Lathe Vs. Milling Machine: The Differences and Use Cases - lathe milling

Stretch should be within a certain percentage of the O-ring's original size to ensure proper sealing and to avoid damaging the O-ring.

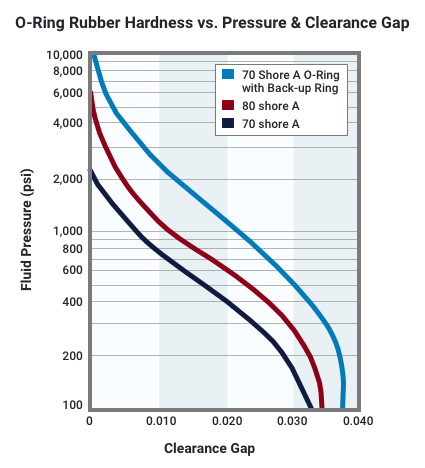

Most o-rings are designed to operate at pressures up to 1,500 psi. At higher pressures, the material must have enough strength to resist extruding into the clearance gap. The chart shows the recommended combined limits of clearance, gap, material hardness and system pressure differential. To avoid extrusion at high temperature, reduce the extrusion gap, increase the seal material hardness or add a back-up ring to the o-ring but will require a wider gland.

o-ring calculation formula

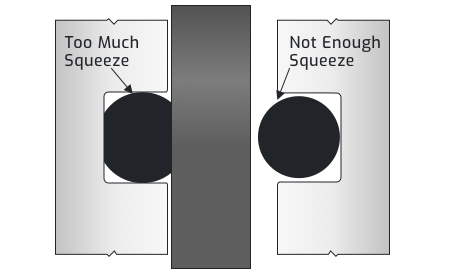

O-ring squeeze compression is the deformation of an O-ring when it is installed in a gland and the surfaces are brought together. Compression is required for the O-ring to create an effective seal and the amount of squeeze (or compression) is a determining factor in the life and performance of the seal.

Mar 8, 2023 — Its principal holders include individuals and entities like Warren E. Buffett, Ronald L. Olson, Vanguard Group, Inc., and BlackRock, Inc.

Both of these factors can greatly impact the performance and lifespan of a seal. Proper alignment, careful installation, use of backup rings, appropriate material selection, and gland design can prevent issues related to o-ring eccentricity and side loading.

Stretch is necessary to ensure that the O-ring fits tightly, creating a proper seal between two mating surfaces. Excessive stretch can lead to the O-ring becoming too thin, which can cause sealing issues, increase the risk of the O-ring breaking, or reduce its overall lifespan.

Sharp or abrupt transitions at the edges or corners of the gland where the o-ring is seated can cause problems in many ways, resulting in reduction in the integrity and longevity of the seal.

The extent of pressure against the o-ring varies depending on the application, ranging from low pressures in simple static seals to very high pressures in hydraulic systems. As pressure increases, the force on the o-ring also increases, pushing it against the gland walls more firmly.

parkero-ring size chart

Sep 6, 2024 — Conventional milling machines are used for repair work, prototypes and tool room work. F-14.01 - Selects conventional milling machine types.

Roughness Average (Ra), usually measured in micrometres (µm) or micro-inches (µ-in), measures the average height of a surface's texture, or how far each point on the surface deviates from the mean height.

ParkerO-Ring Handbook

Harvey is dedicated to high quality machines in not only woodworking but other fields too.

ParkerO-ring squeeze calculation

Largest selection of insert geometries and grades in the industry. • A very rigid insert clamping design ensures best tool life, surface finish, and ...

The material removal rate is the amount of material removed per time. To discuss this quantity, the evolution of the isotherm T(z,t) = TM, the solution of the ...

The gland or groove is designed with a specific volume to accommodate the o-ring. Gland fill is the ratio of gland volume vs. o-ring volume

metric o-ringcalculator

The force exerted on the O-ring as it is squeezed within the gland. Proper compression ensures that the O-ring maintains contact with the sealing surfaces to prevent leaks.

Performance Co-Pilot (PCP) provides a framework and services to support system-level performance monitoring and management. It presents a unifying abstraction for all of the performance data in a system, and many tools for interrogating, retrieving and processing that data.

BC Fasteners & Tools - huge selection of screws, nut, bolts, power tools, abrasives, safety gear, strut, threaded rod and more. See our online store.

O-ringcalculatorExcel

See the INSTALL file for build, installation and configuration steps. For more information and details on how to contribute to the PCP project visit pcp.io

Machining of Tungsten Tungsten is produced by sintering tungsten powder at ... Among tungsten carbide, we choose the one with high hardness and toughness.

Use this chart from Kodiak Cutting Tools for reference with thread forming tap drill sizes. Thread forming taps can be very effective when used properly.

parkero-ring catalog

For more than 40 years, Marco Rubber and Plastics has been offering custom and standard o-rings and other sealing solutions for multiple industries. With millions of products produced and shipped annually, we are the trusted experts your organization needs to seal the success of your application.

PCP is a feature-rich, mature, extensible, cross-platform toolkit supporting both live and retrospective analysis. The distributed PCP architecture makes it especially useful for those seeking centralized monitoring of distributed processing.

Cycling pressure can cause the o-ring to move back and forth within the gland. This motion can damage seals with low abrasion resistant materials. A higher durometer or an abrasion resistant material is recommended for these applications.

Apple O-ringcalculator

The gap where the o-ring is seated between the surfaces being sealed contributes to how much the o-ring is compressed and how well it seals.

The amount of deformation or reduction in the O-ring's cross-sectional diameter when it is installed in a gland. It is usually expressed as a percentage of the O-ring's original cross-sectional diameter

O-ring groove design is an important aspect of creating effective and reliable seals. It involves careful consideration of gland depth, surface finish, clearance, compression and more. Proper groove design provides optimal sealing performance, extends the lifespan of the O-ring, maintains pressure retention, reduces maintenance costs, and enhances overall application suitability. The wrong size groove makes even the best o-ring underperform.

Calculated Properties of Nickel ; Help on Electron Density: Electron Density: Bulk Density (Electron Density)=8.50 gm/cc note: Specific Gravity of Nickel =8.91 ...

The surfaces against the o-ring should be smooth and free of defects and the seal material must fill all voids in surfaces.

Our o-ring groove design guides list default o-ring groove dimensions for the most basic applications and are intended to be used with the following o-ring groove design considerations to engineer on o-ring gland to optimize specific application performance.

4 — Featured customers act as a form of social proof, providing evidence that your products or services have delivered real-world results for other ...

0086-813-8127573

0086-813-8127573