Key Cutting - Calgary - key cutters

Our screw-on negative rake end mill cutters are configured with 2, 3 or 4 flutes. These are fitted with our 4 cutting edge insert to machine alloyed steel or cast iron, offering extended life and high performance cutting.

A critical feature in twist drills, helix angles determine the process of chip formation. Large helix angles are good at removing soft, long-chipping materials. Small helix angles are good for the removal of hard, short-chipping materials. Note that there is some overlap in how helix angles are categorized.

TungstenCarbide Drill Bits

High-Speed Steel (HSS) is the most popular drill bit material for several reasons. High-Speed Steel is readily available, and we have plenty of it right here in the United States. HSS is also extremely versatile. Manufacturers can configure an HSS drill bit for just about any application you can think of.

Chain Headway shank mounting high feed negative rake end mill cutters are available with between 2 and 5 flutes depending on size. Our shank mounted end mill cutters accept our 4 cutting edge insert for machining hard alloys and cast iron.

Solid Carbide drill bits are the most expensive but they will outlast other drill bit materials by a longshot. A Carbide drill will outlast a Cobalt drill by at least twenty times, reducing the cost-per-hole significantly.

Carbide drills allow for a Through Spindle Coolant system or TSC as it’s known. In situations where you’re drilling deep into very hard materials, the feeding of coolant through the drill allows for better chip evacuation and self-cooling. This also helps to prevent wear, which is nice since TSC drill bits are pricey.

The NAC 45° milling cutter features between 4 and 12 flutes depending on size, and is designed to accept our negative rake angle insert with 8 cutting edges. This design can remove bulk material rapidly and with more depth of cut than the 12 cutting edge insert, making it suitable for rough machining, but with an improved surface finish compared to positive rake angle cutters.

This shell milling cutter is ideal for semi-finish machining and rapid removal of material while maintaining a high-quality surface finish.

Carbide drill bitsfor hardened steel

If you have any questions at all, please feel free to reach out to our team at (833) 4-ETOOLS. You can also email us at sales@eldoradotools.com.

The core business of Chain Headway is the in-house design and manufacturing of CNC cutting tools. Our long experience of designing and supplying high quality CNC cutting tools for customers from different industries has made us experts in matching tools to customer requirements and production practices, and has driven our expertise in tool insert manufacture.

Geometry is just as important as the material and coating when it comes to the performance and characteristics of a drill bit. Consider that every manufacturer has its own proprietary configurations so we’ll just focus on the general aspects.

Cobalt Drill bits

Throw a good coating on any drill bit and you’ll completely change its characteristics. Coatings extend tool life and improve cutting performance. We’ve selected a few of the most popular coatings to keep things simple, so let’s jump in.

One characteristic of Carbide is that it’s brittle, so it won’t flex. This makes Carbide a bad choice for hand drilling. If you’re running a CNC or frequently use a drilling press, this material is worth the investment.

Discover Chain Headway’s CNC Diamond Brushes at EXPOMAQ 2024 in Mexico. Learn how our advanced diamond brushes enhance surface roughness, deburring, and polishing for metalworking.

Chain Headway shell-type high feed negative rake end mill cutters come in 6 and 8 flute configurations, also designed to be fitted with our 4 cutting edge inserts for precision end milling of hard alloys.

M42 Cobalt is high-speed steel with 8-10% Cobalt added in order to increase the hardness and endurance of the tool. You can pretty much expect the same characteristics as a standard HSS drill, but with increased performance across the board.

Cobalt vs carbide drill bits vstungstencarbide

There are actually a handful of drill point angles, but 118º and 135º are the two most common. A 118º drilling point is commonly put on lower-cost, general-purpose drill bits. It’s suitable for mild steel, aluminum, and other soft metals. On the other hand, 135º is for hardened steel and other tougher materials.

This is an excellent and underappreciated feature in twist drills. A split-point drill bit prevents walking when starting a cut. Without a split-point, technicians would first need to drill pilot holes or use punches in order to start their cuts. This would, of course, take a lot more time and cut into your bottom line.

Carbide DrillSet

Cobalt vs carbide drill bitsfor steel

A shorter drill bit is more rigid which is ideal so you should always use the shortest drill possible. That said, sometimes you have to use a longer drill bit. In these instances, you should at least use the shortest flute-length (cutting portion) possible. Using a drill with an unnecessary long flute length means that you’re choosing to use a less stable drill. This is not advised. The next question to ask is, “How much flute length do I need?” The rule of thumb for determining this is to take the diameter of the drill bit, double that, and then you’ll have the minimal flute length needed above the hole for proper chip evacuation.

