Keyseat Cutters | AB Tools, Inc. | Carbide Cutting and ... - key cutter tool

To access speeds and feeds information for your Harvey Tool product, head to http://www.harveytool.com/cms/SpeedsFeeds_228.aspx to find speeds and feeds libraries for every tool.

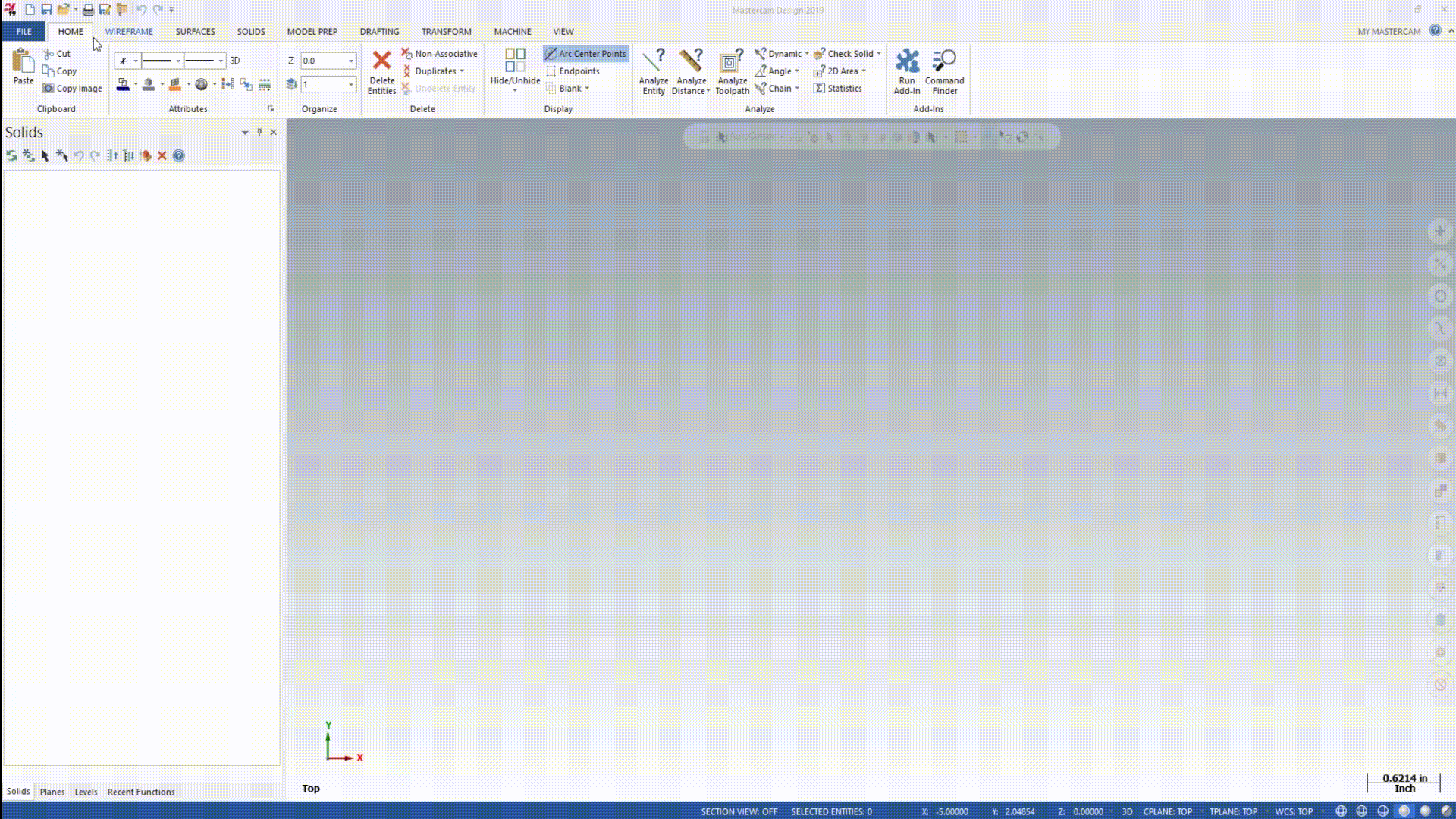

Mastercam gives your shop the best possible foundation for fast and efficient milling and drilling. From general purpose methods, such as optimized pocketing, to highly specialized toolpaths like 5-axis turbine cutting, Mastercam ensures that you’re ready for any job.

