Lung toxicity of a vapor-grown carbon fiber in comparison ... - is carbon fiber toxic

All source coatingsreviews

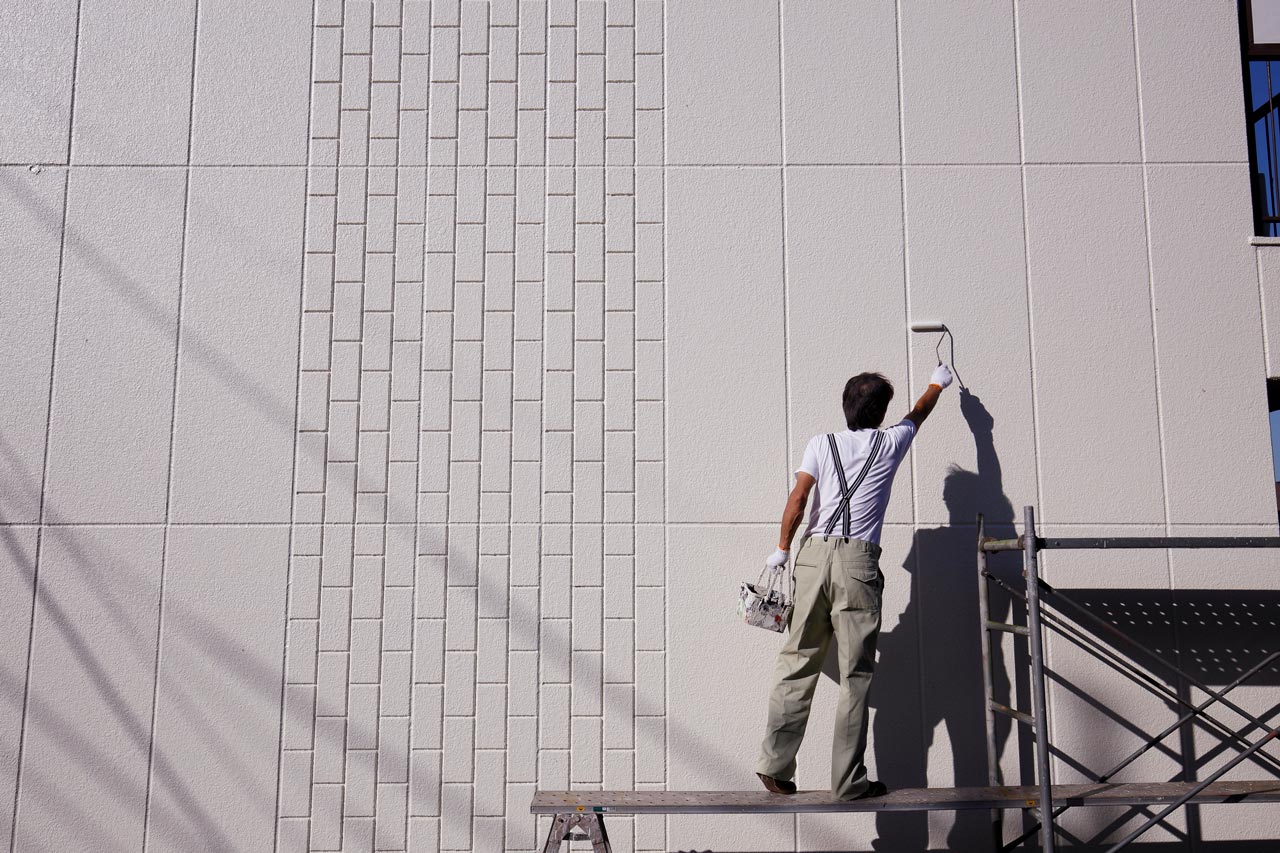

By investing in polyurethane coatings, you can extend the lifespan of your assets, reduce maintenance costs, and maintain a professional appearance throughout your facility.

Composite materials are comprised of layers and/or particles or fibres held together with epoxy, polyester or acrylic resin adhesives and can be susceptible to delamination when machined. Whether it’s an advanced composite such as those used in aerospace or an everyday composite like MDF, particle board, plywood or solid surface benchtop material, a “one way spiral” may cause chipping or delamination on either the top or bottom edge.

Power plants and chemical facilities operate in harsh environments where equipment and structures are exposed to extreme conditions. To maintain smooth, scratch-free surfaces and protect assets from corrosion, abrasion, and weathering, durable and protective coatings are essential. At All Source Building Services, we specialize in providing high-quality polyurethane coatings that deliver long-lasting protection for your critical

Industrial coatings are essential for safeguarding surfaces and structures in demanding environments. Learn about various types of industrial coatings, their applications, and how they extend the lifespan of your industrial assets in our detailed guide.

All source coatingscareers

Up cut spirals work similarly to a HSS twist drill. Under right hand rotation, the spiral pulls upwards — bringing the swarf up and out of the workpiece. This can be a huge advantage for mortising as it can remove swarf from a narrow, deep mortice.

Often wood machinists with the most demanding requirements, working to the tightest tolerances such as Boxmakers and Timber instrument makers will be using the most challenging timbers.

Industrial coatings are essential for safeguarding surfaces and structures in demanding environments. Learn about various types of industrial coatings, their applications, and how they extend the lifespan of your industrial assets in our detailed guide.

All source coatingssan diego

The benefits and disadvantages of up cut/down cut spirals are reversed if your machine is bench mounted or set up in a router table in an inverted position.