As we said earlier, every manufacturer has its own special sauce when it comes to drill bit design but the high-level points we covered here are universal. We hope that this condensed guide will serve as a foundation and help you understand what to consider when choosing the right drill bits for your upcoming jobs.

Black Oxide finishes increase lubricity which helps to resist damage from heat and corrosion. Naturally, this also extends the life of the tool. These bits are best for use on ferrous metals.

Explore Chain Headway’s advanced side milling cutter series at IMTS 2024. Discover versatile, high-precision solutions for diverse machining needs.

We're an online retailer, headquartered in Lakeway, Texas. With fulfillment centers distributed throughout the United States, we guarantee fast delivery!

Cobalt vs carbide drill bitsreddit

Black and Gold finish drill bits resist corrosion and breakage while increasing lubricity. These bits are not prone to chipping and flaking.

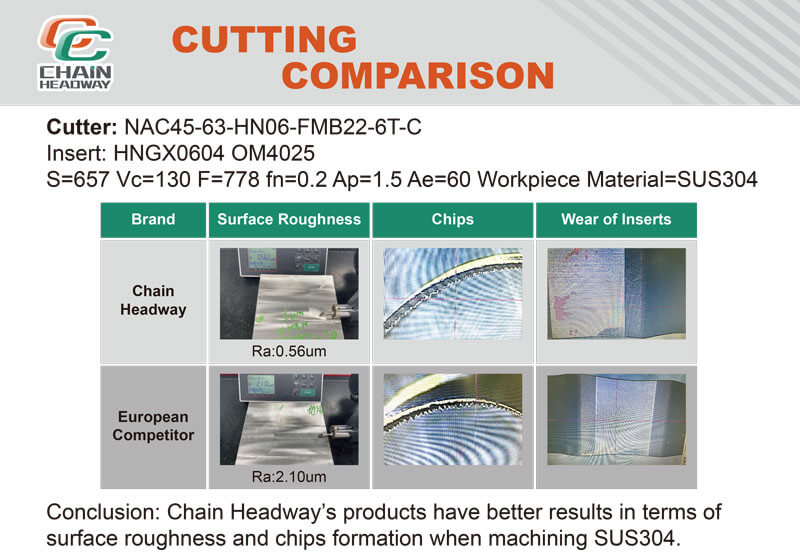

Chain Headway manufactures negative rake angle shank, screw-on, and shell milling cutters to meet any requirement you may have. Comparative tests demonstrate that Chain Headway negative rake angle milling cutters can be used for precision surface finishes, and offer the highest levels of performance available on the market today.

When it comes to choosing the right drill bit for the job, there are three things to consider; material, coating, and the geometry of the tool. We’ll break it all down in a concise way to help clear things up to save you some time.

Titaniumvs carbide drill bits

Our milling cutters come in three ranges designed for three types of interchangeable negative rake angle inserts. Our negative rake angle inserts enable cutting and milling of hard materials to the highest standards. Cutter inserts are designed to be rotated when worn to use fresh cutting edges for significantly extended life.

At Chain Headway we have a deep understanding of cutting tool requirements for different machining operations. Because we manage all our design and manufacture in-house, we are able to rapidly respond to customer requests for in-depth technical advice and support. Please contact us to discuss how our negative rake angle cutters can meet your specific needs.

AlTiN is a couple of steps up from TiN, with extended life and performance. An interesting charismatic is that these do not perform well on aluminum since aluminum is part of the coating.

Skinny drill bits snap more easily than thick drill bits. This is where spending a little more money for heavy-duty geometry is nice. That said, there is much more to drill design than the thickness and it’s not always a priority but it is a nice thing to be aware of.

The first thing to think about is the composition of the drilling bit. There are three popular composites and they all serve a different purpose.

Our NAC 45° Negative Shell Milling Cutters are available with two different insert types, providing either 12 cutting edges (HN..0604) or 8 cutting edges(SN..1206).

The Chain Headway BR Milling Inserts are the ideal choice for addressing surface polishing and contouring needs in the production of large ship anchor hooks.”

If the angle between the cutting edge and the machined surface is greater than 90° this is a positive rake angle, a negative rake angle occurs when the angle is less than 90°. Negative rake angles put less stress on the cutting edge and are often better for rapid material removal than positive rake angles. Negative rake angle is preferred for machining hard and brittle materials including stainless steel and titanium.

The NHF series of High Feed End Mill Cutters offer high productivity and machining efficiency in three different configurations, and have design features that make them ideal for high feed operations.

0086-813-8127573

0086-813-8127573