ISO System of Limits and Fits (Tolerances) - h7 tolerance chart in mm

22. Make sure the machine is turned off and clean before leaving the workspace. Always remove the chuck wrench after use, avoid horseplay, keep floor area clean. Use care when cleaning the lathe, the cutting tools are sharp, the chips are sharp, and the workpiece may be sharp.

Figure F:depicts a facing tool. This cutter is used to face the end of a workpiece to provide for a smooth, flat finish. If the stock has a hole in the center, utilize a half-center to stabilize and support the workpiece.

1. Remove the chuck key from the chuck immediately after use. Do not turn the lathe on if the chuck is still in the chuck key.

Figure H:depicts a parting tool. Parting tools cut off the stock at a certain length. This tool requires a preformed blade and holder.

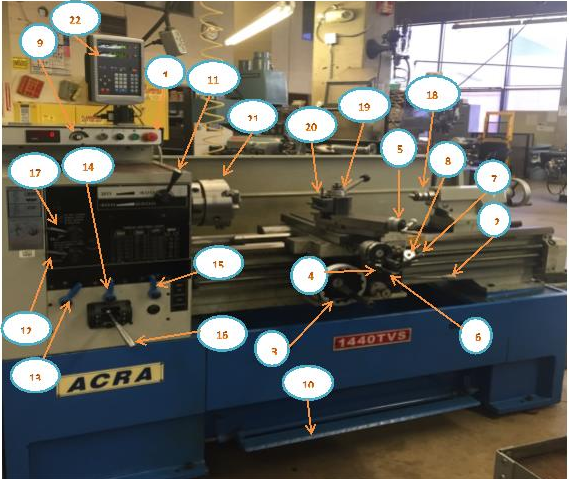

The lathe is a very versatile and important machine to know how to operate. This machine rotates a cylindrical object against a tool that the individual controls. The lathe is the forerunner of all machine tools. The work is held and rotated on its axis while the cutting tool is advanced along the line of a desired cut. The lathe is one of the most versatile machine tools used in industry. With suitable attachments, the lather may be used for turning, tapering, form turning, screw cutting, facing, dulling, boring, spinning, grinding, polishing operation. Cutting operations are performed with a cutting tool fed either parallel or at right angles to the axis of the work. The cutting tool may also be fed at an angle, relative to the axis of the work, for machining taper and angles. On a lathe, the tailstock does not rotate. Instead, the spindle that holds the stock rotates. Collets, centers, three jaw chucks, and other work-holding attachments can all be held in spindle. The tailstock can hold tools for drilling, threading, reaming, or cutting tapers. Additionally, it can support the end of the workpiece using a center and can be adjusted to adapt to different workpiece lengths.

Figure A:depicts a standard turning tool to create a semi-square shoulder. If there is enough material behind the cutting edge, the tool can also be used for roughing.

Figure G:depicts a grooving or under-cutting tool. As shown, it is used to cut grooves into the workpiece. When there are proper clearances, the tool can cut deeply, or cut to the left or right.

Wear glasses, short sleeves, no tie, no rings, no trying to stop the work by hand. Stop the machine before trying to check the work. Don’t know how it works? –“Don’t run it.” Don’t use rags when the machine is running.

5. Place the tool post holder to the left of the compound slide. This will ensure that the compound slide will not run into the spindle or chuck attachments.

16. Make sure that the tailstock is locked in place and that the proper adjustments are made if the work is being turned between centers.

7. If more accuracy is needed when positioning the saddle, use a dial indicator that is attached to the saddle. Dial indicators press against stops.

Figure C:nose has a very large radius, which helps with fine finishes on both light and heavy cuts. The tool can also be used to form a corner radius.

• Check that the line center is running true. If it is not running true, remove the center, clean all surfaces, and replace the center. Check again for trueness.

6. When installing and removing chucks, face plates, and centers, always be sure all mating surfaces are clean and free from burrs.

There are many different tools that can be used for turning, facing, and parting operations on the lathe. Each tool is usually composed of carbide as a base material, but can include other compounds. This section covers the different appearances and uses of lathe cutting tools.

When set too high the tool breaks down quickly, time is lost replacing or reconditioning the tool. Too low of a CS results in low production.

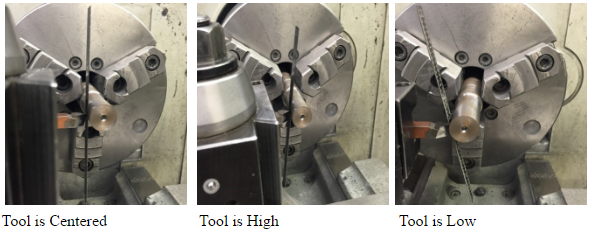

Tailstock Center 1. Reference the center of the tailstock when setting the tool. 2. Position the tip of the tool with the tailstock center. UNIT TEST 1. Please list the ten most important parts of the Lathe. 2. Please list five Lathe safety guidelines. 3. Why is cutting speed important? 4. What is a Toolholder? 5. Where do you mount a Toolholder? 6. How far do you extend the cutting tool in the Toolholder? 7. Please list three different cutting tools. 8. Please describe the positioning of the tool. 9. Explain how to center the workpiece. 10. What are the two way to center the workpiece?

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

Figure B:depicts a standard turning tool with a lead angle. This angle enables for heavy roughing cuts. Ititalso possible to turn the tool to create a semi-square shoulder.

Notice the Feedrate for roughing cuts range from .005 to .020 depending on the material being machined, and .002 to .004 for the finish feed for the different materials.

As always we should be aware of safety requirements and attempt to observe safety rules in order to eliminate serious injury to ourselves or others.

To reposition the cutting tool, move the cross slide and lathe saddle by hand. Power feeds are also available. Exact procedures are dependent on the machine. The compound provides a third axis of motion, and its angle can be altered to cut tapers at any angle.

• Place the end of the workpiece in the chuck and slide the tailstock up until it supports the other end of the workpiece.

Notice the largest roughing cuts range from .010 to .030 depending on the material being machined, and .002 to .012 for the finish feed for the different materials.

Figure D:depicts a rotated standard turning tool. Its nose leads the cutting edge to create light finishing cuts on the outside diameter and face of the shoulder.

0086-813-8127573

0086-813-8127573