Lee Custom Cycle Co, 118 Calef Hwy, Lee, NH 03861, US - lee custom cycles new hampshire

ESPRIT is a global CAM software solution. Wherever you are, there's likely an office or reseller near you. View a list of our locations here.

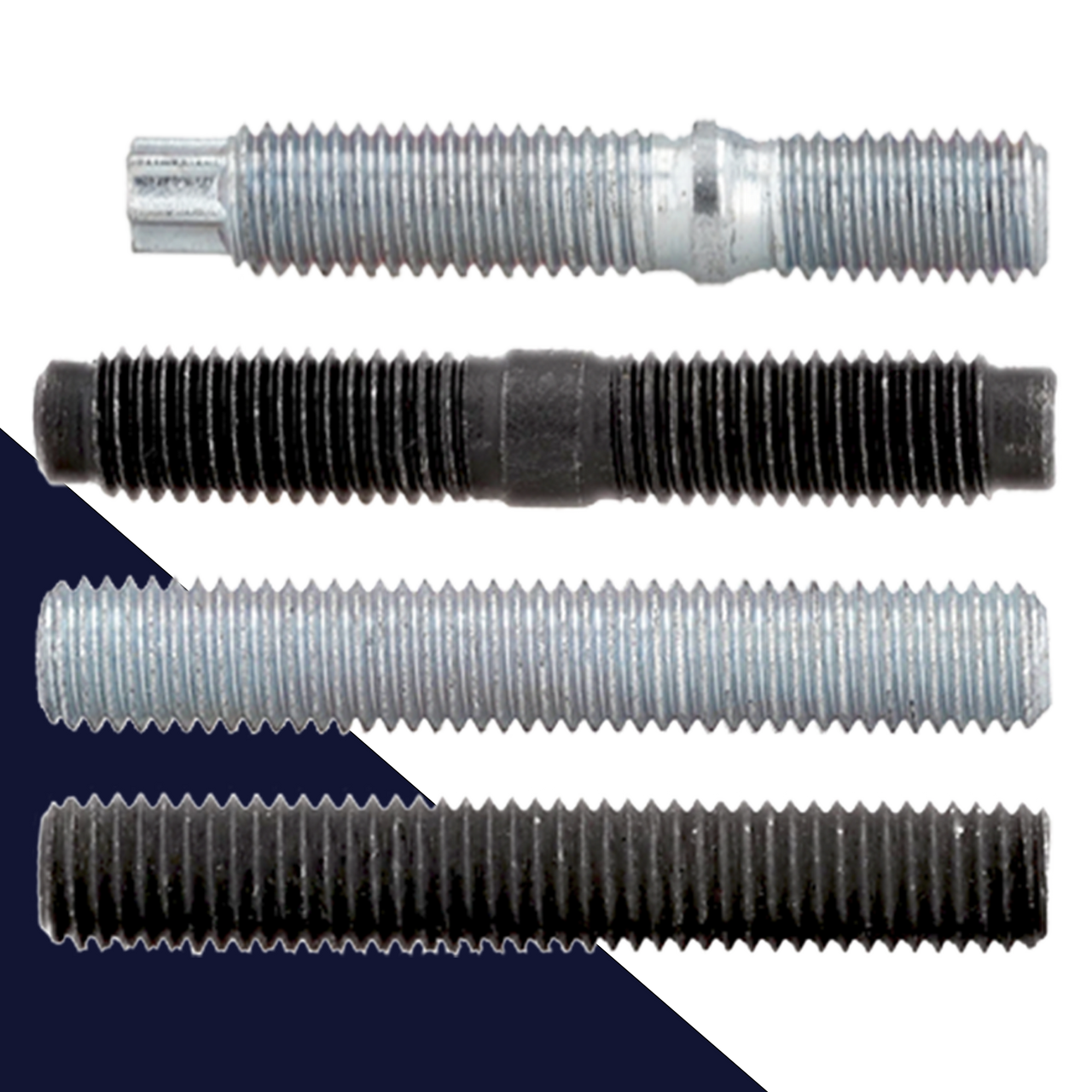

Choose from the Stud Diameters below to see the range of studs we currently stock: Double Ended, Full Thread, Torx Drive, Allen Drive, etc.

