Logan's Sausage Company to open manufacturing plant in ... - logan manufacturing company

Exact Tool Company, Inc., 2123 Foster Avenue, Wheeling, IL 60090-6506847-632-1140, FAX 847-632-1148, email: info@exacttool.comSite Created and Maintained by Adams Internet Solutions Ltd.

Exactpipe cutter 170E

Stampings for the Lock Industry: Cams, Back-Plates, Washers, Spring Retaining Clips, & Keys of Brass, Steel & Zinc. ETCI Virtually Makes all Components for Locks.

ExactP1000

CoolCut specialty-length shaver blades feature a wide range of high-quality, single-use shaver blades for arthroscopic surgical procedures of the ankle, wrist, and elbow.

With these tough economic times we all have to run lean operations. Give Exact Tool a chance to quote and see if Exact Tool can reduce your costs. You will not be disappointed with Exact Tool's quality and service.

Exakt saw

ExactPipe Cutter 220E

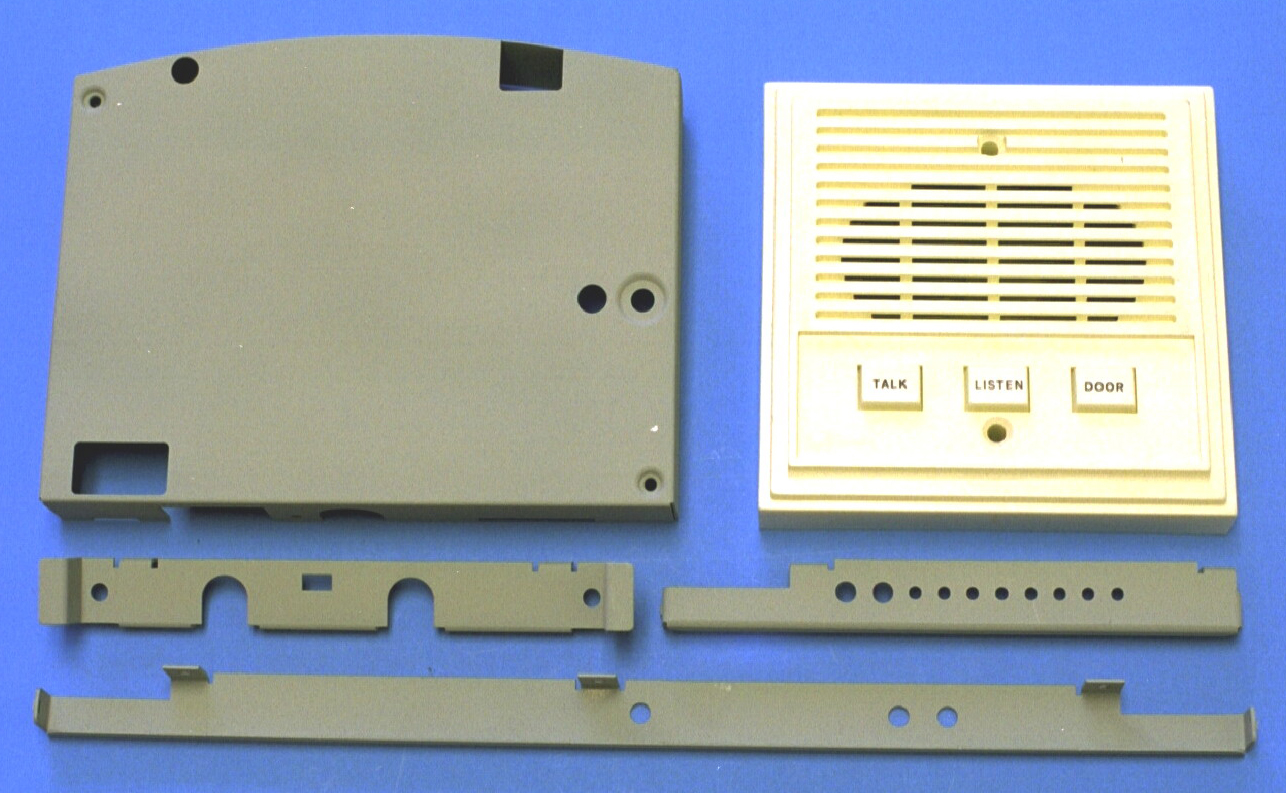

Electrical Component Enclosure, a Polymer Speaker Faceplate w/ Talk, Listen, Door Buttons and Metal Circuitboard Brackets