To increase throughput and ensure continuous operation, you can integrate dual spindles and multiple tables when machining complex and high-volume composite parts. The dual spindles enable the machine to work on two parts simultaneously, doubling the production capacity without increasing production costs.

2016824 — Thesnarlingbadger ... bluebedouin said: Coca cola is an excellent cleaner for rust & the cheap brands work just as good as the main ones. Second ...

Composite materials are among the most challenging materials, making CNC machining the ideal technology for processing them into desired final products. Although it requires substantial expertise and experience, composite CNC machining allows for extensive design flexibility, precision, accuracy, and superior quality. The relevance of advanced CNC machining grows as composite materials become increasingly prevalent across medical, automotive, defense, marine, and aerospace industries.

You will also be able to sort the library by different tool dimensions like cutter diameter, flute count, and corner radius by clicking on the column headers. If you are looking for a more advanced search, you can click the “Filter” button on the bottom right side of the Tool Manager window. This will bring up a new window where you can filter results by tool profile (square, corner radius, ball), radius type, and more exact cutter diameter values.

The top-selling product within Steel Drill Bits is the Milwaukee SHOCKWAVE Impact Duty Alloy Steel Screw Driver Bit Set with PACKOUT Case (220-Piece). What are ...

If you have further questions about speeds and feeds, please reach out to our Technical Support team. They can be reached Monday-Friday from 8 AM to 7 PM EST at 866-543-5422, or by email at [email protected].

CNC machining materials are often chosen based on their respective cost-efficiency, mechanical properties, and compatibility with the intended application. These advanced materials

Having Harvey and Helical’s end mill libraries available directly within Mastercam will be a huge benefit for Form Factory. We are constantly ordering new unique job specific tools which require us to custom build them into our library. Now, we can go directly to the exact right tool and eliminate this chance for human error. We will even be able to program ahead of the tools arrival to try tool-pathing with different tools and find out what works best BEFORE we buy! This will save us time and money!

Apr 18, 2024 — Chemical Entities of Biological Interest (ChEBI) is a freely available dictionary of molecular entities focused on 'small' chemical ...

To satisfy customer requirements, increase productivity, and reduce waste, it would be best to maintain high-quality standards when CNC machining composites. It would help to conduct regular inspections at different stages of the machining process to identify and correct defects early.

CNC machining composite materials is a critical process that requires a meticulous and systemic approach to attain precision and efficiency. We’ll explore the basic steps in the manufacturing process below:

Since a computer controls the machines, the need for direct human interaction with cutting tools is reduced significantly. Therefore, personnel on the machine floor are safer from machining hazards.

When you have a job which requires dozens of tools to be programmed, it gets to be time consuming. These new tool libraries from Helical and Harvey Tool will be a big time saver for my team and easily allow us to verify our programs within Mastercam.

This guide explores the basics of composite CNC machining, explaining the fundamental properties of composite materials, constituting elements, and types of composites used in CNC machining. Continue reading to learn the basic steps of CNC machining composites, applications of CNC machined composite parts, and best practices for machining composites. Let’s get to it!

To ensure the best possible machining results, we have decided not to prepopulate speeds and feeds information into our tool libraries. Instead, we encourage machinists to access the speeds and feeds resources that we offer to dial accurate running parameters based on their material, application, and machine capabilities.

You can find a direct link to Harvey Tool and Helical tool libraries in the Mastercam Tech Exchange by clicking the “Download” buttons in the webpage above, or by clicking the links below.

Lathe tool bits are used in a variety of woodworking applications like turning & grooving. MSC Industrial Supply offers a selection of lathe tool bits, sets, ...

Using the right tool holder when machining composite helps improve the tool’s stability and ensure the cut’s precision. The tool’s stability helps to reduce tool wear and risk of delamination. Machining experts recommend using hydraulic and shrink-fit holders due to their superior gripping strength and precision. Similarly, employ optimal cutting angles to make clean cuts through the composite layers without pulling or fraying.

Higher spindle speeds ranging from 18,000 to 24,000 RPM are ideal for composite cutting because they reduce chip load without compromising surface quality, ultimately minimizing lead time and ensuring an extended tool life span. Moreover, some spindles provide versatility with adjustable speeds adequate for handling lightweight composite materials at high speeds and heavier, non-ferrous metals at low speeds between 10,000 to 12,000 RPM.

From AT-Machining, I’m a CNC Machining Expert in this field for more than 20 years. We offer cost-effective machining services from China. Ask for a quote for your ongoing or upcoming projects now!

