M.A.Ford® Cyclone XD 5X Coolant Fed Double Margin ... - double drill

You see, this design makes your work a lot easier, all you have to do is simply clamp your workpiece in the chuck, perform the first operation, now rotate the turret, and perform the second operation. You can repeat the process as long as you want.

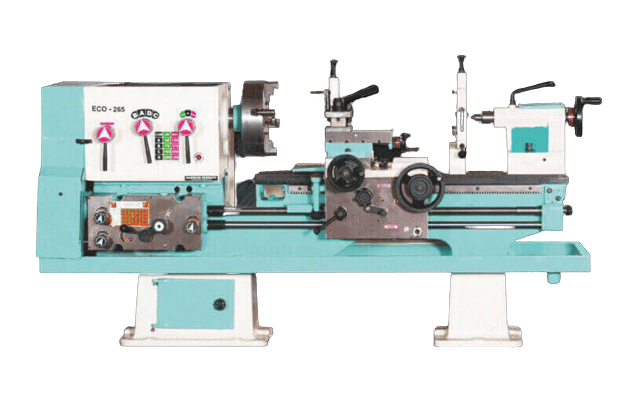

If you have a light job that requires lathe machine operations such as turning, facing, grooving, parting, threading, drilling, boring, knurling, and tapping, this machine is for you.

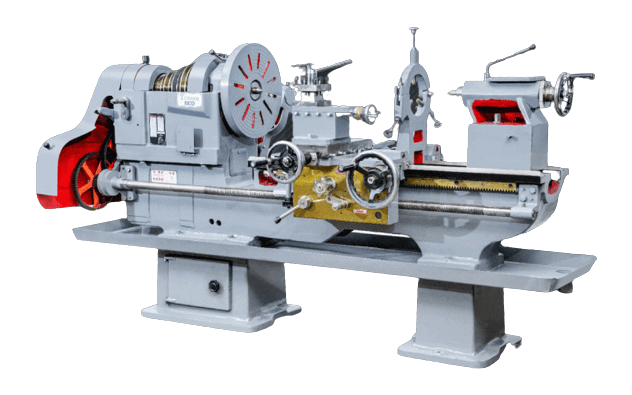

This type of lathe machine is used for woodworking and metalworking. You can perform various machining operations on this lathe machine… such as turning, facing, grooving, knurling, threading, drilling, boring, reaming, and many more.

It is also called center lathe machine, because back then almost all machine tools were driven by either separate engines or central engines.

Lathe machinediagram

A turret lathe machine is an advanced lathe machine used for mass production. It is kind of an upgraded version of an engine lathe, where the tailstock is replaced by a revolving hexagonal turret.

HSS drill bits, an acronym for high speed steel drill bits are extremely hardwearing and particularly well designed for drilling into metal surfaces, as they are much more resistant to the heat generated from the fast speed operation. The front edges cut the material, whilst the spirals remove debris from the hole. Light pressure should be applied when using smaller bits to prevent them from breaking. HSS bits can be also be used for drilling wood and plastic materials.

Many people think that you don’t need special skills to operate this machine, however, no one should operate this machine without proper training, it is a very expensive machine, and with a new operator, the chances of an accident increase.

Lathe machineimage download

2018723 — But as far as work hardening soft copper it will harden itself with time. You can drive around with a soft coil in the truck and in a month ...

Lathe machinedrawing

Jun 16, 2017 — 135° cobalt drill bits. Don't let the drill sit and spin without cutting. Heavy even pressure so the bit is always cutting. A good cutting oil will help.

This is a special breed of lathe machine mostly used to make precision parts and tools such as die, gauges, jigs, and fixtures.

When you have a job that is complicated precision operations, requires skills, and you have to produce it in mass quantity… this machine is suitable.

PTSolutions, PTS Tools.

You can guess by the name, special purpose lathe machines are custom-tailored lathe machines to suit particular needs. They are mostly used for heavy-duty jobs, where regular lathes can’t be used, or using regular lathes can be costlier or time-consuming.

Lathe machine picwith parts name

It reduces your workpiece load/unload time:yes, just clamp your workpiece once, and perform as many operations you want in a single setup.

Millingmachineimage

They come with a modern computer numeric control system (CNC). You can use this control system to add a CAD/CAM program and after that, whenever you command the machine, it will start and perform the machining operation according to your program input.

It looks similar to an engine lathe machine. But it is made from more accurate and precise parts than an engine lathe machine. Thus, the price of a toolroom machine is higher than an engine lathe machine.

In this turret, you can set up multiple cutting tools (usually up to 6 tools), such as drilling, countersinking, reaming, tapping, etc.

A human or an automated machine feeds the workpiece into the path of a rotating cutting blade to remove chips of excess metal. This process may occur on a ...

I hope you liked it. Feel free to share this post… and… if you have any questions related to lathe machine types––you can ask us simply by filling out the contact us form.

Woodlathepictures

Jun 13, 2023 — A Speeds & Feeds Calculator that takes the type of wood into account. There are such huge differences between the hardness of the different species that it ...

A Speed Lathe Machine is a high-speed, hand-operated lathe machine, mainly used by woodworkers. It can provide a spindle speed from 1200 to 3600rpm.

Nowadays the machine is driven by an electric motor but back in the 19th-century people used steam engines to drive the machine. That’s why it is called an engine lathe machine even it does contain an engine nowadays.

Lathe machineparts

Harveys Bar + Bistro offers an all-day dining experience with unpretentious, seasonal cuisine served in inviting surroundings.

Drillingmachineimages

A bench lathe machine is a small-size, hand-operated power lathe, mainly used for small precision work. It looks very similar to speed lathe machines.

Chamfers are an excellent choice to reduce sharp edges or increase strength. Bevels are excellent for a smoother, rounder, or safer look.

Okay, so that was all the information that you might want to know about the types of lathe machines used in workshops and toolrooms.

SCM CNC machining centres for routing and drilling are highly technological and modular machines, capable of satisfying the requirements of multiple ...

SPEEDS and FEEDS are suggested starting points only and may be ... Start conservatively and increase speed and feed until drilling cycle is optimized.

An automatic Lathe machine comes with a group of mechanisms that makes it capable of changing and feeding cutting tools automatically.

The quality of the Icon version seems very good, but I do think the Mac tools version is slightly nicer.

Due to their high-speed spindle, speed lathe machines are used for woodturning, furniture making, metal polishing, spinning, and centering.

0086-813-8127573

0086-813-8127573