Jobber Vs Mechanics Length Drill Bits - bit jobber

HSS tubes are often welded to through plates or shear end plates to help reinforce structural supports, but two specific rules of welding apply:

Since A500 Grade B is one standard in HSS tubing, let’s take a closer look at the chemical composition, mechanical properties, tolerances, maximum twist, and other important details.

HSS steelsizes chart

HSS tubes are commonly used in building construction for various structural components such as columns, beams, and pillars. They provide strength and stability to the structures while also allowing for design flexibility.

HSS is characterized by its high strength-to-weight ratio. The grades used to produce HSS tubing can vary depending on the application, but in general, they are of grades that are durable, formable, and weldable.

HSS tubes conforming to ASTM A500 B standards are made through a process of cold-forming and welding, utilizing carbon steel to provide essential structural support for various load-bearing applications such as buildings and bridges. A500 Grade B is the most common specification for square, rectangular, and round HSS, and 98% of the time it will also meet the specifications for A500 Grade C.

When handling HSS steel, welders typically use one of three types of welds: complete‐joint‐penetration (CJP) groove welds, partial‐joint‐penetration (PJP) groove welds, and fillet welds.

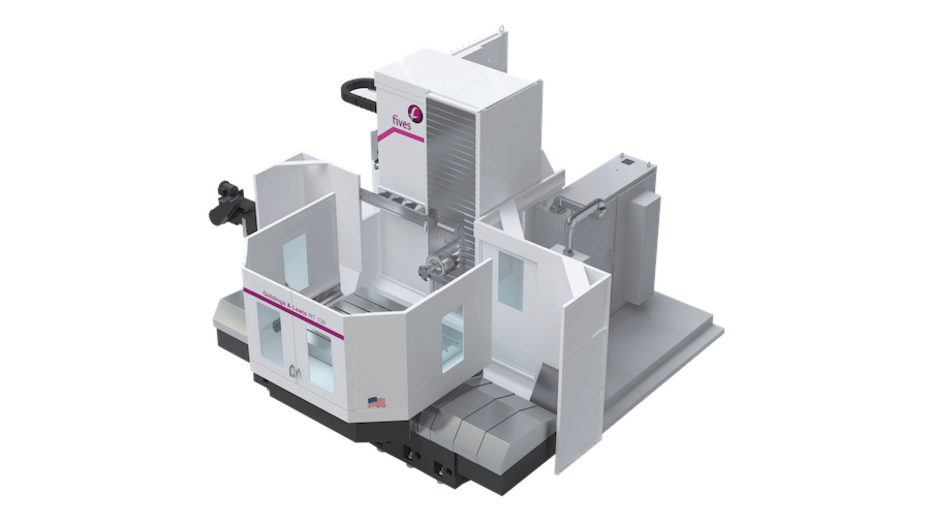

The machines offer the signature high stiffness, accuracy and reliability of the Giddings & Lewis brand, at a price point that is appealing to a wide range of industries.

Square HSS and jumbo tubes are typically available in A513 mechanical tube and A500 structural tube. Square jumbo tubing is suitable for applications requiring uniform geometries across multiple cross-sections.

HSS tubing refers to a type of steel tubing constructed with a hollow, circular, square, or rectangular cross-section. It is commonly used in construction, engineering, or architectural applications for columns, beams, trusses, or other structural elements. HSS tubing is valued for its strength, durability, and versatility, as well as its aesthetic appeal in certain design contexts.

HSS tubes made to ASTM A513 standards are available in various sizes, thicknesses, and shapes and can be produced with different finishes, including bare steel, galvanized steel, or painted.

HSS tubes are used in industrial machinery for their ability to withstand high loads and pressures. They are often used in the construction of hydraulic cylinders and brackets, spacers, pump bases, machine frames, machine bases, and other structural components.

In general, HSS tubes are available in metric sizes as well as imperial sizes. Metric sizes range from 10mm to 600mm with wall thicknesses up to 40mm. The imperial sizes include fractional sizes (1/2” – 4”) and schedule sizes (5” – 24”). But, as a North American metals supplier, our focus here will be on imperial sizes.

Designed with a modular set-up, the Giddings & Lewis FTR 3500/5000 models can be fully customized to meet the needs of your individual application.

Structurally, there is no difference between HSS and tube steel (TS). At one point, all tubular steel was simply called tube steel or TS. The American Institute of Steel Construction (AISC) began using HSS in the early 1990s to transition from using TS to using HSS.

What is hss steelused for

Equipped with a standard boring mill live spindle, the Giddings & Lewis FT features programmable boring bars and contouring heads to add machining versatility and reduce the number of tools needed. Automated attachment-changing optimizes efficiency and reduces cycle times. Even large attachments can be automatically changed.

HSS tubes can be coated or painted to resist corrosion, ensuring that they have a long service life and require minimal maintenance.

