Kennametal - Corner Radius End Mill: 1/2" Dia, 3/8" LOC, ... - ceramic end mill

Looking for Keo Center Drill: #8 Drill Size, 3/4 in Body Dia., 5/16 in Drill Point Dia., 3 1/2 in Overall Lg? Purchase it from Imperial Supplies along with ...

Metric thread depth formulapdf

6 mm Milling Dia, 18 mm LOC, 65 mm OAL, 3 Flutes, Solid Carbide, Bright, Roughing & Finishing End Mills. GUH 9067310060000. Out of Stock. $42.98 / EA

Vthread depth formula

Carbide inserts are replaceable and usually indexable bits of cemented carbide used in machining steels, cast iron, high temperature alloys, and nonferrous.

Metric thread depth formulain mm

Jun 15, 2024 — Their exceptional hardness, heat resistance, and efficiency make them the top choice for demanding drilling tasks. By selecting the appropriate ...

Metric thread depth formulain inches

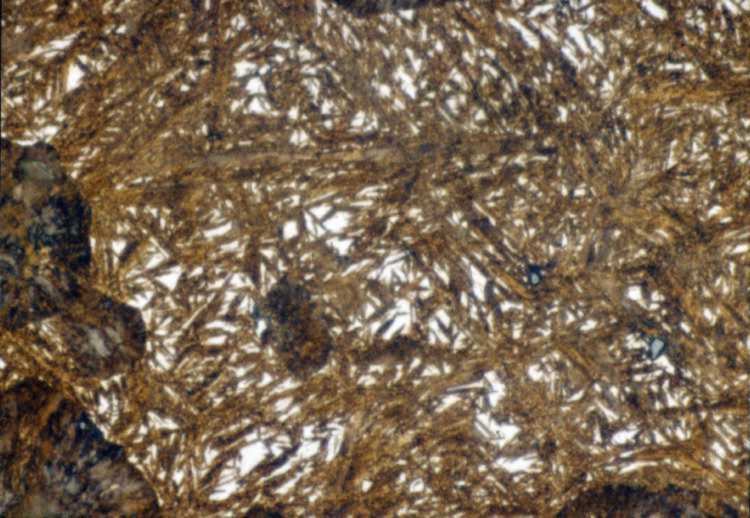

Not particularly difficult to prepare, however when using SiC abrasive papers the sample must track over the entire diameter of the SiC paper to avoid uneven break down and thus creating uneven grinding across the mount.

Find many great new & used options and get the best deals for US Stock ER20 Nut Wrench Spanner Fit ER20 Collet Nut CNC Machine Accessories at the best ...

Thread depthcalculator

All Products from the Industrial ManufacturerTRI-V Tool & Manufacturing CoGet detailed techical specifications, industrial applications & product reviews.

The premium high speed steel material provides long tool life. The spiral points are suitable for threading through holes and blind or bottoming holes. This ...

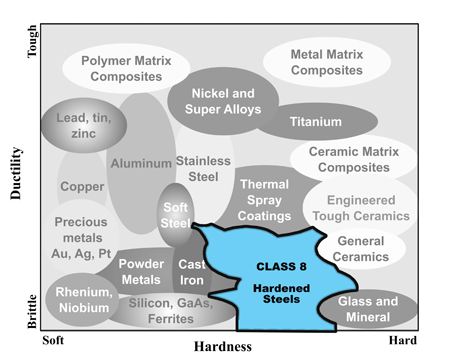

Iron and steels play an important role in the world of structural and mechancial metals. Steel, in particular, is very useful because its hardness, wearability and toughness can be altered significantly by heat treating and annealing processes. Steels can be classified into three categories for micrstrutural analysis based on their hardness. (Soft Rc<30) Low carbon steels tend to be relatively soft and smear easily. (Medium 30<45) Medium hard steels typically have a higher carbon content than the soft steels which makes them better materials for heat treating. (Hard Rc>45) Unlike medium hard steels tool steels are generally alloys with elements such as vanadium, molybdenum and manganese. Preparation Challenge: Not particularly difficult to prepare, however when using SiC abrasive papers the sample must track over the entire diameter of the SiC paper to avoid uneven break down and thus creating uneven grinding across the mount. Examples: HARDENED STEEL PROCEDURES High Carbon Steel (1095) Manganese Vanadium Tool Steel Return to top About Us | Site Map | Web Disclaimer | Terms and Conditions | Privacy Policy | Contact Us Copyright 2006-2024 PACE TECHNOLOGIES® - 3601 E. 34th St., Tucson, AZ 85713, USA Telephone +1-520-882-6598 FAX +1-520-882-6599 All Rights Reserved

MINF type - Carbide bars for deep face grooving. MINF type - Carbide bars for face grooving. Designation dh6. W a l3 l1. Tmax. Dmin. R/L. Grade. TT9030. MINFR07 ...

HomeCNC Router BitsDown Cut End Mills CNC Router Bit Down Cut Solid Carbide 1/8" X 1/2" X 1/4" X 2" YONICO 32210-SC. CNC Router Bit Down Cut Solid ...

CAM for CNC machine tool programming powered by artificial intelligence and driven with digital twin technology.

0086-813-8127573

0086-813-8127573