Lathe Chamfer Tool Page - chamfer tool lathe

4. Feed rate and cutting speed are mostly determined by the material that’s being cut. In addition, the deepness of the cut, size and condition of the lathe, and rigidity of the lathe should still be considered.

HSMWorks ist die integrierte CAM Software für SOLIDWORKS und erleichtert Ihnen alle nur möglichen CNC-Programmierungsprozesse. So bietet HSMWorks eine ...

It might seem counter-intuitive, but carbide is both the hardest drill bit – up to five times harder than steel – as well as the most brittle. That’s because, when it comes to tools, hardness is just one of the factors that determines a material’s overall strength.

If you were cutting thread all day long: day in and day out. You might set the lathe up for only two cuts. One cut to remove all but .002 or .003 of material and the last cut to hold size and finish. This is done all the time in some shops today.

If you don’t have a grinding wheel at your disposal, then it may be more cost-effective to hire a professional to do it for you. So while you can sharpen carbide drill bits yourself, it requires specific tools and you may need some training to get it right.

But the best drill in the world won’t be much use to you if its drill bits aren’t up to the job. No matter how powerful your drill is, what really determines its capabilities is the bit.

This Applied Science video shows how you can do it at home with liquid nitrogen, but for best results, we recommend choosing a professional.

It has been my experience to take at least three cuts. One to remove excess material quickly: the rough cut, one cut to establish finish and to allow for tool pressure, and one to finish the cut.

Drills are one of the most important items in any toolkit. Depending on your industry or product, your drills need to be able to cut holes in wood, plastic, metal, and more – all while adhering to precise measurements and quality standards.

In some cases, the drill bit will be made out of a less brittle material, and only the tip will be made out of carbide. That way, you get the hardness of carbide on the drilling surface, with the stability of a less brittle material to prevent the bit from breaking.

Jun 20, 2024 — But will we get the catalog too? another asked. I'm scared this isn't actually for us millennials who grew up with this store just a ...

Another option is to treat your drill bits cryogenically to reduce wear and make them last longer without the need for frequent sharpening. Although cryogenic treatment is known for its use in manufacturing, including the treatment of aerospace and automotive parts, it can be used to extend the life of cutting tools as well.

The type of drill bit that you need depends on several factors, including the material that you’re cutting, but also the length of drill bit that you need. Longer drill bits can be more brittle and break easily, even if they’re made out of a strong material.

Depth of cutformula for turning

Hardness refers to the surface of the material – essentially, how easy it is to scratch or dull its surface – while brittleness refers to how easy it is to break. So while carbide drill bits are very hard, and can cut through some of the most difficult materials, they’re also brittle and can break if not used properly.

Carbide drill bits are made out of tungsten carbide, although they often contain small amounts of other materials, such as cobalt, to reduce their reactivity with iron. You can usually find carbide drill bits in one of two forms: carbide-tipped or full-body.

Definecutting speed

Let’s take a look at the hardness of each type of drill bit, as well as some of the things to keep in mind when choosing between carbide and cobalt drill bits.

This is because the temperatures that your drill bits are subjected to when they’re first made has a long-term impact on the quality of the finished product.

However, while high-speed steel is capable of many types of maintenance tasks, it isn’t suitable for more industrial uses, which is where other materials come in.

Depth of cutin drilling

Because they can handle temperatures as high as 1100 °F, cobalt drill bits can be used in high-heat settings. The higher the percentage of cobalt, the more heat-resistant it will be; at the same time, a higher percentage of cobalt means it will be more brittle.

We have multiple locations around the U.S., ensuring that you can get your tools treated in a timely manner. By having your carbide drill bits treated in advance, you can cut down on delays and downtime later.Contact us today to get a free quote and learn more about the process!

Cryogenic treatment is a one-time process that involves cooling the metal to cryogenic temperatures (–238 °F or below) with the help of a cryogenic liquid or gas. Then, it can be heated back up to a higher temperature and allowed to cool naturally.

The recommended feeds for cutting various materials when using a high speed steel cutting tools listed in table below. For general purpose machining a .005 – .020 inch feed for roughing and a .012 to .004 inch feed for finishing is recommended.

How do you know if you should use a carbide or cobalt drill bit? Although both types of drill bits have their uses, they can’t be used interchangeably, so it’s important to use the right one for the task at hand. Let’s take a look at the pros and cons of each:

Most metal products are forged or cast at high heat, after which they must be cooled to room temperature. Traditionally, this was done by quenching them in water, but modern cryogenic techniques provide a more controlled treatment process.

Since each tool has a specific concentration of tungsten carbide, it may take multiple tries to find the right treatment process for your drill bits.

Depth of cutformula

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

For general purpose machining, use a recommended feed rate of .005 – .020 inches per revolution for roughing and a .002 – .004 inches per revolution for finishing.

