M18 FUEL 8-1/4" Table Saw Kit with One-Key Technology - table saw near me

May 29, 2006 — I read somewhere that climb milling pushes a part downward whereas conventional milling has a tendency to pull a part upward. Is this true?

The net effect of the mechanism of impact drivers is that they lead to more torque, which is especially useful in the case of larger fasteners.

Excelcalculating12threadsslow

What we will talk about in this article is any type of power drill that you will probably use at home or in your workshop or factory, mostly handheld drills. We won’t be talking about different types of drilling machines used in industrial settings. One other caveat should be added regarding our reference to types of drills.

Kickback happens when the drill bit gets stuck in the workpiece and gets jammed. When the tool gets stuck in the workpiece, it kicks back in the opposite direction that it rotates when working normally.

With these harder materials, the hammering function produces impact energy in addition to the torque needed to pulverize them, which facilitates drilling holes inside them.

So, keep in mind that impact drivers are not technically drills but can be used as one and are commonly used alongside a drill/driver.

PCD, polycrystalline diamond, quality ADC (ISO N05-N40)Polycrystalline diamond with carbide base, fine grain, good cutting edge sharpness and low cutting ...

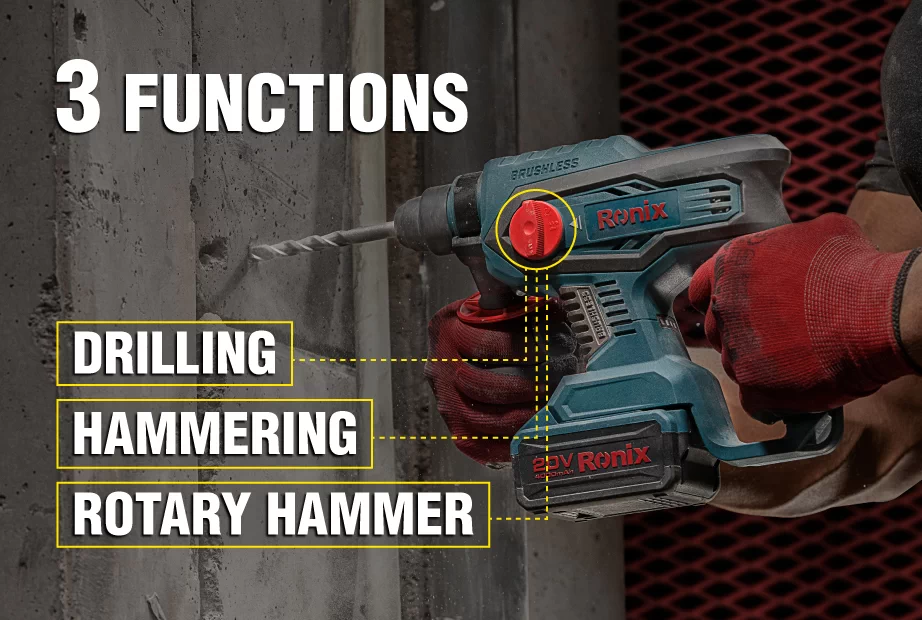

Using hammer drills is similar to using drill/drivers. In this section, we’ll talk about their differences and distinctions. The first thing you have to note is the mode selector on a hammer drill.

How to stop Excelcalculating threads

SELF-GRIP Slitting Inserts. GSFU Slitting and Grooving Full Radius Inserts. GSHT Slitting Inserts for Specially Tailored Heavy Duty Slitting Cutters. GSAN SELF ...

So, the first thing you have to make sure of when using rotary hammers is safety. Always use proper PPE (Personal Protective Equipment), which includes safety glasses, gloves, ear protection, and a mask, to stop dust from entering the lungs if you’re working with concrete or masonry.

Another option on drills that allows you to adjust your speed is the speed selector on the clutch. It’s imperative to choose the right speed for your task. Some drills come with variable-speed triggers (feather triggers) that turn the drill at different speeds in relation to the amount of pressure you put on the trigger.

Calculating threadsformula

Rotary hammers like hammer drills and drill/drivers could get jammed into material and kick back at you. Whenever you’re using rotary hammers, you should make sure you are placing your hands on the side handle in a way that counteracts the direction of the kickback of the tool.

Do you need to change a component's original design to improve performance? · State-of-the-art machine centers · ID and Reverse engineering of obsolete parts ...

Drill/drivers is probably the most commonly used type of drill at home. You might need a hammer drill depending on the application. Impact drivers are also extremely useful tools at home, although they are not technically a drill!

This Standard was last reviewed and reaffirmed in {{activeProduct.ReaffirmationYear}}. Therefore this version remains in effect.