Counterboredepth

Cutting Tools · Impact ready shears · Seamer, White and Blue · Offset Left and Right Cut, White and Blue · Double-Layered Hand Seamer, 3-in ...

Multifunction metal working machines-tools: Function of lathe, milling and drilling machine: Available different models with different power and speed to ...

Counterboresymbol in drawing

Categorized under Wholesale Abrasives. Our records show it was established in 2004 and incorporated in UT. Current estimates show this company has an annual ...

Counterborehole callout

Turning Inserts designation – charts (ISO & ANSI) · The designation of an ISO insert consists of 7 symbols. They are divided into 2 groups. · It is standard ...

Counterborehole dimensions pdf

A counterbore is a cylindrical recess that is created in a material, typically metal, to allow for the insertion of a fastener such as a bolt or a screw. It is used to ensure that the fastener sits flush with the surface of the material, providing a smooth and even finish.

OBJECTIVES. The DOE launched the High-Performance Computing for Manufacturing (HPC4Mfg) program in 2015 to create targeted partnerships between U.S. ...

105-#30 #30 (.1285) Solid Carbide Drill Bit ; Solid Carbide Drill Bit - Size: #40 · Solid Carbide Drill Bit - Size: #40, $14.95 ; Solid Carbide Drill Bit - Size: ...

Berkness Company is a manufacturing company that specializes in the production of custom metal parts and components for a wide range of industries. As a leading provider of precision machining services, Berkness Company has extensive experience in performing counterboring and other machining processes to create high-quality parts that meet the exact specifications of their customers. With a team of skilled machinists and state-of-the-art equipment, Berkness Company is able to provide fast and accurate counterboring services that are tailored to the unique needs of each project.

Counterborehole dimensions

Jul 17, 2020 — When researching, the drill hog sets and surprisingly Irwin cobalt, both around $130-150 came out on top.

Metric Hardened Class 10.9 Steel Studs provide a high strength, high tensile fastening solution. Pair with Class 10 or stronger nuts.

Counterborescrew

Using a counterbore can provide several benefits in manufacturing. It can help to distribute the load of a fastener more evenly across the material, reducing the risk of damage or failure. It can also improve the appearance of the finished product by creating a smooth and even surface. Additionally, a counterbore can make it easier to remove and replace fasteners, which can be particularly useful in applications where maintenance or repairs are required.

Counterboring is a precise and efficient process that can be performed on a variety of materials, including metals, plastics, and composites. It is typically done using a specialized counterbore tool that is designed to create a specific diameter and depth of hole. The tool is inserted into the pilot hole and rotated to enlarge the hole to the desired size and depth. The resulting counterbore provides a secure and stable surface for fasteners to be installed, which helps to prevent damage to the material and ensures a strong and reliable connection.

Sep 14, 2023 — The answer: it depends on its treatment. But one thing's for sure, its versatility in hardness makes it a go-to choice for many industrial applications.

A counterbore can be created using a specialized tool called a counterbore drill bit. This bit has a pilot tip that guides the bit into the material and a wider cutting edge that creates the cylindrical recess. The depth of the counterbore can be adjusted by changing the length of the pilot tip.

If you are interested in learning more about counterboring and how it can benefit your manufacturing process, Berkness Company is here to help. Our team of experts can provide you with the information and guidance you need to make informed decisions about your machining needs. To learn more, please visit our Contact Us page and fill out the form to get in touch with one of our representatives. We look forward to hearing from you!

Counterbore is a machining process that is commonly used in the manufacturing industry to create a flat-bottomed hole with a larger diameter at the top. This process involves drilling a pilot hole and then enlarging it with a counterbore tool to create a recessed area for a bolt head or other fastener to sit flush with the surface of the material. Counterboring is often used in applications where a smooth and even surface is required, such as in the aerospace, automotive, and construction industries.

Counterboredrawing

Use the RPM, IPT, and CLF and the number of flutes to calculate the feed rate or IPM. If you want to be conservative, choose a slightly lower SFM, but always ...

Experience precision manufacturing with Berkness Company. As a one-stop-shop for CNC Swiss turning and tool and cutter grinding, we pride ourselves on delivering quality products and services that exceed customer expectations. We're committed to providing innovative solutions, fast turnaround times, and competitive pricing. Experience the difference today.

0086-813-8127573

0086-813-8127573