ISO Inserts - Designations, Dimensions & Tolerances - turning insert designation system

I won't climb-cut with a router bit that is too large to safely control. For larger bits that aren't too large, or anytime I don't feel completely in control, then I will plant my fist in one spot and make short, shallow strokes by rotating the router into the cut with the other hand.

Northern Toolsale

Conclusion Don't perform any operation just because someone else has done it without problems. Regardless what you do, or how you do it, routers and shapers are dangerous tools. You must operate them with 100% confidence, but never let your respect for them drop either. Operate the tool with respect. Never, never, operate a tool when you have a "fear" of the tool, or operation. There is a thin line between respect, and fear. Don't cross that line, or you will be injured.

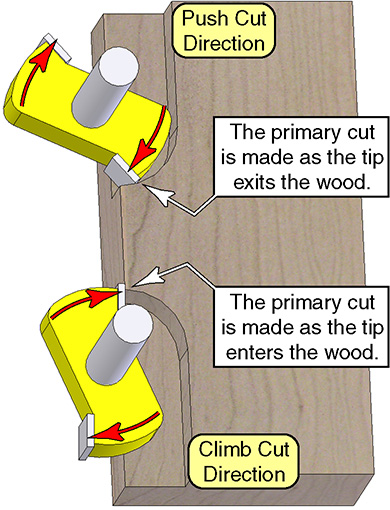

Push-Cutting Push-cutting refers to the feed direction of your workpiece which opposes the rotation of the cutter head. Push-cutting is typically considered the "normal" feed direction because it is safest: the router doesn't want to runaway on you. However, push-cutting has the greater tendency for tearout. As the carbide tip strikes the wood, the path of the cutter travel is out of the wood, and the deepest cut is in-line with the grain. The result, is that the carbide is cutting the wood on the Exit Stroke.

With friction, there is no reaction time needed, there is just a constant force opposing the climb. While holding the router's handle, the butt of my fist is pressed down firmly onto the surface of the wood. When starting or stopping a cut, I firmly plant my fist on the wood, and use the other hand to rotate into or out of the cut. This gives me very good speed control over a short distance. As I move down a long board, I just drag the edge of my fist (or even forearm) down the wood.

Students at a Texas high school will get the chance to build a monster truck thanks to a new partnership between Northern Tool + Equipment and Monster Jam.

Partnerships The company has partnered with Monster Jam, Vcsedu, and NASCAR Hall, indicating a focus on collaboration and co-branding opportunities. Leveraging these partnerships can open doors to joint marketing initiatives and cross-promotional sales efforts.

Harbor Freight

Product Launches Northern Tool has recently launched new product lines such as Klutch Cordless Power Tools and NorthStar Engines. These innovative offerings provide a fresh angle for sales representatives to promote and potentially upsell to existing customers.

Northern Toolstore inventory

Furthermore, I use friction to control the feed rate, not muscle. When you try to muscle the router to control the feed rate, then you are relying on your reaction time to compensate for changes in the feed rate. You can never react fast enough.

Product Diversity With a wide range of products catering to both consumer and industrial needs, Northern Tool offers a diverse portfolio for sales representatives to explore. This breadth of offerings allows for cross-selling and meeting various customer demands effectively.

Most of the time, I do not need a cleanup pass on the shaper, but the smaller the feeder, the more important this will be. If a cleanup pass is needed, you can either change the feed direction to chip-cut, or leave it in the climb-cut. I usually stay in the climb-cut direction.

Northern Toollocations

Retail Expansion Northern Tool has been actively opening new retail locations across the United States, including Ohio and Bossier City. With each new store, there is an opportunity for local sales teams to engage with customers in those regions and drive revenue growth.

Global Expansion Northern Tool + Equipment opened a location in Hyderabad, India in 2021, expanding their reach internationally. This presents an opportunity to explore sales strategies in a new market and tap into a different customer base.

Climb-Cutting Climb-Cutting is when the feed direction of the workpiece is the same as the rotation of the cutter. The term climb-cut comes from the fact that the router bit has the tendency to climb into the cut, or if you can visualize it, "walk" its way down a board. This is what makes climb-cutting so dangerous: the router bit has more control over the feed rate than you do, and if you don't carefully control it, the router or workpiece will take off on you.

NorthernTools catalog online

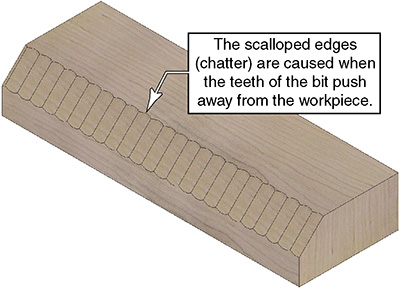

Cleanup Pass After the first pass, I make a cleanup pass in the chip-cut direction. This ensures that the route went full depth, and also removes the chatter marks left by the climb-cut. Because the majority of the material has already been removed, the direction that the carbide tips strike the wood is nearly parallel to the grain, and therefore, no chipping occurs. I also make this last pass with a fairly fast feed rate to ensure that there is no burning.