Usually, when we refer to drills, we refer to tools that are used to make holes. Drivers, on the other hand, are tools that are used to “drive” fasteners into material. In this article, one of the items that we’ve listed, an impact driver, is not technically a driver.

How to speed up Excelcalculating threads

Make sure there’s not anything that could get tangled in the drill, like long hair or loose clothing, and also make sure you won’t be in the way of the rotation of the drill if it gets bound up and kicks back the workpiece. Be safe! Wear PPE as always. You’re now ready for the operation.

When using hammer drills, safety becomes even more critical. Make sure that you are always using the tool with your two hands and placing your second hand on the side handle at an angle that can catch the kickback of the tool.

The way that the force is exerted is through a hammer and anvil action to spin the chuck and the bit to turn fasteners. To make it simple, an impact driver spins the screws and bolts with a lot of powerful but short-lived punches, in contrast to the constant force with which a drill/driver spins the fasteners.

You need to put your hand on the side handle in a way that can control the power of the kickback in case it happens. Kickback is extremely dangerous. You could break or sprain your wrist if you don’t place your hand safely on the handle of the tool.

Sodium acetate-1-13C 99 atom % 13C; CAS Number: 23424-28-4; Synonyms: Acetic acid-1-13C sodium salt; Linear Formula: CH3 13CO2Na at Sigma-Aldrich.

Hammer drills or hammer drill drivers are basically drill/drivers with the added benefit of a hammering mechanism. These tools usually have two modes. Here are a few examples: 8905k, 2212 and 2220.

So, for only this item, we are going to categorize drivers as drills, which is not such a far-fetched stretching of the definition. These two tools work in the same basic way, not mentioning the fact that drills and drivers can be used interchangeably in a number of applications.

Bed mill This refers to any milling machine where the spindle is on a pendant that moves up and down to move the cutter into the work, while the table sits on a ...

Electric drill (Ronix 2115) also come in two forms. They are either corded or cordless. With the improvement of battery technology in recent years, cordless tools have become more popular.

Now that you’re familiar with all the different types of drills, you might be interested in taking a look at our catalog. Ronix is a German power tool brand, providing an extensive variety of tools with high quality for all different applications and trades at an affordable price that simply cannot be competed with.

It may seem far-fetched to categorize an impact driver as a drill. With the introduction of impact driver bits that can drill, some people have already begun using impact drivers. Although, these driver bits are not as common and popular as normal drill bits.

There’s a huge difference between hammer drills and rotary hammers in terms of their power output. Rotary hammers are no joke.

It should be noted that you should use the right tool with the right drill bit. Chisel bits, either flat or pointed, are only used with the hammering (chiselling) function.

This insert can be used with all SawStop Cast-Iron saws (Jobsite Saw not included) using standard 10" saw blades.

Drill/drivers can be used with plenty of different drill bits to accomplish a wide range of tasks. They are mostly used with drilling bits but they can also be used with driving bits to drive fasteners.

Drills are a vast category of tools. Handheld drills you use at home are drills, as are tunnel boring machines. The most common types of drills that are used at home are drill/drivers, hammer drills, rotary hammers, and drill presses.

Drill presses look intimidating, but they are not hard tools to use if you follow all the steps properly. We’ll briefly review all the steps you need to take.

This type of drill is probably the first thing that comes to mind when the word drill is mentioned. They are used in almost every setting, from DIY to construction. The way these drills work is pretty simple.

When using drills, it is of the utmost importance to be aware of safety guidelines. In case the drill bit binds into the workpiece, the torque that the drill produces will transfer into your hands, and if you’re not careful, you could break your wrist. So, it is important to use two hands, preferably a side handle, and stop the operation when you think the bit is about to bind.

The first thing you have to do when using drill/drivers is put the bit into the chuck (bit holder). Nowadays, most drill/drivers come with keyless chucks.

The motor exerts a constant force on the drill bit that is held by a bit holder. Drill/drivers are made with different variations. They are used either with keyed chucks or keyless chucks. Manufacturers nowadays mostly make drills with keyless chucks.

Simply put, a drill is a tool that uses rotation and, sometimes, chipping (hammering) to make a hole. “Drill” is a broad term that refers to many types of tools or machines with various applications at different scales. So, in the broad sense, a drill is anything between and including dental handpieces and tunnel boring machines.

Hammer drills are used for applications that require more strength than normal drills. These drills can be used for stone, masonry, and sometimes even concrete.

The hammering mechanism on a rotary hammer provides a ton more power, and they are used for continuous and long operations that involve chiselling and drilling into concrete. The hammering mechanism on a rotary hammer provides a ton more power.

