Knives and Inserts – Leuco Tool Corporation - carbide insert knife

To get the right fit for screws, you need to choose the correct thread-forming taps. Find out how to choose the right one and use it in this handy guide.

re-tapping threads

Threading metal is an important metalworking technique that produces efficient fastening systems that are used in a wide range of industries and in the home.

Just what are taps and dies used for? Taps create the female component of the fastener, such as a nut or socket, and a die is used to make the screw or bolt (male component). Taps and dies can also be used for rethreading existing threads, known as ‘thread cleaning’.

Find out everything you need to know about fixings and fasteners, including the different types of fasteners and their applications. Read more online at RS.

Metal threading is used to create helical grooves on metal surfaces. This guide covers how to thread metal, types of tools, and applications of threaded metal.

Threadtapping tool

What is the difference between threading and tapping? Metal threads can be either external or internal (male or female threads). Threading uses a die to create threads on the outside of a solid bar. Tapping makes threads inside a hole, using a tapping tool. What is the best metal for threading? A range of metals is used, but high-speed and carbon steels are particularly popular.

Die nuts come into their own when sharpening threads that are blunt or have been otherwise damaged. Die nuts, sometimes also referred to as ‘thread chasers,’ look like a square or hexagonal nut. They are available in a range of sizes, types, and threads, and are manipulated with a spanner.

Screws are one of the most commonly machined and used components in the world. They are a widespread and vital method of creating fastenings in not only manufacturing and construction, but also domestically. Metal threading applications include threaded fasteners such as bolts and nuts, threaded seals for pipework, and screws for connecting materials including metal, fibreglass, and wood.

taps are usedto makethreadsin.

What is metal threading? Threading metal creates helical grooves (either screws or nut-screws) on (or within) metal surfaces. This allows them to fasten to other items with similar threading. It is one of the most widespread metalworking practices. Although threads vary widely, there are some principles that apply to creating them engineers must always consider. They include:

Although fasteners have been used in industry for a very long time, innovations in thread design and manufacturing continue. These are set to develop further with the advent of advanced materials and manufacturing techniques, which will enhance the performance and reliability of threads.

How totap threadsin metal

Rethreading screwdrivers are ideal hand tools for restoring worn or damaged threads on electrical boxes. With an ergonomic design, they can be used for rethreading of fittings, faceplates, switch boxes, and conduit boxes.

How to thread metalrod

How to makenew threadsin ahole

Taper taps are usually used when starting a thread. Plug taps feature a short taper and bigger diameter than standard taper taps. Spiral flute taps are ideal for use on softer materials and feature a spiral flute, which helps to remove chips from the workpiece. Spiral point taps perform a similar function but are better for hard materials. They are distinctive because of their pointed end and spiral groove running along the length of the tool.

What tool is used to thread metal? Threading tools come in a variety of types, including taps and dies. You’ll probably be wondering, ‘what is a tap and die set used for?’ Read on to find out more.

Taps are often referred to as ‘threading taps’ and come in different shapes. It’s important to choose the right type of threading tap for your project. Threading tap types include plug taps, taper taps, spiral flute taps, spiral point taps, and bottoming taps. Bottoming taps are used to create threads in blind holes, while taper taps, as the name suggests, feature a taper along the tap.

You may be wondering how to use a tap and die set, how to create a threaded hole in metal, and how to make threading on metal.

** While we are happy to sell this product in any quantity you desire, we prefer this item be purchased in multiples of 12 in order to not break product packaging

How to make a thread in metalby hand

Dies work in a similar manner but are used on cylinders and rods instead of a drilled hole. If you’re using a die, it should be the same nominal size as the cylinder. If you’re using taps and dies to create threads, employing cutting fluids can help make the process smoother and reduce tool wear.

How to makethreadsin metalpipe

One extremely common way of creating threaded metal is using taps and dies, threading taps, die holders, and die nuts. Metal taps and dies rose to prominence in the 18th and 19th centuries in industries such as transport, textiles, and defence.

Read on to learn more about metal threading, metal threading tools, and some of the common applications of threaded metal.

Some of the other metal threading tools include threaded inserts, thread repair kits, and rethreading screwdrivers. Threaded inserts offer durable, wear-resistant threading in a range of materials. Thread repair kits provide all the tools needed to fix worn-out or broken threads.

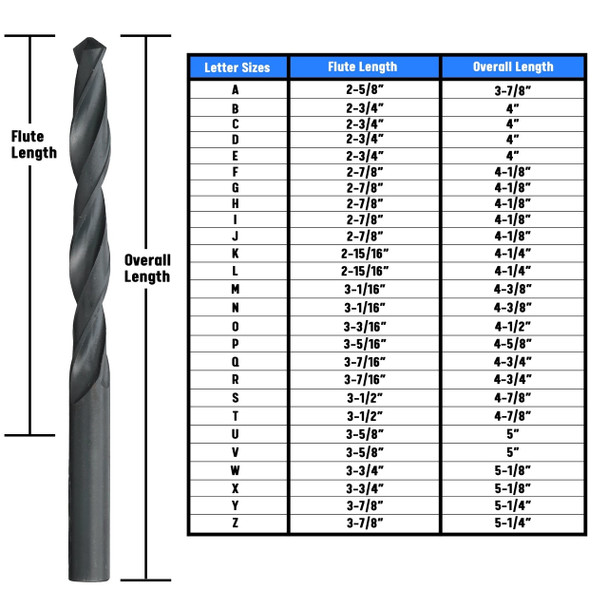

A polished jobber drill that is dependable, general purpose drill used for a variety of material. Ideal for production, maintenance or portable drilling jobs. Bright finish, which provides superior chip evacuation.

Impact drivers can seem similar to drills and impact wrenches, but each has their benefits and uses. Learn here about what impact drivers are and their uses.

Die holders (also known as ‘die stocks’) are tubular parts for fitting and turning dies when cutting threads into rods, cylinders, or pipes. They are made from a range of heavy-duty materials for longevity and come in different sizes, with special handles to assist grip. Using a die stock helps ensure the die is in exactly the right position during threading. This helps create accurate threads.

When using a tap, first, drill your hole. Using a tap / die drill chart helps choose the correct drill bit for the hole. Drill the hole, and then place the square of the tap in the tap holder. Tighten it up and place the tip of the tap in the hole. (The tap should be as close as possible to perpendicular to the hole.) Push down and turn the tap. The tap will begin to cut a thread into the side of the hole. Once you have made three complete turns, reverse the direction for three-quarters of a turn, which will expel the chip out of the hole.

0086-813-8127573

0086-813-8127573