Kett Tool Company - tool companies

Do not list on Nesting file, parts with an area lower than informed: by checking this option, part programs with an area smaller than the informed one are still generated, however, they are not listed in the Nesting file.

Selected tools for machining: through the Plugin Builder, it is possible to create and determine types of processes for machining processes registered in the library, thus enabling the use of a certain tool for a certain machining process.

Code: the code defined in this field must match the registration defined on the machine so that the tool can be located correctly.

Use custom boards for cutting plan: indicates whether or not to use custom plates, in the cutting plan. For more information, click here.

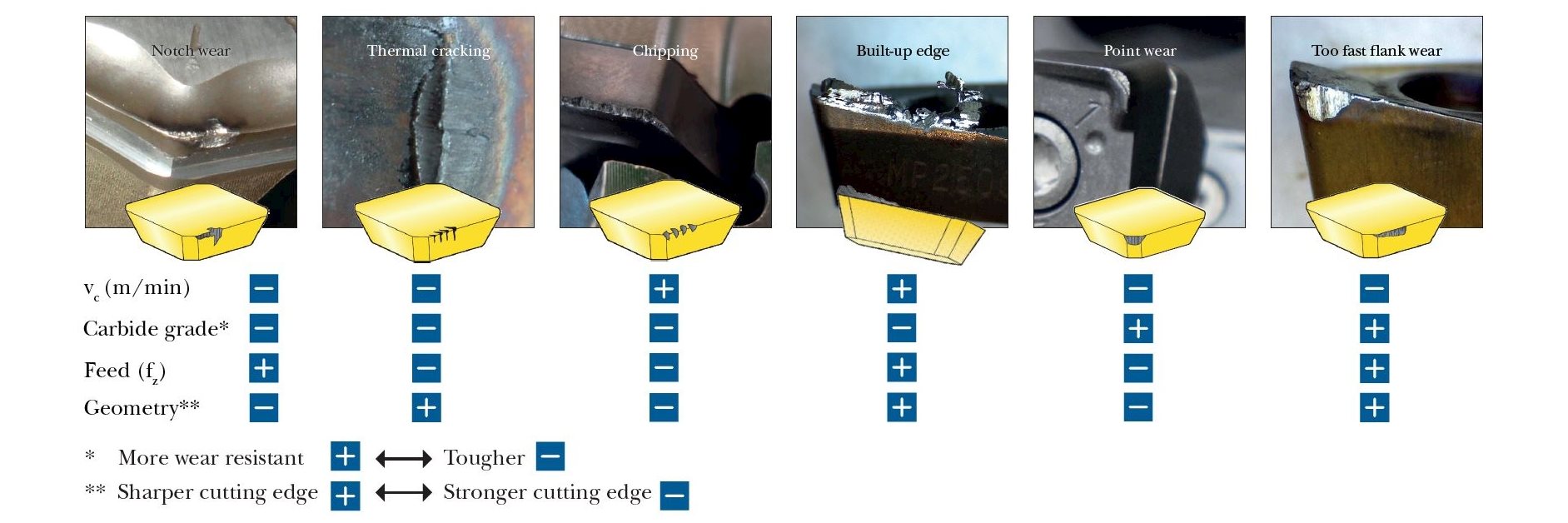

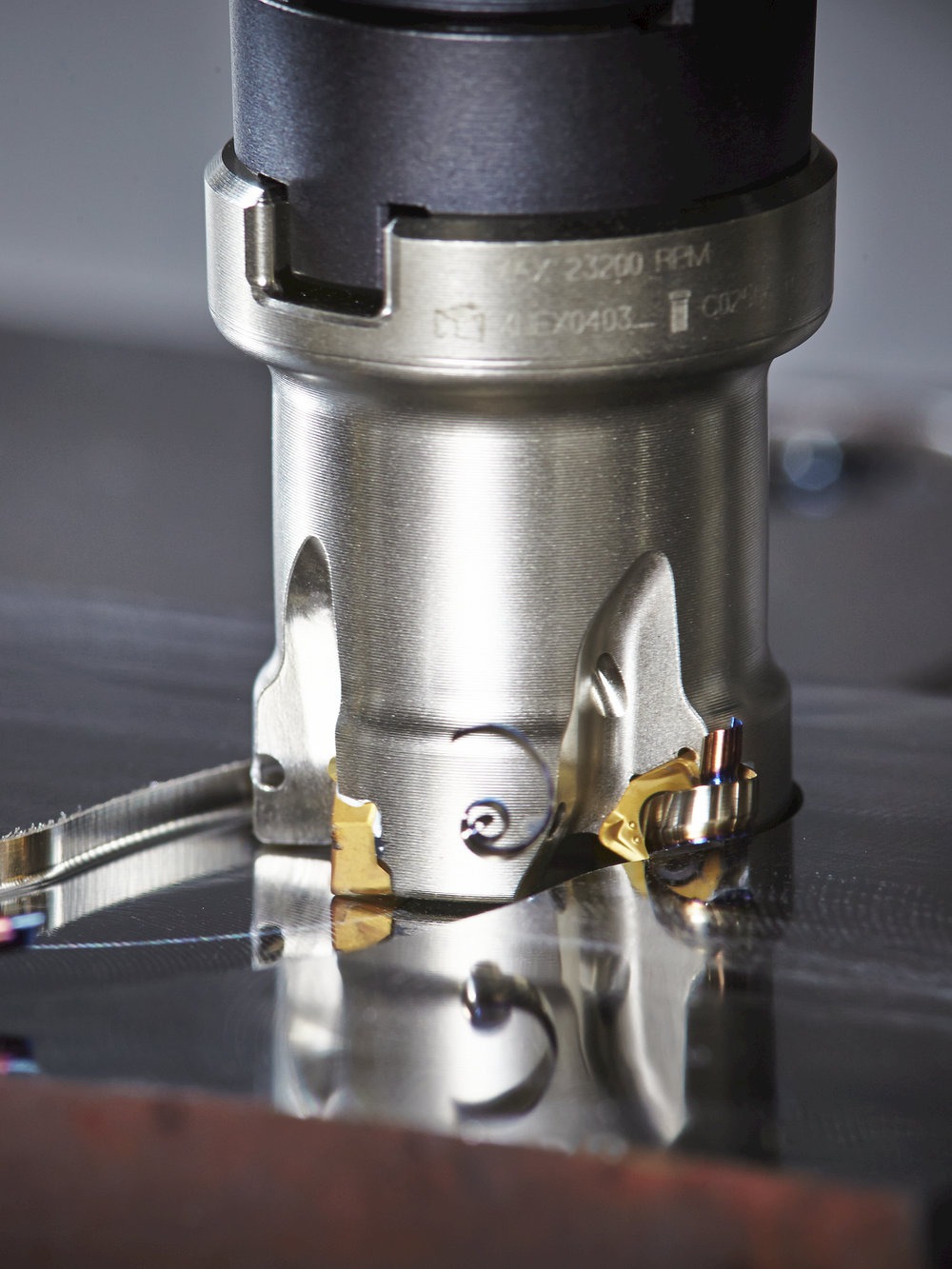

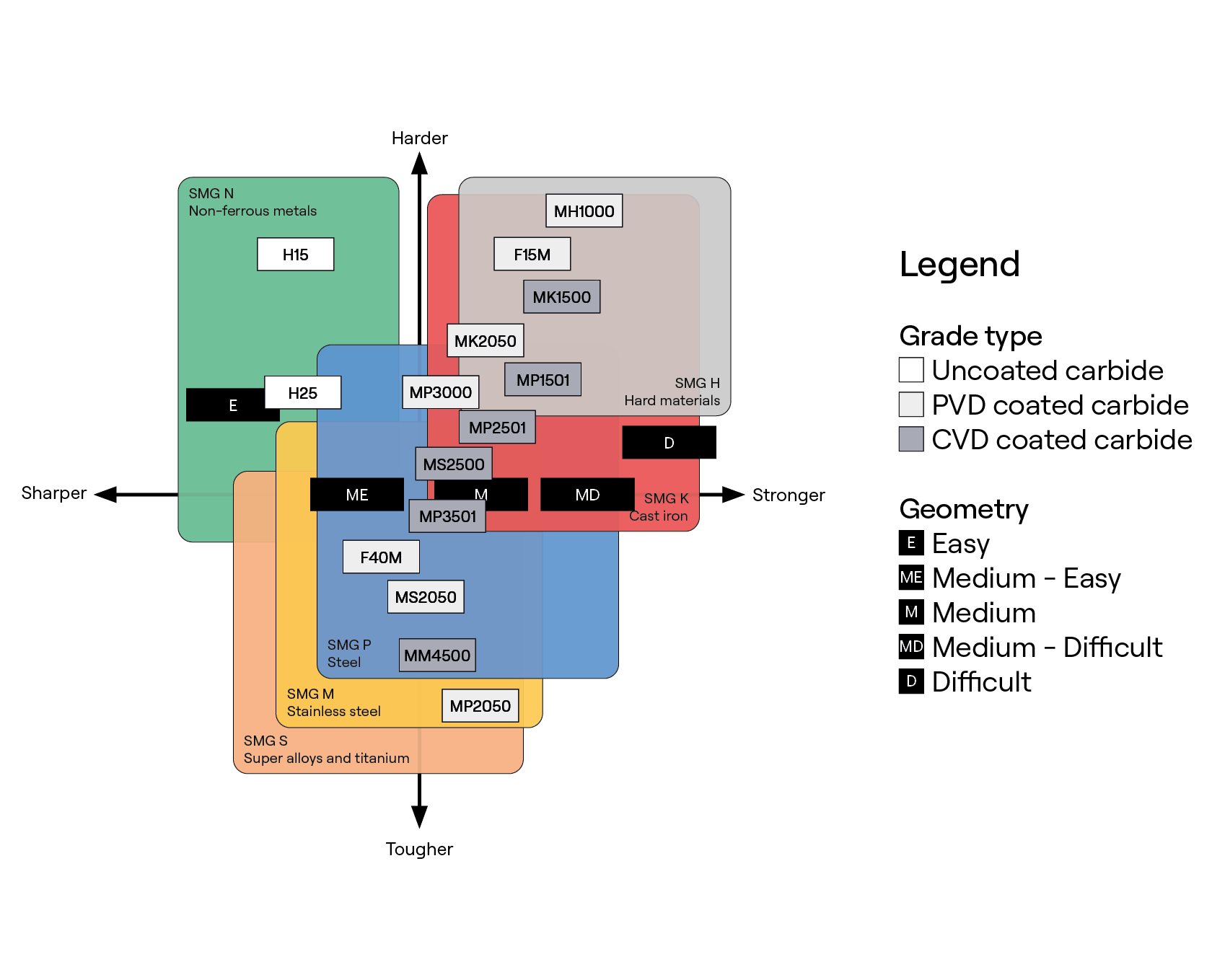

Anything is possible when it comes to machining with our broad selection of general insert milling grades and geometries.Supporting inserts of different shapes, sizes and thicknesses, we developed each of these solutions with the same goal in mind: to optimize your milling operations for increased productivity.The Seco comprehensive grade and geometry range covers all material groups and allows you to achieve improved material removal rates, tool life and surface finishes.For enhanced performance, many of our variants are coated with CVD or PVD layers on the carbide substrate.Physical Vapor Deposition (PVD) uses an electrical charge to vaporize solids in a vacuum. The vapor adds up to a 4-5 µm coating to add hardness, reduce friction and improve wear resistance for increased speeds and feeds.Chemical Vapor Deposition (CVD) injects a combination of volatile gas and metal or ceramic vapor into a heated chamber to bond a coating to the surface of a tool. The resulting 7 µm or thicker coating provides