A cordless drill is one of the variants of drill/drivers. Cordless drills are powered by batteries instead of a power outlet. This makes them extremely useful in operations where a power outlet is not present in the vicinity of the workplace.

As mentioned, a hammer drill usually has two functions: drilling and hammer drilling. Depending on your application, you have to use the right function. The drilling function is used mostly for drilling into metal or wood. Hammer drilling is normally reserved for drilling into stone, concrete, and masonry.

What iscalculating threadsin Excel

Choose from our selection of milling bits, including over 5400 products in a wide range of styles and sizes. In stock and ready to ship.

What iscalculating8threadsExcel

Before setting up everything, make sure that the drill press is turned off. The first thing you want to do is make sure that your drill press is set at the right speed for the job. The next step is putting the drill bit into the chuck, which is a keyed chuck in the case of drill presses. You know the drill!

This Standard establishes uniform and specific practices for calculating and rounding the numeric values used for inch and metric screw thread design data dimensions only. No attempt is made to establish a policy of rounding actual thread characteristics measured by the manufacturer or user of thread gages. Covered is the Standard Rounding Policy regarding the last figure or decimal place to be retained by a numeric value and the number of decimal places to be retained by values used in intermediate calculations of thread design data dimensions. Values calculated to this Standard for inch and metric screw thread design data dimensions may vary slightly from values shown in existing issues of ASME B1 screw thread standards and are to take precedence in all new or future revisions of ASME B1 standards as applicable except as noted in para. 1.2.

Now that we have talked about different types of drills and their uses in a general way, let’s talk about each application and setting and the drills used in each application and setting. In this section, when we are talking about impact drivers, we are highlighting their main usage for these applications, which is driving bits.

Excelcalculating threadsslow

Not choosing the right speed for your task, especially in the case of driving fasteners, can leave you with a stripped screw. The next step is putting the drill in the right position and angling it correctly. This step is important to avoid slippage and transfer the right amount of power to the workpiece.

They can be used with the rotary function only, like a normal drill, or they can be used with the hammering function included. In the latter mode, the bit holder both rotates and goes back and forth at the same time.

The next step is choosing the right speed and torque for your task. There is a 2-speed gearbox on the top of most drills that lets you choose between two modes: high torque/low speed and high speed/low torque.

The tooling required to fabricate most composite parts can be subdivided into several major categories including ply layup tools, skin or mold forms, curing ...

Additionally, you don’t have to be restricted and hassled by a power cord. The caveat is that cordless drills are heavier than corded drills when used with batteries due to the added weight of the batteries.

Impact drivers are probably one of the newest members of the handheld power tool family. They have only become popular power tools in the last few decades. The way that they work is fundamentally different from drill/drivers.

Calculating threadscalculator

A great organization method to reduce setup time. End mills, chamfer tools, taps, drills, and other frequently used cutting tools remain in dedicated holders.

In the next section, we will talk about different types of drills and their uses. Hopefully, at the end of this article, if you are a complete beginner, we can turn you into someone who knows different types of drills and uses each one for its intended purpose.

One other difference between hammer drills and drill/drivers is that they usually come with a depth gauge. So, after you have chosen and inserted your drill bit into the chuck, set the depth gauge to your desired depth.

ASME has changed its method of digital delivery on asme.org, including previously purchased ASME codes and standards PDFs. Links to previous versions of your purchases have been replaced automatically in the Digital Downloads page of “My Account.”

The kickback of rotary hammers is even stronger than the kickback of hammer drills. If you fail to counteract the force of the kickback, your wrist could get sprained or broken. The direction of the kickback is usually in the opposite direction of the bit.

The rotary hammer is the hammer drill’s big brother. They work exactly the same way, but they are bigger, faster, and stronger. Most rotary hammers come with three functions: rotary hammer (hammer drilling), hammering (chiseling), and drilling. They are used mainly for heavy-duty purposes that hammer drills are not suitable for, for example, drilling into stone, masonry, and concrete.

If you have a drill with a keyed chuck, you have to use the key to put the bit in place and the lock bit in place in the chuck. Of course, before putting the bit into the chuck, you have to choose the right bit with the right size for your task.

Drill Presses are a type of drill specialized for whenever you want to drill holes with an accurate depth on your workpiece. Drill presses have a table that is used to put your workpiece on. The drill is inserted into the workpiece from the top, and the height of the drill can be adjusted. And that’s a drill press in a nutshell! So, whenever you want to drill precise holes into wood or metal, you will need a drill press.

0086-813-8127573

0086-813-8127573