With a built-in contouring rotary table and an additional axis, these machines are ideal for boring prismatic parts that require work on multiple surfaces. Meanwhile, the one-piece rigid machining platform, which is characteristic of all Giddings & Lewis boring mills, makes easy work of heavy, high-precision cuts.

This change was intended to create consistency across the global marketplace. In Canada, Asia, and Europe, manufacturers use other terms, including CHS (circular hollow section), SHS (square hollow section), and RHS (rectangular hollow section).

The Giddings & Lewis RT Series of boring mills are designed for exceptional versatility, making them a smart choice for a wide range of industries, including aerospace, automotive, mining and defense.

HSS tubes are also used in architectural applications for their aesthetic appeal. They can be used in the construction of decorative fencing, gates, or other ornamental structures.

The Giddings & Lewis PT 1500/1800 boring mills feature preloaded roller guide ways, which offer significant advantages over other types of way system.

Giddings & Lewis are renowned for producing the most rigid and accurate machining platforms in the industry. The PT Series machines have a stiff machining platform, comprising a one-piece column base and bed. In addition to high precision, high stiffness gives thesemachine tables a substantial weight capacity, with the ability to handle parts weighing as much as 40,000 kg.

It is important to note that the exact size of an HSS tube may vary due to manufacturing tolerances. That is why it is essential to check the actual measurements with your steel service center before buying HSS steel.

Kloeckner Metals is a full-line hss tubing supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions.Contact Us Now

HSS steelgrades

Designed with a single-piece cast iron bed, Giddings & Lewis boring mills provide exceptional rigidity and unrivaled accuracy. The inherent high stiffness in the machines guarantees a reliable performance over and over again, with minimal downtime.

HSS tubing–standing for hollow structural sections–provides economical, high-strength support for construction projects and mechanical applications. Responsible for approximately 18% of the structural steel market, HSS tubing is known for its multidirectional load bearing and comes in a variety of different shapes, including round, square, and rectangular. Stocking HSS tubing throughout our footprint of 40+ North American branches, Kloeckner Metals is proud to supply a complete guide to HSS tubing to our current and future customers.

High precision doesn’t need to mean reduced efficiency. With a fast traverse rate of 25 m/min, as well as fully automatic tool-changing capabilities and a dual pallet shuttle, the Giddings & Lewis MC 1250/1600 models achieve exceptionally high productivity rates.

High speedsteelcomposition

Enclosed structural sections offer an advantage in their ability to withstand torsional loads. Furthermore, in industries such as food processing and clean facilities where hygiene is paramount, HSS tubes are an optimal choice because their minimal surface area attracts less dust and debris.

HSS tubes find their way into many types of equipment typical in the agriculture industry including sprayers, tractors, harvesters, combines, and other equipment. They are also found in frames, cranes, greenhouse structures, and roll-over protective structures.

In addition to providing strength with less weight and easier handling, it is also suitable for many industries and applications due to its ease of fabrication. HSS steel can be formed, cut, punched, flared, flanged, and joined to other shapes through forming, welding, or other mechanical means.

For square and rectangular tubing, the radius of any outside corner may not exceed three times the nominal wall thickness.

Reduced cost does not mean reduced quality. Constructed from cast iron with a cross-braced column, these are ridgid boring mills that are made for heavy duty precision cutting. Large linear rails with heavy duty roller carriages and linear scales provide a precise, low friction system that can withstand high thrust. Machine stiffness is further enhanced by the 10 ton hydrostatic table, which offers 360 degree clamping. Meanwhile, the electronically-counterbalanced headstock delivers a superior contouring performance.

The Giddings & Lewis PT Series of horizontal boring mills are ideal when high flexibility is required to process a wide range of parts.

HSS SteelPrice

HSS tube sizes range from 1 inch to 24 inches in diameter, and these size tubes come in various shapes such as round, square, rectangular, oval, and angle. It is typically made from A500 Grade B, but it can also be made from other grades of steel. HSS tubes are often used for structural support in buildings, bridges, and other large constructions, as well as for decorative elements such as railings.

High speedsteelproperties and uses

HSS tubes are available in a variety of shapes, sizes, and thicknesses, making them versatile and suitable for a wide range of applications. They can be used to create complex shapes and structures, such as arches and trusses.

Offering fully automatic tool changing capabilities, these machines are highly efficient and have minimized part machining cycle time. A good investment, they deliver high productivity with a low cost of ownership.

HSS tubes are made of high-strength steel, which makes them stronger and more durable than other types of tubes. They can withstand heavy loads, harsh weather conditions, and other external factors.

Engineered to offer superior stiffness and thermal stability, this machine can make accurate, heavy cuts to produce parts for bulldozers, cranes, power generators, mining shovels, airplanes and oil rigs.