Northern Tool + Equipment uses 8 technology products and services including Northstar, Power BI, Kronos, and more. Explore Northern Tool + Equipment's tech stack below.

Tractor Supply

BURNSVILLE, Minn., Jan. 16, 2024 /PRNewswire/ - Northern Tool + Equipment has launched a new line of NorthStar Engines with multiple options ranging from 180cc to 825cc.

So you've built this beautiful jewelry box. Now comes the moment to add the finishing touches, like routing a nice decorative profile around the top. ----Craaaack!----There goes a 3 inch long chip from the edge, destroying many hours of work.

NASCAR Hall of Fame driver Richard Petty and motorcycle builder Billy Lane have teamed up with Northern Tool to launch the "Tools for the Trades" program.

Northern Toolpromo code

Aside from wanting to climb its way down the board, another side effect of climb-cutting is that the bit will be pushed away from the wood. As the carbide enters the wood, the force of the tip striking the wood surface tends to push the wood away from the bit. This has two effects. First off, the cut will almost never be full depth on the first pass of the cut. Secondly, since the cutter tips keep pushing the bit away from the wood twice per bit revolution, you end up with more chatter. This chatter is caused from the cutter bouncing in and out as each knife strikes the wood.

Applying These Concepts The First Pass To reduce the tearout while routing, I make the first pass in the climb-cut direction. To prevent the router from running away on me, I make this pass rather light. Since the router bit is naturally pushed away from the wood during climb-cutting, making a light pass is automatic: I just don't apply as much inward force.

BURNSVILLE, Minn., May 21, 2024 /PRNewswire/ - Northern Tool + Equipment has launched a line of Klutch Cordless Power Tools designed to offer reliable technology, durability and convenience.

You can prevent tearout when using a router; its just a matter of the feed direction. There are two choices when it comes to the feed direction with a router: Climb-Cutting, and Push-Cutting.

Northern Tool + Equipment is truly a multi-channel retailer offering a wide selection of products â from consumer goods to industrial and construction equipment â to do-it-yourselfers, contractors and professional shops via catalog, internet (northerntool.com), mobile and retail locations. Our headquarters are in Burnsville, MN, and we have warehouses in Savage, MN, Fort Mill, SC and Arlington, TX. We manufacture North Star, Powerhorse, and several other brands at our facilities in Faribault, MN and Ningbo, China. With over 120 store locations across more than 20 states, Northern Tool has a strong retail presence in the U.S. But the Northern Tool experience doesn't stop there. Add in our year-round catalog offerings, a website packed with over 100,000 tools, curbside store pickup, nationwide delivery and a team standing by on the phone always ready to take your order â and the possibilities are endless. But despite the many ways to shop, we're still always here to treat you with that familiar, trustworthy customer experience plus the endless knowledge and support of an entire team of product experts online, on the phone, on the floor and in the field. In 2021 we opened our Hyderabad, India location. The hub in Hyderabad, India provides significant support to our business with a wide-range of capabilities. NTE India is an extension of our headquarters and expands Northernâs reach to find talent which supports our strategic growth plans. As we grow, we recognize having a global talent strategy is critical to the success of our business. The team in India is accelerating innovation to provide our customers with compelling new products and solutions. Our top-notch team bases every decision on six fundamental core values â Know Your Customer; Provide Value; Act With Integrity; Empower The Individual; Be Entrepreneurial; Have Fun. Diligently practicing these values has resulted in recognition as a "Minnesota Top Workplaces" recipient for 5 consecutive years.

The drawback to this direction, is that it tends to tearout the wood more, because the wood fibers will easily split lengthwise. As the cutter catches each fiber, it tends to pull it away from the main body of wood.

Using a Router in a Table When hand feeding stock through the shaper or table mounted router, don't even consider climb-cutting: It's a good way to lose a finger. You have no way to control the feed rate when you are moving the workpiece on a table. While you may think you can stop the piece from grabbing and taking off, you can't.

Northern Toolnear me

Putting aside the dangers, the primary benefit to climb-cutting is that there is less, or even zero tearout. This is because the carbide strikes the wood with the deepest portion of the cut cross-grained and into the wood. That is to say, the carbide is cutting the wood on the Entry Stroke, which is compressing the wood fibers versus pulling them apart.

At the same time as the wood fibers are being pulled away from each other, the cutter head is being pulled deeper into the main body of wood. If the cutter has a bearing, this direction of cut will have the tendency to force the router to ride into the bearing (or fence) more.

If you have a power feeder for the shaper/router table, then climb-cutting is feasible, but still very dangerous. My shaper is setup to do 95% climb-cutting, but I have a rather large power feeder (shown in the adjacent photo). The small "baby" power feeders, may not provide enough workpiece control for climb-cutting. Regardless of your feeder size, this is still dangerous. Never allow anyone to stand in the outfeed path.

"Volusia County Schools is excited for our CTE programs to partner with Northern Tool + Equipment and Sons of Speed to provide this unique opportunity through the Tools for the Trades program.

0086-813-8127573

0086-813-8127573