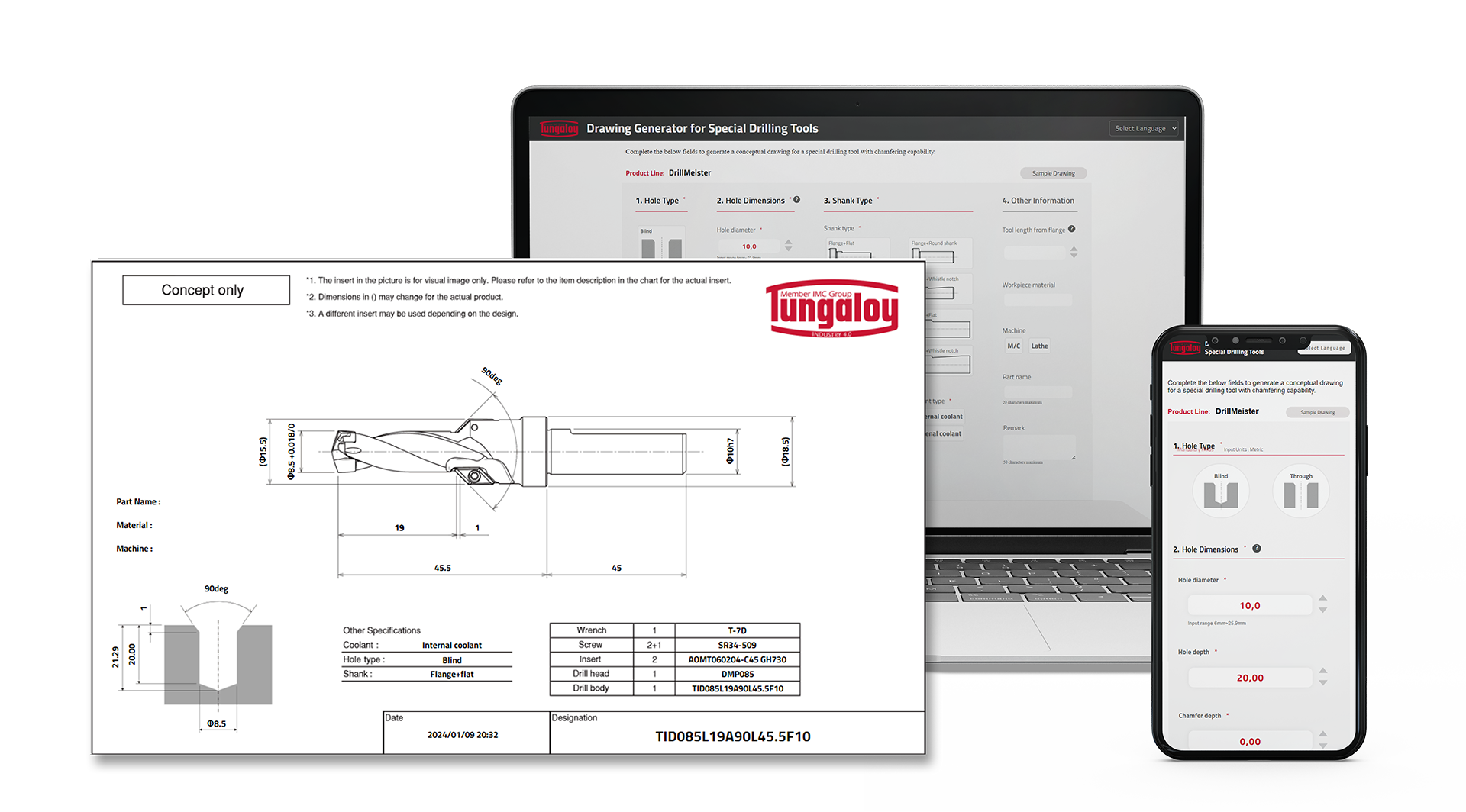

Introducing an innovative solution for creating drawings of specialized drilling tools, which was previously a time-consuming process.

Sometimes, reducing the number of inserts on the tool, such as transitioning from 4 to 2 inserts (or even down to 1 insert in specific cases) for indexable cutters, can help in damping chatter.

Chamfer in AutoCAD

Chamfering is often used in cooking because cutting off the corners of vegetables prevents them from collapsing during cooking and allows the flavors to soak in more easily.

This set shows 3 available sizes (from many) with the countersink attachment fixed in place. You can adjust or remove the countersink element (in this photo) by using an Allen Key or Hex Key, which is normally provided when you buy them. A downside to this design is that sometimes (from my experience) even after the countersink is fastened, it will work itself loose due to the vibrations of the drill working. But not always.