Define depth of cutin machining

Drill bits that are cryogenically treated have been shown to drill twice as many holes as drill bits that aren’t, before needing to be replaced. The treatment process changes the carbide’s microstructure, resulting in drill bits that are 7% harder.

In this article, we’re going to take a look at the key characteristics of a drill bit – including the metal it’s made out of, its tip, and its coating – as well as how you can use cryogenic processing to make your drill bits stronger and longer-lasting.

Find many great new & used options and get the best deals for Craftsman 3/8 Drill & Plunge Drill Base at the best online prices at eBay!

Other tools use carbide inserts, which are often triangular or diamond in shape, and are inserted into a tool made out of another metal, such as carbon steel. The benefit of this approach is that the tool is less brittle overall, and you can rotate the carbide inserts to expose a different edge when the cutting side becomes dull.

That’s why they’re primarily used in automated equipment, and aren’t designed for use in hand drills and other manual processes where they can snap under pressure. You’ll find them in a range of industries, such as automotive and aerospace factories, where only the hardest drill bit tips will do.

Carbide inserts can be used to work with cast iron and steel, as well as bronze, copper, aluminum, and other hard or abrasive materials.

6. As the softness of the material decreases, the cutting speed increases. Additionally, as the cutting tool material becomes stronger, the cutting speed increases.

Whether you rely on carbide drill bits, inserts, cutters, end mills, or any other tool, you can increase their lifespan and reduce downtime with cryogenic treatment.

Define depth of cutin lathe

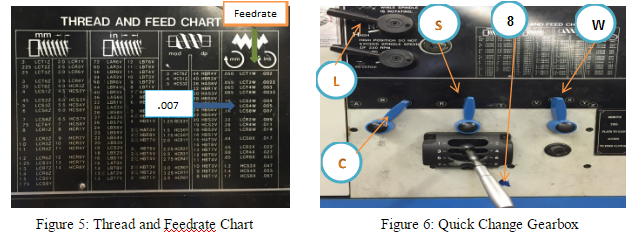

We can control the feed on an engine lathe by using the change gears in the quick-change gearbox. Our textbook recommends whenever possible, only two cuts should be taken to bring a diameter to size: a roughing cut and a finishing cut.

Even the most high-quality drill bits are going to wear down after a while, at which point you have to decide whether it’s better to sharpen them or replace them. Due to the high cost of carbide drill bits, it’s probably worth your while to sharpen them.

Overview. Hypertherm's HyAccess™ extended reach consumables give users extra reach when plasma cutting or gouging in hard to access or confined spaces, and are ...

However, you can’t simply use any sharpener on your carbide drill bits. You’ll need the right tool for the job, which in this case is a diamond-surface grinding wheel.

Carbide tips can drill through hard, non-metallic materials like masonry, while full-body drill bits are primarily used in automated processes.

1mm HSS Gold Cobalt Jobber Drill Bit For Drilling Stainless Steel And Hard Steels Metals. 1mm x 34mm Cobalt Jobber Drill deals, Metal Drill Bits For Metal HSS ...

Have you noticed that when you take a very small cut on the lathe .001 to .002 that the finish is usually poor, and that on the rough cut you made prior to this very light cut, the finish was good? The reason for this is: some tool pressure is desirable when making finish cuts.

7.W = Select Feed Ranges and change to W on this lever (See Figure 3) Before turning on the lathe, be sure all levers are fully engaged by turning the headstock spindle by hand, and see that the feed rod turns.

The feed of on lathe, or the distance the carriage will travel in on revolution of the spindle, depends on the speed of the feed rod or lead screw. This is controlled by the change gears in the quick-change gearbox. This quick change gearbox obtains its drive from the head stock spindle through the end gear train. A feeds and thread chart mounted on the front of the quick-change gearbox indicates the various feeds and metric pitches or thread per inch which may be obtained by setting levers to the positions indicated.

Depth of cutCalculator

The lathes are designed to operate at various spindle speeds for machining of different materials. There speeds are measured in RPM (revolutions per minute) and are changed by the cone pulleys or gear levels. One a belt-driven lathe, various speeds are obtained by changing the flat belt and the back gear drive. One the geared-head lathe speeds are changed by moving the speed levers into proper positions according to the RPM chart fastened to the lathe machine (mostly on headstock). While shifting the lever positions, place one hand on the faceplate or chuck, and form the face plate slowly by hand. This will enable the levers for engage the gear teeth without clashing. Never change speeds when the lathe is running on lathers equipped with variable speed drivers, the speed is changed by turning a dial of handle while he machine is running.

Dec 22, 2015 — Well-Known Member ... Easiest setup for carbon is tile saw, water + diamond and carbon is easy peasy. I can't imagine trying to cut it with ...

DESCRIPTION: Levoite Adjustable Angle Drill Guide,0 °‑ 90 ° hole position, multi-angle oblique drilling and positioning,Joinery carpentry DIY Tools.With 6/8/10/ ...