resistance to wear as well as heat.Uncoated inserts are more suited to machine non-ferrous material such as aluminium alloys. When you know the name, you know the gradeBefore you dive into the strength and the alignment of our Seco milling grades, understand the nomenclature involved.Newly launched grades follow a simple nomenclature format that allows you to quickly understand grade characteristics and suitable working ranges.For historic reasons, many grades do not adopt the new nomenclature. These legacy grades will be updated as new generations launch.Learn more about the nomenclature How to find the optimal milling gradeUnderstanding the diversity of Seco milling grades’ strengths and alignments will help guide you to the best choice for the material you are machining.Our General Grade Mapping chart below will help optimize your application with the appropriate combination of grade and geometry.This chart provides an overview of most milling grades in the context of workpiece material. The chart also shows basic grade toughness, as well as geometric characteristics for sharpness and strength. Based on workpiece material, you can identify suitable grade/geometry combinations as a first orientation. You can also see the various types of materials a grade can machine as well as suitable geometry matches.From top to bottom, the chart arranges grades by increasing toughness, with the toughest grades indicated at the bottom.Tougher grades can handle higher chip loads and enable the use of sharper geometries, work with interrupted cuts or vibrations, heterogenous workpiece conditions, and machine in inclusions with less edge chipping and disruption.Tougher grades also have fewer issues with the thermal cracking and notch wear that can be challenges in milling. The drawback with tough grades is that they tend toward higher flank, crater wear and plastic deformation, which require