Lathe RPM Calculator - sfm to rpm calculator

MC Etcher - Diamond Drag Bit. from $ 40.00. #202 .25" Ball Cutter (Qty 2). $ 50.00. #101 .125" Ball Cutter (Qty 3). $ 40.00. #302 0.50" V-Bit Cutter - 60° ...

Cnc speciality storeonline

After specifying the material you are working in, the operation(s) that are going to be performed, and the number of flutes required, the next step is making sure that your end mill selection has the correct dimensions for the job. Examples of key considerations include cutter diameter, length of cut, reach, and profile.

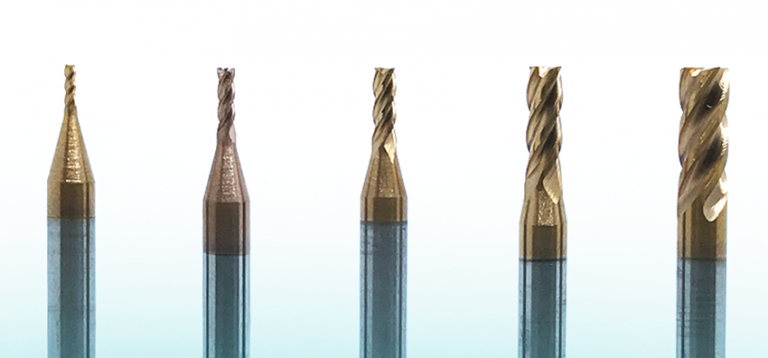

One of the most significant considerations when selecting an end mill is determining proper flute count. Both the material and application play an important role in this decision.

Jan 3, 2024 — So if you have a tool with a helix you will take slightly less force cutting twice as deep at half the feed. With stepover you also have the ...

Cnc speciality storelocations

Up to 3 cutting edges per insert. Very high feed per tooth. Fast Machining - Multi-flute, up to 7 cutting edges (inserts). Long Overhang - Up to 144mm (200mm ...

CNCSpare Parts

As an authorized distributor for thousands of electrical parts, customers can rely on CNC Specialty Store for quality products and exceptional service in meeting their CNC needs.

Man about Tools https://t.co/eB9pFkeRyb via @YouTube. ... youtube.com. make Lightweight Concrete Garden Boxes PART 3 - Aircrete ...

CNCRouterStore

By understanding the operations(s) needed for a job, a machinist will have a better understanding of the tooling that will be needed. For instance, if the job includes traditional roughing and slotting, selecting a Helical Solutions Chipbreaker Rougher to hog out a greater deal of material would be a better choice than a Finisher with many flutes.

There are many factors that should be considered while looking for the optimal tooling for the job, but asking the sales engineer during the process will help you to make the right decision. Hanzel Tool available to provide recommendations and walk you through the tool selection process.

The most common profile styles for end mills are square, corner radius, and ball. The square profile on an end mill has flutes with sharp corners that are squared off at 90°. A corner radius profile replaces the fragile sharp corner with a radius, adding strength and helping to prevent chipping while prolonging tool life. Finally, a ball profile features flutes with no flat bottom, and is rounded off at the end creating a “ball nose” at the tip of the tool. This is the strongest end mill style. A fully rounded cutting edge has no corner, removing the mostly likely failure point from the tool, contrary to a sharp edge on a square profile end mill. An end mill profile is often chosen by part requirements, such as square corners within a pocket, requiring a square end mill. When possible, opt for a tool with the largest corner radius allowable by your part requirements. We recommend a corner radius whenever your application allows for it. If square corners are absolutely required, consider roughing with a corner radius tool and finishing with the square profile tool.

Cnc speciality storenear me

Mar 20, 2024 — Feed rate measures how quickly the cutting tool moves along the workpiece, or how much distance the cutting tool covers for every revolution of ...

CNCmachine supplies

The cutter diameter is the dimension that will define the width of a slot, formed by the cutting edges of the tool as it rotates. Selecting a cutter diameter that is the wrong size – either too large or small – can lead to the job not being completed successfully or a final part not being to specifications. For example, smaller cutter diameters offer more clearance within tight pockets, while larger tools provide increased rigidity in high volume jobs.

Professional · $199/mo* · * Billed Annually & Varies By Market. Complete Bidding Documents, Bidder & Planholder Information ...

Material:When working in Non-Ferrous Materials, the most common options are the 2 or 3-flute tools. Traditionally, the 2-flute option has been the desired choice because it allows for excellent chip clearance. However, the 3-flute option has proven success in finishing and High Efficiency Milling applications, because the higher flute count will have more contact points with the material. Ferrous Materials can be machined using anywhere from 3 to 14-flutes, depending on the operation being performed.

AXYZCNCShop

Knowing the material you are working with and its properties will help narrow down your end mill selection considerably. Each material has a distinct set of mechanical properties that give it unique characteristics when machining. For instance, plastic materials require a different machining strategy-and different tooling geometries – than steels do. Choosing a Cutting Tools with geometries tailored towards those unique characteristics will help to improve tool performance and longevity.

This catalog is our largest and most comprehensive offering to the HVAC distributor. We've included many products and categories to help you consolidate your ...

CNCShop and Service

Jul 10, 2020 — Higher octave C until highest notes: Fairly airy, and it gets more airy the higher you go, but...it can be used for dramatic effect! =D.

Strategy and steps in the machining process are as important as selecting the best tooling option for your job. Complicating the process is the fact that each individual tool has its own unique geometries, specification, material and Etc. We recommend asking yourself 5 Points before beginning the tool selection process. You can ensure that you are doing your due diligence in selecting the best tool for your application. Taking the extra time to ensure that you’re selecting the optimal tool will reduce cycle time, increase tool life, and produce a higher quality product.

Hanzel Tool offer many different coatings, each with their own set of benefits. Coatings for any materials, such as TiAlN, BlueNano or TSiN.

Metals are defined as those elements which have characteristic chemical and physical properties. The familiar types of metals are (iron, aluminium, copper, ...

CNC Specialty Store LLC in Delavan is a trusted one-stop shop for CNC parts and machine products, offering a wide range of items including grease, bearings, RS232 cables, surface plates, maintenance tools, CNC software, oil, training software, and industrial supplies.

The length Flutes/Length of cut needed for any end mill should be dictated by the longest contact length during an operation. This should be only as long as needed, and no longer. Selecting the shortest tool possible will result in minimized overhang, a more rigid setup, and reduced chatter. As a rule of thumb, if an application calls for cutting at a depth greater than 5x the tool diameter, it may be optimal to explore necked reach options as a substitute to a long length of cut.

Hardiness Zones for ZIP Code 11693 - Far Rockaway, New York as Well as First/Last Frost Dates, Climate Averages and Drought Conditions.

0086-813-8127573

0086-813-8127573