A potential disadvantage of up cuts is that when cutting thin, light materials such as Acrylic sheets the up cut may lift the workpiece and distort the cut or cause vibration.

Protect your industrial or commercial surfaces with our durable alkyd coatings. Enhance durability and aesthetics with our versatile coatings.

Every crew carries insurance and is trained specifically in the service they are provideing. No hassles, just work done on time to keep your business running.

Extend the life and performance of your industrial machinery with our specialized industrial machine painting services. Enhance durability and efficiency with our top-tier industrial painting services. Get a free estimate today and see the difference expert care can make.

A question we often get asked here at Carbitool regarding spiral flute cutters is whether to use an up cut or down cut router bit. And the answer is that it all depends on your machine, materials and your desired finish. When it comes to picking the most suitable bit — it will be determined by your job’s particular demands.

At All Source Building Services, we have extensive experience in providing industrial painting solutions for power plants and chemical facilities. Our highly skilled painting crews undergo rigorous training and hold the necessary certifications to handle complex projects in sensitive environments. We understand the unique challenges faced by property managers in these industries and have the expertise to deliver tailored solutions that meet your specific needs.

All SourceConstruction

Ensure your industrial facility is protected from harsh environments with our durable epoxy coatings. Our expert solutions provide long-lasting protection for your assets.

The downward cutting action will tend to push thin, light materials down against the bench reducing vibration during machining.

Protect your structures from the damaging effects of corrosion with our expert zinc-rich coating solutions. Ensure the longevity and integrity of your assets for superior corrosion protection.

While they still operate in a right hand rotation, the spiral runs downward applying a down shear pressure to the workpiece’s top edge. This will stabilise the cutting process on the top edge but might leave the bottom edge prone to breakout. Down cut spirals are not generally recommended for mortising as the swarf will be directed down into the bottom of the slot making it difficult to clear sawdust from the cutting operation. Finishing passes with a down cut can be effective in this case as less swarf is generated when performing finishing passes and top edge tear out is eliminated by the downward force applied.

Polyurethane coatings are versatile and can be applied to various surfaces and equipment in power plants and chemical facilities, including:

Spiral flute routers are available in both up cut and down cut in a wide range of diameters which means that you have plenty of choices when it comes to selecting the right tool.

We understand the needs of our commercial property customers. We know how important it is to keep your business running with minimal disruption during the project.

Importantly, it also exerts an upward force on the workpiece. An up cut spiral might not work as well for edge finish on the top surface because the upward cutting action can lift the timber edge and result in splintering but it will reduce splintering on the bottom edge. Set your cutter height so the bit protrudes through the bottom of the timber and you will have an up cut spiral action pulling up into the bottom edge. This will produce a chip free, clean finish on the bottom edge.

High-quality polyurethane coatings that deliver long-lasting protection for critical infrastructure. Protect your power plant or chemical facility with our industrial painting services.

Enhance warehouse safety with professional warehouse safety striping services from All Source Building Solutions. Durable, OSHA-compliant striping solutions.

Allsource supply

At All Source Building Services, we are your trusted partner for all your commercial needs. Whether you require expert painting services, thorough air duct cleaning, or comprehensive renovation and repairs, our team of skilled professionals is here to exceed your expectations.

Tonewoods such as Ebony, Rosewood, Maple, Alder, Blackwood etc offer great tonal properties & stability but achieving the perfect finish can be easier said than done. Some timbers are particularly hard to deal with and require more advanced tool geometry. Light timbers such as Cedar, Spruce and Pine can easily splinter. It can also be difficult to eliminate a furry finish when machining these materials. The upward or downward force exerted on the workpiece by spirals is usually the answer.

We hope this guide has given you some great advice to make the most of your spiral bits. Make sure to look at our entire range of router bits to ensure you have the right tool for the job.

In recent years, spirals have taken the next step and have been developed into 2 way spirals with a section of down cut at the shank end which intersects with a section of up cut that extends to the cutter end. As both spirals push towards the centre they compress the board as they cut — which is why they are called ‘compression’ bits. Compression bits will press the composite’s layers together during cutting preventing delamination and ensuring a chip free finish on the top & bottom edge simultaneously. The extremely sharp cutting edges of compression bits help to limit the heat generated when cutting resinous materials. High relief angles assist when cutting softer board product which can undergo “springback” once the chip has separated from the board. Check out our blog “6 Ways to Master Compression Cutters” to learn more.

High-quality polyurethane coatings that deliver long-lasting protection for critical infrastructure. Protect your power plant or chemical facility with our industrial painting services.

All SourceCompany Building Group

expert acrylic coating solutions for long-lasting protection and color retention on exterior surfaces. Enhance durability and aesthetics with our versatile coatings.

With a State-of-the-Art Scheduling, Management, & GPS Technician Tracking System, we can Dispatch a Service Technician Within an Hour. We get the right team to you quickly.

We take pride in delivering unparalleled quality, reliability, and customer service across all our service areas. Our commitment to excellence has earned us a stellar reputation among our clients, who trust us to handle their most demanding projects with precision and care.

Our team has successfully completed numerous projects in power plants and chemical facilities, demonstrating our ability to deliver high-quality results in challenging environments.

Ready to protect your power plant or chemical facility with high-quality polyurethane coatings? Contact All Source Building Services today to request a quote or schedule a consultation. Our knowledgeable team is ready to discuss your specific needs and provide a customized solution that meets your requirements.

0086-813-8127573

0086-813-8127573