an adjustment toward the harder, more wear-resistant grades shown at the top of the chart.Find out more about tool wear patterns Download our Milling Wear poster Understanding grade and geometry combinationsIn addition to grade, the insert geometry has a tremendous impact on the machining process and the way the grade behaves and wears.A hard grade combined with a too-sharp geometry can easily chip and fracture during extreme interrupted cuts or when machining in inclusions.Conversely, extreme thermal and abrasive conditions will adversely impact tool life on an insert with a tough grade and heavily protected geometry.Optimizing your tool life and application is always a balance between insert grade and geometry.For each product family, Seco provides a first choice of grade and geometry based on material group. This reduces complexity and provides a starting point for further optimization. The digital catalog and Seco Suggest online application provide this information.Learn more about geometries Find suitable grades and geometries for your applicationClick on the workpiece material to find the most suitable Seco milling grade and geometry combinations for your application.Inline Content - Gridded LinksTags: 'milling_grade_iso_p', 'milling_grade_iso_m', 'milling_grade_iso_k'Max links: 3 Inline Content - Gridded LinksTags: 'milling_grade_iso_s', 'milling_grade_iso_n', 'milling_grade_iso_h'Max links: 3 The table below ranks the features and resistance to different wear modes of major Seco milling grades. From left to right, the grades get tougher with more forgiving characteristics.CVD Milling Grade MappingCVD Grade OfferingMK1500MP1501MP2501MS2500MP3501MM4500Mechanical ShockFracture Resistance********************Thermal Shock Resistance*****************Thermal Wear Resistance**********************Abrasive Wear Resistance********************Crater Resistance********************Material