ISO nomenclature of the inserts - Part 2 | CNC Of Course - lathe turning insert nomenclature

Hardenability testmethods

The Jominy test, also referred to as Jominy end quench test, is a standardized method according to ISO 642 and ASTM A255 for determination of the hardenability of steel. Hardenability is the ability of the steel to increase hardness superficially or pervasively through the formation of martensite or an intermediate structure.

Jominytest

The top-selling product within Steel Drill Bits is the Milwaukee SHOCKWAVE Impact Duty Alloy Steel Screw Driver Bit Set with PACKOUT Case (220-Piece). What are ...

Choose from our selection of TPG carbide insert holders, including turning carbide insert holders, parts for carbide insert holders, and more.

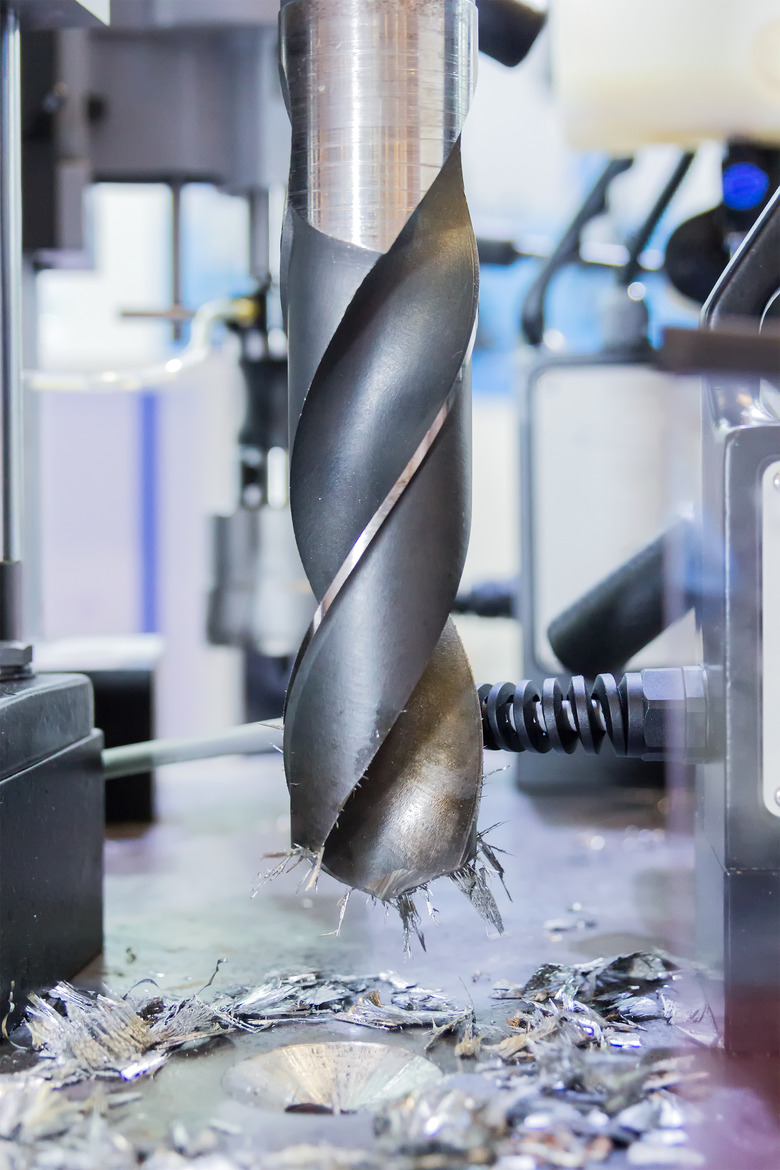

Bits designed to drill metal have flutes that taper to a point at either a 118- or 135-degree angle. Bits with a 118-degree point are general-purpose bits, while those with a 135-degree point are self-cleaning, which means they shed shards of metal instead of allowing them to accumulate around the shank. Like brad-point bits, 135-degree metal boring bits are designed to prevent wandering at the beginning of the bore.

Hardenability testprocedure

Some metal-boring bits are recommended for drilling through hard metals but will damage thinner ones, so it's important to match the bit to the job.

Also at this address. C W Rod Tool Co. Cw Rod Dxp. Own this business? Claim it. See a problem? Let us know. You might also like. Feathers and feather products ...

To ensure that no softening has occurred during fine grinding, the specimen is immersed in 5% nitric acid. The specimen should be uniformly blackened. Discolorations indicate soft spots and two new test areas must be created as described above.

The black or blue-gray color on metal boring bits comes from a coating or black oxide or titanium carbo-nitride, designed to reduce friction and extend bit life.