Engineers and machinists can create parts with highly complex shapes that are almost impossible to achieve with other production techniques using CNC machining techniques. Hence, composite CNC machining helps ensure parts are tailored to exact specifications without sacrificing the material’s integrity.

If you have further questions or need support with Mastercam downloads, please get in contact with your Mastercam reseller or visit https://www.mastercam.com/en-us/Support/Technical-Support for more information.

Harvey Performance Company has partnered with Mastercam to provide comprehensive Harvey Tool, Helical Solutions, and Valor Holemaking tool library integrations and technical information to the Mastercam community. Almost 24,000 tools in total, from the three brands’ expansive product offering, is available to download for Mastercam users.

Machininggraphite

CNC machining composite requires specialized tools to manage the unique composite material properties. These CNC tools are carefully selected according to their ability to mitigate damage during machining and improve the final product’s quality. Below are the standard tools used for cutting composite materials:

You can also use a thread mill to back chamfer the hole; Thread milling requires much less horsepower from the machine than tapping; Threadmills are readily ...

T-Handles · Additional information · Product Categories · Find Sub-Category · Latest Posts · Our Clients.

Various factors must be considered before CNC machining composite materials to achieve the desired tolerance and precision. Here are some of the things to keep in mind when CNC machining composite:

Precision CNC machining composite materials help maintain the composite material’s integrity. Therefore, CNC-machined composite parts are more durable and reliable than components manufactured with less precise methods.

Hence, you must consider dust removal mechanisms and systems to maintain a clean work zone, protect help machinists’ health, and ensure the quality of finish, machine longevity, and the tooling involved.

Composite CNC machining offers numerous significant advantages, surpassing traditional manufacturing techniques. Here are some of these benefits:

Another way to download our tool libraries is to head to the Mastercam Tech Exchange by visiting https://community.mastercam.com/techexchange. You will need to be logged in to your Mastercam.com account in order to access the Tech Exchange portal.

If you are looking for tool specific speeds and feeds information, you will need to access the tool’s “Tech Info” page. You can reach these pages by clicking any of the hyperlinked tool numbers across all of our product tables. From there, simply click “Speeds & Feeds” to access the speeds and feeds PDF for that specific tool.

If you need additional support with your Harvey Tool and Helical libraries, think you may have found some dimensional data that needs correcting, or have feedback you want to share with our team, you can get in touch with us by sending an email to [email protected].

AT-Machining is a renowned professional in the composite CNC machining field. Our experts leverage our cutting-edge machinery to devise innovative solutions to meet the demands of your projects. We are committed to delivering CNC-machined parts that meet the highest material standards and dimensional accuracy. Our engineers and quality control experts subject each part manufactured to strict quality control checks to ensure they are all built to specifications and defect-free. Upload your CAD file now to get an instant and reliable quotation!

Manufacturers across industries utilize composite CNC machining to create many products for different applications. Typical applications of composite CNC machining include:

Once you are in the Mastercam Tool Manager, simply click on the folder icon to open your computer’s saved files. Navigate to the folder on your computer where you saved your tool libraries, and select the tool library files you have downloaded to add them to your Mastercam Tool Manager library.

Spindle speed and feed rate are other critical parameters in composite CNC machining because they help maintain efficiency and quality. Although low RPM spindles with high torque might be ideal for heavy-duty metal cutting, they are ineffective when handling composites.

Tool sharpness is critical in CNC machining composite materials due to their abrasive nature and other properties. Sharp tools directly affect the cut’s quality, operational efficiency, and finished part’s surface finish. While dull tools can cause complications such as increased heat, rapid tool degradation, and material tearing, sharp tools reduce friction and tool wear. Therefore, you wouldn’t have to worry about burrs, bind, or kickbacks when machining composites with sharp CNC tools.

Experts recommend machining composite materials with high-quality, precision tools that reduce tools and ensure consistency. Moreover, it would be best to adhere to relevant industry standards and get necessary certifications that attest to the quality and reliability of the machining process.

CNC machines execute different operations at a rapid pace, unlike conventional machining methods. As such, CNC machining composites help manufacturers achieve faster lead times for projects requiring intricate designs and high volumes while increasing productivity.

If you have further questions about speeds and feeds, please reach out to our Technical Support team. They can be reached Monday-Friday from 8 AM to 7 PM EST at 800-645-5609, or by email at [email protected].

Composite CNC machining is a modern manufacturing trend that provides groundbreaking possibilities in material engineering and production efficiency. Composite materials provide extensive potential in advanced technologies and emerging industries due to their unique properties and varying combinations. Understanding the specific requirements of CNC machining composite materials is essential to make informed decisions about your project.