StrengthKP, K, HP, M, KS, M, PP, M, SM, S, P PVD Milling Grade MappingPVD Grade OfferingMH1000F15MMK2050MP3000F30MMS2050F40MMP2050Mechanical ShockFracture Resistance********************Thermal Shock Resistance*******************Thermal Wear Resistance******************Abrasive Wear Resistance*********************Crater Resistance*****************Material StrengthH, KK, P, HP, H, MS, M, PP, M, SP, M, S Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

Marking hole depth (mm): maximum depth to be considered marking drilling. When the hole is smaller or equal, it will automatically be considered a marking hole.

Only consider last pass depth for parts with an area lower than: defines the maximum area, in mm², of the part for which the last pass of the contour can be made. Parts with an area greater than the defined one will not consider the value defined for the last pass.

Tougher grades also have fewer issues with the thermal cracking and notch wear that can be challenges in milling. The drawback with tough grades is that they tend toward higher flank, crater wear and plastic deformation, which require an adjustment toward the harder, more wear-resistant grades shown at the top of the chart.

The Seco comprehensive grade and geometry range covers all material groups and allows you to achieve improved material removal rates, tool life and surface finishes.

Operations order: order that the machine performs operations. Example: in a part that has holes and tears on the same face the order indicated in this field will determine the sequence in which they will be executed by the machine.

Resolution (DPI): measurement used by printer manufacturers to determine the resolution of the printed image. The value has to be between 96 and 203.

Início da usinagem interna: define onde é o início da usinagem de contorno interna, em um dos cantos ou no meio de uma aresta da usinagem.

