Keylocking Threaded Inserts - acme threading inserts

Flutes are the easiest part of the end mill to recognize. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge.

Hi, can Harvey provide some information on and details about Clearance angle, rake angle, and number of flutes together with some parameter of the geometrical features ?

Small HandDrillfor Crafts

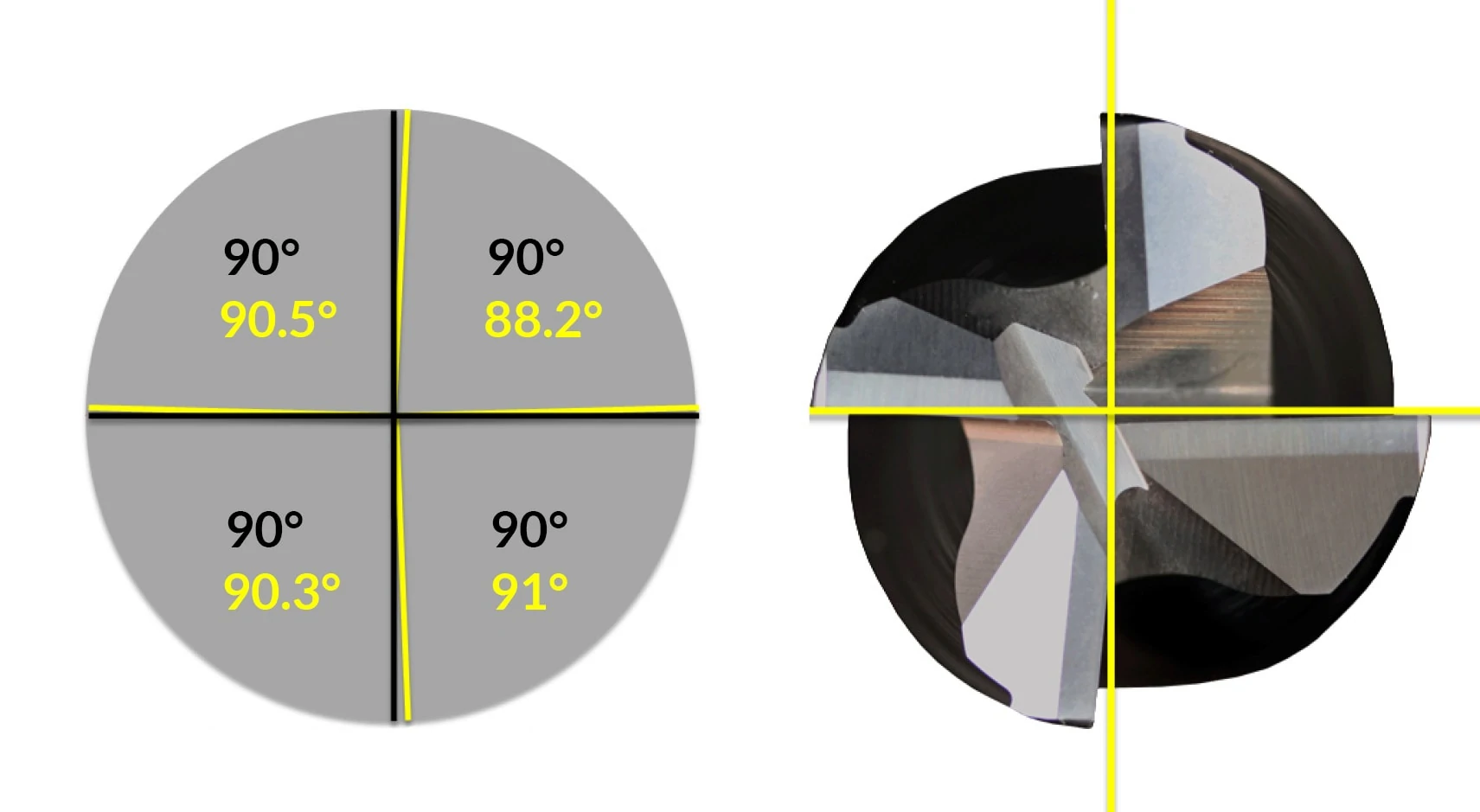

Pitch is the degree of radial separation between the cutting edges at a given point along the length of cut, most visible on the end of the end mill. Using a 4-flute tool with an even pitch as an example, each flute would be separated by 90°. Similar to a variable helix, variable pitch tools have non-constant flute spacing, which helps to break up harmonics and reduce chatter. The spacing can be minor but still able to achieve the desired effect. Using a 4-flute tool with variable pitch as an example, the flutes could be spaced at 90.5 degrees, 88.2 degrees, 90.3 degrees, and 91 degrees (totaling 360°).