CNC machining techniques allow product manufacturers to seamlessly switch between composite materials and designs. Hence, this approach is ideal for custom, one-off, and high-volume productions.

This organization is not BBB accredited. Power Actuated Tools in Waterford, MI. See BBB rating, reviews, complaints, & more.

Once you are logged in, a database of different tool library files will appear. You can use the search functionality at the top of the page to filter the results by brand name. For example, entering “Helical Solutions” into the search bar will show you only Helical Solutions tool libraries. You can also narrow your search to find Harvey Tool and Helical tool libraries by using the “tags” feature and choosing the brand you are looking for from the drop down menu.

Machining drilling and fastening composites guidepdf download

All that said the last time I had a custom router bit made it was around $350 in 2019 (1/2 shaft, 2.5 cutting height, custom angle bevel for ...

“We’re excited about our partnership with Harvey Tool and Helical Solutions and the performance their cutting tools bring to the market. Working together to make their digital tool libraries available to the Mastercam customer base has been a great collaboration between the two companies.”

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

This integration improves the chemical and physical properties, including durability, resistance to environmental factors, low thermal expansion, and thermal conductivity. Hence, composites are important in various manufacturing processes, especially CNC machining.

To learn more about Machining Advisor Pro and get started today, visit www.machiningadvisorpro.com. If you have any questions about MAP, please reach out to us at [email protected]

Once you have downloaded your tool library, you will need to import the tool libraries into Mastercam software by heading to the “Machine” tab, selecting “Mill”, and navigating to the “Toolpath” tab to access the Mastercam Tool Manager.

The high precision of the CNC process helps businesses reduce the amount of composite materials wasted. This efficiency is critical when machining expensive composites because it offers cost-saving benefits and reduced environmental impacts.

Composites are robust engineering materials formed by combining two unique materials, primarily producing a synthetic product with superior properties to its constituents. The unique composition of these materials is essential since one material forms the matrix while the other is the reinforcement.

CNC composite machining creates significant harmful dust and particles, creating a cleanup hassle and major safety and health concerns. Carbon fiber dust can produce fine particulates that can be inhaled and pose serious health risks. Similarly, these composite dust particles can damage the CNC machinery, resulting in frequent downtime and maintenance.

One way to find a tool is to search for a tool by tool number, or EDP number. For example, if you are looking for Helical Tool EDP 00015, you can find the EDP in the “Tool Name” field within the library.

Machining drilling and fastening composites guidepdf

Once you have downloaded and imported your tool libraries, selecting a specific tool or group of tools can be done in several ways.

To access speeds and feeds information for your Helical Solutions end mills, we recommend using our Machining Advisor Pro application. Machining Advisor Pro (MAP) generates specialized machining parameters by pairing the unique geometries of your Helical Solutions end mill with your exact tool path, material, and machine setup. MAP is available free of charge as a web-based desktop app, or as a downloadable application on the App Store for iOS and Google Play.

The best-rated product in Drill Bit Combination Sets is the Maxfit 1/4 in. Black and Gold Impact Ready Metal Drill and Steel Screwdriving Bit Set (120-Piece).

The interface is a critical composite constituent and a region where the reinforcement and matrix interact. It is a boundary layer essential to the composite material’s structural integrity and performance. The effectiveness of the interface is paramount for the composite’s mechanical properties, including stiffness, fracture resistance, and strength, since its primary responsibility is transferring load between the matrix and the reinforcement. Interfaces in composite materials include:

To ensure the best possible machining results, we have decided not to prepopulate speeds and feeds information into our tool libraries. Instead, we encourage machinists to access the speeds and feeds resources that we offer to dial accurate running parameters based on their material, application, and machine capabilities.

The matrix is a fundamental composite constituent that connects reinforcement materials firmly to shape and protect them from environmental factors. Matrices are of various types, each chosen depending on the composite material’s end use. These types include:

These materials add mechanical strength and rigidity to composites. Unlike matrix, reinforcements are usually stronger and stiffer. Hence, they enhance the overall properties of the composite material. There are different types of reinforcements, including:

I want to take a 1.0" ball nose end mill and make a bowl shape: For example, 4.5" diameter and 1.0 deep. I used to know the arithmetic formul.

The latest library files include new tooling from the Harvey Tool and Helical 2024 catalogs and the Valor Holemaking 2023 catalog. Simply download the latest version of the tool library using the links below to update your software.

0086-813-8127573

0086-813-8127573