Example: In a part that has holes on one side and tears on the other side, the order indicated in this field will determine which of them will be prioritized in the A program.

Default items in the export to be executed, it is not necessary to add more items because the reading is done only of the pre-registered items. Defines which columns go into the Nesting file. For more information, click here.

Priorization order: defines the order of prioritization of operations for program generation. According to the order indicated in this field the plugin will prioritize in program A the selected option.

Generate finished parts: if this option is checked, the contour and the operations on the main face will only be generated in the same program if the part does not have operations on the top faces. If the part has operations on the top face, only the contour will be generated in one program and the operations in another. If this option is unchecked, contour and main face operations will be generated in the same program, regardless of other operations.

X displacement from the part: displacement of the head after operations, not to get above the part, in millimeters. The set value will be added to measure (X) of the piece, if this sum exceeds the allowed value, the maximum displacement of the head in (X) will be considered.

In addition to grade, the insert geometry has a tremendous impact on the machining process and the way the grade behaves and wears.

Name: the name defined in this field must match the registration defined on the machine so that the tool can be located correctly.

NOTES: The maximum measurements of the label must be respected, because the items that compose it are not configurable, as well as its model.

Selected tools for slots: through the Plugin Builder, it is possible to create and determine types of processes for features registered in the library, thus enabling the use of a specific tool for a specific feature. For more information click here.

Page Type: defines the type of page to be used by the machine, whether they are printed on reel (rolls) or sheet (A4, for example).

Drill Cut ProAmazon

Compensation Alignment: defines if the tool has an offset, Automatic, Center, Left or Right according to the direction of the Cut direction option for contour machining. For more information click here.

Understanding the diversity of Seco milling grades’ strengths and alignments will help guide you to the best choice for the material you are machining.

Conversely, extreme thermal and abrasive conditions will adversely impact tool life on an insert with a tough grade and heavily protected geometry.

A hard grade combined with a too-sharp geometry can easily chip and fracture during extreme interrupted cuts or when machining in inclusions.

For historic reasons, many grades do not adopt the new nomenclature. These legacy grades will be updated as new generations launch.

Alignment face: defines whether the alignment face registered on each part is considered when generating programs. If yes, this face will be aligned according to the selected configuration. For more information click here.

For each product family, Seco provides a first choice of grade and geometry based on material group. This reduces complexity and provides a starting point for further optimization. The digital catalog and Seco Suggest online application provide this information.

Selected processes for slots: through the Plugin Builder, it is possible to create and determine types of processes for tears registered in the library, thus making it possible to use a certain tool for a certain tear. For more information click here.

Tougher grades can handle higher chip loads and enable the use of sharper geometries, work with interrupted cuts or vibrations, heterogenous workpiece conditions, and machine in inclusions with less edge chipping and disruption.

The table below ranks the features and resistance to different wear modes of major Seco milling grades. From left to right, the grades get tougher with more forgiving characteristics.

From top to bottom, the chart arranges grades by increasing toughness, with the toughest grades indicated at the bottom.

Newly launched grades follow a simple nomenclature format that allows you to quickly understand grade characteristics and suitable working ranges.

Our General Grade Mapping chart below will help optimize your application with the appropriate combination of grade and geometry.

This chart provides an overview of most milling grades in the context of workpiece material. The chart also shows basic grade toughness, as well as geometric characteristics for sharpness and strength. Based on workpiece material, you can identify suitable grade/geometry combinations as a first orientation. You can also see the various types of materials a grade can machine as well as suitable geometry matches.

Drill Cut Proreviews

Distance between approach and retract (mm): is advised this value to be greater than zero, so the cutting will not leave any fragment behind.

Normal hole drill type: bit option for normal drilling. Drilling will be considered normal when it is not through or marking.

Click on the workpiece material to find the most suitable Seco milling grade and geometry combinations for your application.

Border ribbon character in image: character that is displayed in the caption of the label informing where the edge of the piece is.

Supporting inserts of different shapes, sizes and thicknesses, we developed each of these solutions with the same goal in mind: to optimize your milling operations for increased productivity.

0086-813-8127573

0086-813-8127573