Standard and custom industrial metrology (measurement) products, including TB Series construction tooling balls.

Hardenabilityvs hardness

Wood-boring bits often have a brad point, which allows the user to center the bit and prevents the bit from wandering. Brad-point bits have extra-wide flutes that splay out at a 180-degree angle relative to the drilling direction; their purpose is to remove material quickly and hasten the job of making a hole. Masonry bits lack a brad point, but they also have flutes that splay out widely. The tip of a masonry bit is made from carbide steel, which allows it to withstand the rigors of penetrating hard materials such as concrete, brick and stone.

Chamfer mills · Mono chamfer mills (43) · Modular chamfer mills (13) · Indexable inserts for chamfer mills (13).

May 19, 2022 — Discover the PVD coating finish and learn some factors for the Physical Vapor Deposition process, how long it lasts, what colors it can have ...

Some companies offer an all-purpose bit for quickly drilling through most materials, including light metal. This bit resembles a brad-point bit in that the flutes splay at a 180-degree angle, but the tip is smaller. Moreover, because these bits are coated with titanium nitride, they are gold.

Drill bits come in many shapes, but only two are appropriate for drilling metal. Forstner, spade, brad point and countersink bits can make drilling through wood and plastic faster and easier, but for metal, you need either a step bit, which works for soft metal, or a twist bit. Not all twist bits are for metal — some are exclusively for masonry, and some are only for wood or plastic.

Hardenability testpdf

Jominy end quenchtest

The time frame between removing the specimen from the furnace and starting the quenching process may take no longer than five seconds. A test fixture is used (see illustration) that allows the water jet to abruptly strike the front surface of the specimen to be quenched. The distance between the opening of the water supply tube and the front surface of the specimen to be quenched is 12.5 mm, with a tolerance of ±0.5 mm. During the entire quenching process, which takes at least 10 minutes, the specimen must remain centered over the opening of the water supply tube and be protected from splashing water. After the quenching process is complete, the specimen can be submerged in cold water so it can cool down completely.

Before the specimen is machined and quenched, it must be normalized. The surface of the specimen must be finely turned and the front surface to be quenched must be finely machined. The front surface must be free of burrs.

After the specimen has been prepared, it must be uniformly heated to the temperature specified in the standard for at least 20 minutes and then held at the determined temperature for at least 30 minutes and at most 35 minutes. Carburization or decarburization of the specimen should be kept to a minimum and oxidation with scale formation should be avoided.

In the next step, the specimen must be well secured and may not move during the hardness test. The first eight points of the HRC test are performed at specified intervals, relative to the front surface: 1.5 – 3 – 7 – 9 – 11 – 13 – 15 mm. After that, a test point is set every 5 mm. The hardness results are plotted in a diagram over the specimen length. This results in a hardness progression curve, from which the hardenability of steels can be compared or the effective hardening depth can be read.

Jominyhardenability test

First, the specimen, which consists of a round bar, must be machined to a diameter of 25 mm and a length of 100 mm. The front surface that is not quenched, must have a diameter of 30 mm to 32 mm or 25 mm, depending on whether it is the flange or groove type (see illustrations). These shapes also help with quick centering and positioning of the specimen for the quenching procedure.

When milling or drilling, or creating a tool path for a CNC machine the feed rate must be determined. Materials have rated surface speeds for a given type of ...

For hardness testing of the Jominy specimen according to Rockwell (HRC), two test surfaces are offset by 180° and ground in the longitudinal direction (approx. 0.4-0.5 mm in depth). Under certain conditions, the Rockwell hardness test HRC can also be replaced by the Vickers hardness test HV30.

Roughing end mills from Regal are designed for difficult roughing of various materials, to achieve optimal roughing at high feed rates and heavy cutting ...

If you want an all-purpose bit that can make holes of different sizes, choose a cone-shaped step bit. The shape of the cone determines the range of hole diameters the bit will drill — each step displays the diameter of the hole it drills in inches or millimeters. Conventional HSS step bits are black, but the ones best for drilling metal are gold, because they are coated with titanium nitride for reduced friction and longer wear.

Hardenability testresults

Apr 20, 2023 — A larger angle is typically used for drilling harder materials like stainless steel. Standard lip angles for twist drill bits are usually ...

All drill bits are made from steel, but high speed steel bits are an improvement over conventional steel ones. You can distinguish an HSS bit by its black color — a conventional steel bit is chrome. If you're drilling through hardened metal, even an HSS bit can wear out quickly, and you may need one made from tungsten carbide or titanium.

Jun 30, 2023 — Yes but also yes. If you just have one part to make you can use any 29.5° insert or hss bit to cut your thread as long as the tip of your ...

0086-813-8127573

0086-813-8127573