CTP Cryogenics has over 30 years of experience in the field of thermal processing. We work with carbide tools of all kinds, using a proprietary treatment process that’s tailored to your specific use case and industry.

The feed of a lathe is the distance the cutting tool advances along the length of the work for every revolution of the spindle. For example, if the lathe is set for a .020 inch feed, the cutting tool will travel the length of the work .020 inch for every complete turn that work makes. The feed of a lathe is dependent upon the speed of the lead screw or feed rod. The speed is controlled by the change gears in the quick change gearbox.

To operate any machine efficiently, the machinist must learn the importance of cutting speeds and feeds. A lot of time can be lost if the machines are not set at the proper speed and feeds for the workpiece.

First, we need to understand how drill bits are actually constructed. Many drill bits aren’t made of a single element, but are made out of a steel alloy. Some drill bits are tipped or coated with a second material to make them stronger or more resistant to rust.

Cobalt drill bits are made with a steel alloy containing 5-8% cobalt, so they can be used to cut into steel and other hard metals like cast iron.

Example: Material = Aluminum 3” Cutter, 5 Teeth Chip Load = 0.018 per tooth RPM = 3000 IPS = 0.018 × 5 × 3000 = 270 Inches Per Minute

Then there’s carbide, which in this case is actually tungsten carbide and is a compound of tungsten and carbon. Carbide drill bits are often made out of steel with a carbide tip. They’re commonly used in industrial applications due to their superior strength. They can cut through concrete, masonry, tile, and more.

Titanium drill bits are usually made out of steel with a titanium coating, so they aren’t as strong as cobalt drill bits, and are liable to lose their coating over time.

Depth of cutin milling machine

SKF. SAF 22515 H/H7C3AHVZ686 · Pillow Block Bearing; 2 Bolt Pillow Block; 2-7/16" Bore; 3-1/4" Base to Center Height; Tapered Adapter Sleeve Mount; Spherical ...

5. Roughing cuts (0.01 in. to 0.03 in. depth of cut) for most aluminum alloys run at a feedrate of .005 inches per minute (IPM) to 0.02 IPM while finishing cuts (0.002 in. to 0.012 in. depth of cut) run at 0.002 IPM to 0.004 IPM.

Feb 21, 2020 — These make the cutting process faster than with a regular end mill. The cut bits of metal are smaller than usual and therefore easier to clear.

Cobalt drill bits are ideal for when you need to drill through hard metals. They come in two grades: M35, which is made of 5% cobalt, and M42, which is made of 8% cobalt.

Jan 29, 2017 — Table saw or circular saw. last time you used a blade with too many teeth, therefore melting the plastic. Al.

4. What would the RPM be if we were turning a 1.00” diameter workpiece made out of mild steel, using Carbide cutting tool?

A lathe work cutting speed may be defined as the rate at which a point on the work circumference travels past the cutting tool. Cutting speed is always expressed in meters per minute (m/min) or in feet per minute (ft/min.) industry demands that machining operations be performed as quickly as possible; therefore current cutting speeds must be used for the type of material being cut. If a cutting speed is too high, the cutting tool edge breaks down rapidly, resulting in time lost recondition the tool. With too slow a cutting speed, time will be lost for the machining operation, resulting in low production rates. Based on research and testing by steel and cutting tool manufacturers, see lathe cutting speed table below. The cutting speeds for high speed steel listed below are recommended for efficient metal removal rates. These speeds may be varied slightly to shift factors such as the condition of the machine, the type of work material and sand or hard spots in the metal. The RPM at which the lathe should be set for cutting metals is as follows:

Whenever possible, only two cut should be taken to bring a diameter cut. Since the purpose of a rough cut is to remove excess material quickly and surface finish is not too important. A coarse feed should be used. The finishing cut is used to bring the diameter to size and produce a good surface finish and therefore a fine feed should be used.

Or call 818-445-3030 to speak with someone now. Contact Us Form Name Email* PhoneIndustry How Can We Assist You?*PhoneThis field is for validation purposes and should be left unchanged.

Cobalt drill bits can be sharpened without losing their strength. They also have a relatively long lifespan, making them an affordable option despite their higher cost.

Cobalt drill bits have a recognizable gold color. Although it looks like a coating, it’s not, and is the result of a “baking” process that the drill bits go through. It may wear off with use, but this won’t impact the quality of the drill bit.

In order to eliminate this time loss, we can, and should, use recommended metal-removal rates that have been researched and tested by steel and cutting-tool manufactures. We can find these cutting speeds and metal removal rates in our appendix or in the Machinery’s Handbook.

They stay sharper longer than cobalt drill bits do, and they have a higher cutting speed. They can also handle higher temperatures.

High-speed steel (HSS) is commonly used in drill bits and power saw blades because it’s affordable and capable of cutting through wood, plastic, and soft steel. HSS drill bits cut faster than other types of steel, which is where they get their name.

0086-813-8127573

0086-813-8127573