When it comes to a lower helix removing chips faster, we tend to disagree. As a helix becomes shallower, the vertical forces on each chip become less and are therefore unable to lift chips as quickly. As a helix becomes less and less, there is less lifting force on the chips and they are moved vertically at a far slower rate. A higher helix will actually lift chips more than a lower helix.

If you give our tech team a call, we’d be happy to help you with any tooling question you might have. You can reach us at 800-645-5609.

A moderate helix angle of 40° would result in a tool able to perform basic roughing, slotting, and finishing operations with good results. Implementing a helix angle that varies slightly between flutes is a technique used to combat chatter in some high-performance tooling. A variable helix creates irregular timing between cuts, and can dampen reverberations that could otherwise lead to chatter.

MiniDrillhome Depot

MicroDrillbits canadian tire

This type of tooling breaks up a sharp corner with a radius form. This rounding helps distribute cutting forces more evenly across the corner, helping to prevent wear or chipping while prolonging functional tool life. A tool with larger radii can also be referred to as “bull nose.”

The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. A higher helix angle used for finishing (45°, for example) wraps around the tool faster and makes for a more aggressive cut. A lower helix angle (35°) wraps slower and would have a stronger cutting edge, optimized for the toughest roughing applications.

Anyone make a roughing endmill in the, “reached endmill” style? That would have been super useful in cutting a groove in a group of parts I just did.

I really like how well you went into detail with each of the bits of a mill. I would bet that people only know about the flute, and even then, may not know that it’s called that. As you said, having the proper helix angle would be quite important when trying to go through certain materials as with a wrong angle, you might struggle to cut the material.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

An end mill features many different dimensions that can be listed in a tool description. It is important to understand how each dimension can impact tool selection, and how even small choices can make all the difference when the tool is in motion.

Smallest Drillbit

I just don’t get this. How is the endmill with the higher helix angle going to cut “more aggressively”? An endmill with a lower helix angle should lift the chip further with each revolution. Wouldn’t this make for a more aggressive cut, particullarly when plunging or machining a slot? Please explain.

The profile refers to the shape of the cutting end of the tool. It is typically one of three options: square, corner radius, and ball.

MicroDrillBit

Worldssmallest drillbit story

One consideration that must be made during tool selection is flute count, something we have previously covered in depth. Generally, the lower the flute count, the larger the flute valley – the empty space between cutting edges. This void affects tool strength, but also allows for larger chips with heavier depths of cut, ideal for soft or gummy materials like aluminum. When machining harder materials such as steel, tool strength becomes a larger factor, and higher flute counts are often utilized.

Helical Solutions has two different styles of reached end mills for roughing. We currently have a 3 Flute 45 degree chipbreaker rougher for aluminum and a 4 or 5 flute end mill with knuckle roughers for steel both of these end mills are reached.

Thank you for reaching out. The best way to get an answer would be to send an email to [email protected] or giving our technical support a call at 800-645-5609.

The cutter diameter is often the first thing machinists look for when choosing a tool for their job. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates.

Finally, to provide more clarity on your point that chips must be lifted up through the flutes to be evacuated, this is correct for drills as there is nowhere else for the chips to go. For end mills, especially in low radial engagement situations such as with HEM, chips are ejected radially and are not really getting the chance to move up through the flutes. That small amount of vertical motion will actually be more with a higher helix.

Minidrillcanadian tire

This type of tooling features flutes with no flat bottom, rounded off at the end creating a “ball nose” at the tip of the tool.

Overall length is easy to decipher, as it is simply the measurement between the two axial ends of the tool. This differs from the length of cut (LOC), which is a measurement of the functional cutting depth in the axial direction and does not include other parts of the tool, such as its shank.