A Gimlet is typically referred to as ‘the screw starter’. Rotated clockwise and orientated by hand, it is possibly the first ever drill … just without the machine. As the user pushes and rotates the Gimlet, it penetrates the outer layer of the wood. This makes a small hole enabling the screw to sit inside the wood, allowing the thread to bite and not just rub / scratch over the surface. This little gem is a must have for any woodworker.

Chamfered edge

Thread chamfering is a meticulous process that delicately trims corners to an imperceptible degree. It serves a unique purpose, ideal in cases where neither C-Chamfering nor R-Chamfering is required. Instead, the focus remains on eliminating burrs to an extent that escapes visual detection.

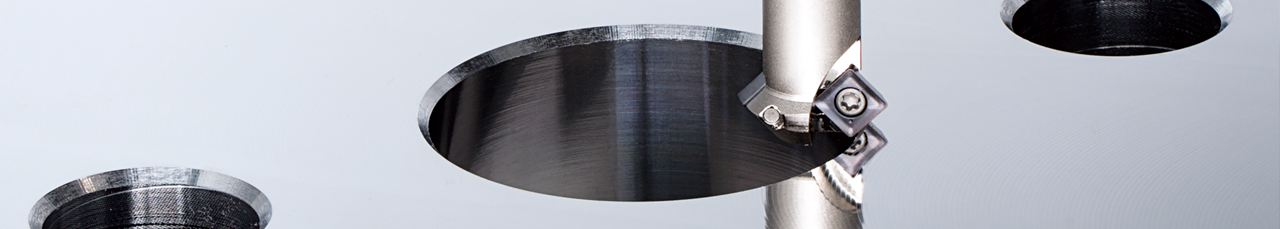

DrillMeister’s specialized exchangeable head drills revolutionize machining by merging innovative design with practicality, resulting in heightened machining accuracy, efficiency, and cost-effectiveness.

The advanced powder coating system employed by Harvey Vogel saves time and money by allowing us to complete all parts of the manufacturing process in-house.

DrillMeister’s special chamfer employs inserts with chip breakers that effectively manage chips during chamfering, preventing elongation and entanglement, thus improving chip control.

It would be a shame to end this blog here without mentioning some of the friends of the Drill Bit family … one very close friend is the Countersink Bit.

Reducing rotation speed often resolves chatter, though this approach can impact machining efficiency and surface quality. Balancing these trade-offs and optimizing rotation speed effectively minimizes vibration.

During chamfering, encountering chatter represents a notable issue. This phenomenon, known as chattering, becomes particularly problematic when chamfering around holes using a punching technique. A common occurrence is observed when executing a C chamfer with a 45-degree angle, resulting in a tool edge aligned at the same angle. This alignment escalates the cutting force, directing deflection towards the tool diameter.

Explore the “Drawing System for Special Drilling Tools”! By inputting essential tool details, you can swiftly generate straightforward diagrams illustrating special drilling tools with chamfering functions.

3 Flute Carbide Chamfer Cutter Solid Carbide Chamfering for Aluminum Without Coating, Find Details about Cutting Tool, Carbide Core Drill from 3 Flute ...

Chamfer Tool

C-Chamfering represents a prevalent technique where edges are sliced at a precise 45° angle. Often, discussions surrounding “chamfering” primarily allude to this method. Practical directives such as “C1” are commonly employed in on-site procedures, indicating the removal of a 1mm width from the edge.

Decreasing chamfer width proves effective in curbing tool deflection and subsequently suppressing chatter. For instance, when handling larger chamfers (C5 or higher), pre-machining the workpiece into a multi-stage hole shape using a drill or counterbore cutter helps reduce machining allowances and dampens vibrations during chamfering.

Forstner : almost always used in a drill press / pillar drill, they are called a ‘flat-bottomed’ drill bit, except for a small point which keeps it centred, and can be used for overlapping holes.

The tool’s overhang length and the drill’s distance from the chamfering edge remain constant with an exchangeable head drill. This maintains dimensional accuracy during machining, significantly reducing the risk of defective workpieces.

Hole Saw : great for cutting bigger sized holes than that of standard drills. It fits into almost every machine, both on a table or in hand. Sadly the teeth do tend to bind up, and as well as getting very hot, it must also be used at slower speeds as to allow the teeth to cut and not just spin around. This photo shows a fixed Hole Saw, but there are also models available which allow you to adjust blades to make viable sized holes.

0086-813-8127573

0086-813-8127573