High speedsteelproperties

HSS tubes come in a variety of standard sizes and shapes, which are specified by various standards organizations. The most common standard that specifies HSS sizes is ASTM A500 Grade B. Here are some of the most commonly stocked HSS tube sizes available:

Rectangular jumbo HSS is commonly used in welded steel frames that experience loading from multiple directions. Typically available in both A513 mechanical tube and A500 structural tube, the flat shape of rectangular HSS is ideal for construction and often utilized to create visually pleasing aesthetic effects.

HSS tubes are also available in square, rectangular, and oval shapes in addition to round tubes. For square, rectangular, and oval tubes, the outside measurements are taken across opposite sides and then averaged to determine the nominal size.

Twist is measured by holding down the edge of one end of a square or rectangular structural hollow on a surface plate with the bottom side of the tube parallel to the surface plate, and noting the height that either corner on the opposite end of the bottom side is above the surface plate.

Kloeckner Metals is a full-line hss tubing supplier and service center. Download our steel pipe and steel tube spec sheet and check what Kloeckner Metals routinely stocks.

What is HSSin government

The Giddings & Lewis FT 3500 is a large precision boring mill, designed for the most demanding applications in heavy industry.

HSS tube sizes are measured by their outside diameter and wall thickness, which are referred to as the nominal size. HSS tubes come in a wide range of sizes, from small to very large.

Giddings & Lewis boring mills are widely recognized as the most rigid and precise machining platforms in the industry. With unrivaled accuracy and the ability to meet the tightest tolerances, these machines deliver the highest possible quality results, every time. Not sure which one is right for you? Our expert engineers will work with you to find the perfect solution from our flexible, modular range.

The hollow shape of HSS tubes reduces their weight compared to solid steel sections, making them more cost-effective to transport and easier to handle on the job site.

The Giddings & Lewis FT 3500 has an entirely modular design, which means you can select the features and capabilities you want, based on your application requirements.

With a one-piece column base and bed, these rigid machining platforms deliver exceptional stiffness for precise, heavy cuts. Accuracy is further enhanced by the capability to probe with either the main spindle or an auxiliary probe. These machines are ideal for industries such as oilfield, defense, aerospace and construction, where high precision in the boring of large workpieces is crucial.

The Giddings and Lewis MC Series of horizontal boring mills offers the ultimate performance in automated large part production.

HSS tubing is also available in A36 Grade 50, which is a hot-rolled form of carbon steel. Due to its versatility, strength, and formability, A36 Grade 50 steel is used in a wide variety of applications.

Common HSS tube steel sizes are 1/2 inch square to 12 inches square and from .188-inch wall thickness to 0.5-inch wall thickness. When selecting HSS tubes for a project, you must consider the size of the tube as well as the grade of steel.

Overall, HSS tube offers several advantages over other types of structural elements, making them a popular choice in many industries.

HSS tubes with rectangular shapes (including squares) have around 33% less surface area compared to an open section with similar capacity. This translates to reduced surface preparation, less usage of painting materials and labor, and lower requirements for cementitious fireproofing.

Typically, round HSS tube is available in A513 mechanical tube and A500 structural tube. It is useful in creating uniform shapes, especially for constructing columns, and is highly resistant to torsion.

A modular set up means that you can choose the features and capabilities that you need for your individual production process.

In addition to the standard boring mill live spindle, the large, heavy-duty Giddings & Lewis FTR 3500/5000 models have a rectangular ram for extended reach and rigid cutting performance capabilities.

Designed with a modular setup, you can choose from three different headstocks (two or four-speed, 130 or 155 mm diameter). Capabilities can be expanded with the addition of rotary tables or attachments, such as contouring heads and programmable boring bars.

HSS tubes can be left exposed in buildings, bridges, and other structures, creating an industrial, modern, and aesthetically pleasing look.

The Giddings & Lewis RT 1250/1600/2000 models are robust, heavy duty boring mills with a substantial weight capacity. They can handle any part weighing up to 40,000 kg.

Flexibility is a key feature of these machining centers. The machines are crafted with an entirely modular design, so we can work with you to create a custom machine that combines the features and capabilities that you need, based on your application requirements.

It’s important to note that the sizes listed above are not an exhaustive list and that other sizes may be available depending on the manufacturer and the specific application. Additionally, HSS tubes are typically available in various wall thicknesses, which can affect the load capacity and rigidity of the tubing.

The Giddings & Lewis T-Bed 130/155 boring mills offer high flexibility and can be customized to meet your individual machining requirements. A variety of attachments and probes are also available to further increase versatility.

HSS tubes are used in the construction of sports equipment such as basketball hoops, soccer goals, and fitness equipment due to their strength and durability.

HSS is commonly used in columns, buildings, towers, signs, and awnings. HSS tubes are also used in bridge construction for their high strength-to-weight ratio and durability. They are often used as bridge girders, trusses, and other structural elements.

0086-813-8127573

0086-813-8127573