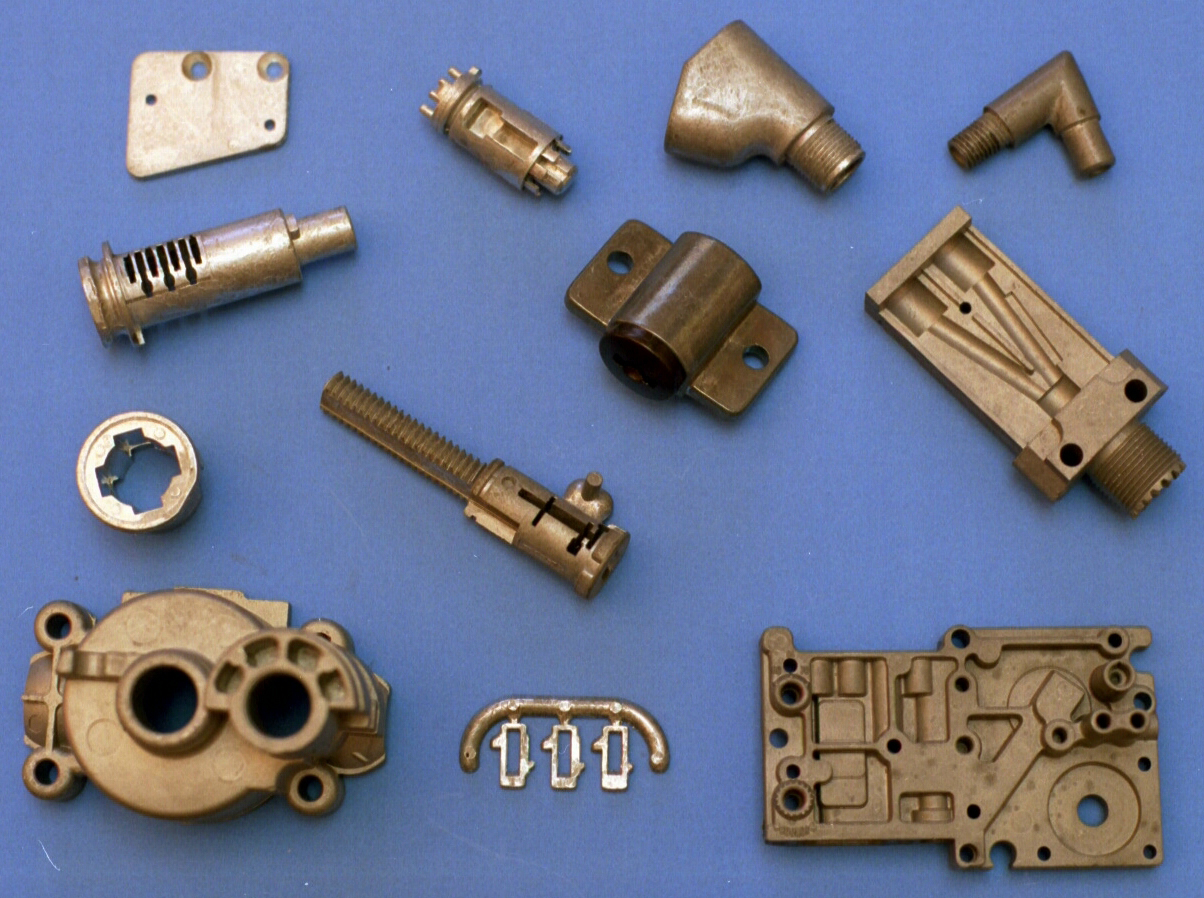

Exact tool has a unique niche in the manufacturing world. We are a metal stamper and a zinc die caster. To make long story short, many years ago we started producing a multitude of lock components. Locks contain many stamped and zinc die cast parts so we decided to expand and manufacture both metal stampings and zinc die castings to provide more of a one-stop shop for our customers. Exact Tool is not just limited to making parts for the lock industry. Exact Tool manufactures many types of zinc die castings, metal stampings and tools for all types of industries. Exact Tool builds it’s own high quality molds and stamping dies maintain control of the manufacturing process. All of Exact Tool’s products are all manufactured in the USA in our midwest Wheeling, Illinois facilities.

Stampings for the Lock Industry: Cams, Back-Plates, Washers, Spring Retaining Clips, & Keys of Brass, Steel & Zinc. ETCI Virtually Makes all Components for Locks. Zinc Die Castings: Lock Components, Air Transfer, Electrical & Automotive Components Electrical Component Enclosure, a Polymer Speaker Faceplate w/ Talk, Listen, Door Buttons and Metal Circuitboard Brackets State of the Art Techmire™ Four Slide Die Casting Machine

Exactcut software

Made with the same attention to detail, superior materials, manufacturing processes, and workmanship as their larger counterparts, these products offer uncompromising performance and efficiency in tissue resection.

On the stamping side, some of the things Exact Tool manufactures are progressive dies, lock components, such as, key blanks, steel cams, spring clips, retaining rings, brass tumbler wafers, back plates, and washers. Exact Tool also produces many stamped parts outside the security industry. Steel mounting brackets for computer / electronic circuit boards, stamped parts for office products, cabinet enclosures.

The disposable, sterile shaver blades can be used in all Arthrex shaver handpieces and inserted with the cutting window in the up or down position. Threads molded into the standard-size blade hubs allow them to lock onto bridge cannulas for increased maneuverability and improved fluid management.

ExactPipeCut 460 Pro Series

Made with the same attention to detail, superior materials, manufacturing processes, and workmanship as their larger counterparts, these products offer uncompromising performance and efficiency in tissue resection.

Exactpipe cut 360

For die casting, Exact Tool produces it’s own molds to run in it’s Techmire™ four slide & conventional zinc die casting machines. Exact Tool casts parts for the lock industry, including lock plugs and barrels. Exact Tool also produces zinc castings for construction equipment, transportation equipment, electronics and many other areas.

Exact Tool builds plastic injection molds to produce parts to compliment it’s metal stamping and zinc die casting operations.

CoolCut specialty-length shaver blades feature a wide range of high-quality, single-use shaver blades for arthroscopic surgical procedures of the ankle, wrist, and elbow.

The disposable, sterile shaver blades can be used in all Arthrex shaver handpieces and inserted with the cutting window in the up or down position. Threads molded into the standard-size blade hubs allow them to lock onto bridge cannulas for increased maneuverability and improved fluid management.

0086-813-8127573

0086-813-8127573