We thought you raised a great point about the high helix angle and how it wraps around the tool faster, making for an aggressive cut, and we agree that this could be misleading. We’ll rework this portion to provide more clarity. What we meant was that there are merits to using a high helix tool in an HEM fashion, since a higher helix causes more points of contact between the tool and the workpiece. This helps to provide stability to cut faster, and even provide more stability in thin wall applications. When we say “aggressive,” we’re referring more the nature of a high helix and less its use in HEM, specifically. A higher helix is more aggressive than a lower helix due to higher shear forces on the workpiece, and higher lifting forces, which can get too high in certain workholding situations.

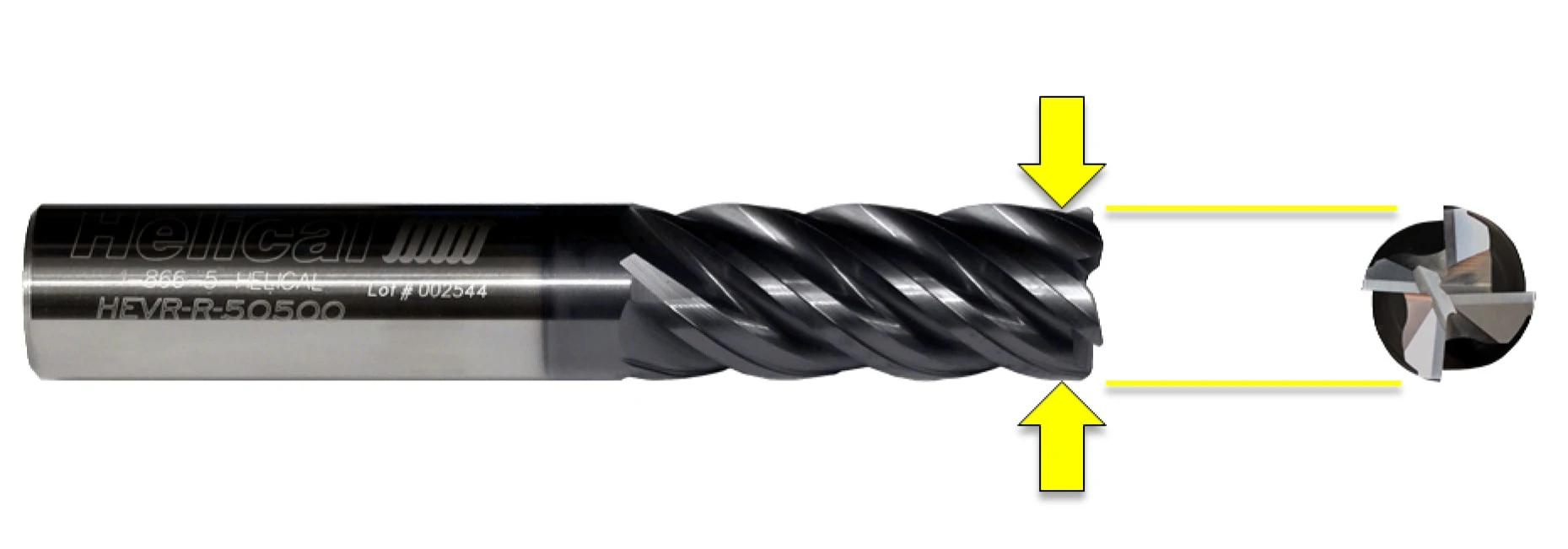

The overall reach of an end mill, or length below shank (LBS), is a dimension that describes the necked length of reached tools. It is measured from the start of the necked portion to the bottom of the cutting end of the tool. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep-pocket milling applications. This is illustrated in the photo below of a tool with a reduced neck.

Smallest drillbit size in mm

The shank diameter is the width of the shank – the non-cutting end of the tool that is held by the tool holder. This measurement is important to note when choosing a tool to ensure that the shank is the correct size for the holder being used. Shank diameters require tight tolerances and concentricity in order to fit properly into any holder.

Not having done very much research into the Variable pitch of Endmills, I just learned a nice little piece of information for my future Milling tasks! I also appreciate the explanation you have given here, great Info for anyone! Thanks again Harvey Tool!

0086-813-8127573

0086-813-8127573